Cell-based biosensor, preparation method thereof and method of evaluating oxidation resistance by employing same

A technology of cell sensor and anti-oxidation ability, applied in biochemical equipment and methods, screening of compounds, detection of programmed cell death, etc., can solve the problem of inability to fully simulate the cell microenvironment, incomparable test results, and large differences in subjects and other issues, to achieve the effect of shortening the research cycle, short training cycle, and small differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] a), preparation of acidified manganese dioxide: MnO 2 Dissolve in concentrated H in an ultrasonic (ultrasonic condition: 100KHz, time 5min) bath 2 SO 4 and concentrated HNO 3 (the massfraction of concentrated sulfuric acid ≥ 70%, the massfraction of concentrated nitric acid is about 68%) obtains mixed solution in the combined acid solution, then mixed solution is stirred 3-5h in ice bath (0 ℃), centrifugal, washing and After drying, a-MnO was obtained 2 (acidified manganese dioxide) nanomaterials;

[0047] b), preparation of modified electrode: a-MnO 2 Nanomaterials are dispersed in chitosan solution under ultrasonic (ultrasonic conditions: 100KHz, time 8min) to obtain a suspension with a solid phase concentration of 0.9-1.1mg / mL, and then 8-12μL of the suspension is dropped on the surface of a dry gold electrode Above, the modified electrode was obtained after drying at 4-6°C;

[0048] c), the preparation of the mixed gel: the graphene oxide is mixed with the DME...

Embodiment 1

[0055] Example 1 Control group

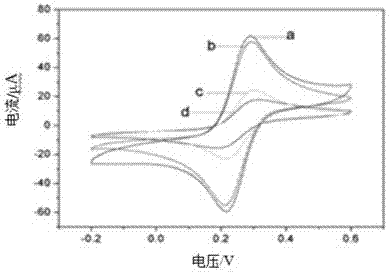

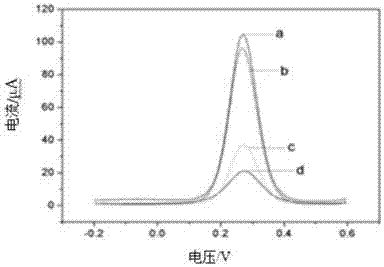

[0056] Positive control: put cell sensor one in Tyrode buffer at 37°C (Tyrode solution preparation: 1000ml Tyrode solution contains: NaCl 8.0g, 10% KCl 2.0ml (0.2g), 10% MgSO 4 .7H 2 O 2.6ml (0.26g), 5% NaH 2 PO 4 .2H 2 O1.3ml (0.065g), NaHCO 3 1.0g, 1M CaCl 2 1.8ml (0.2g), glucose 1.0g), add PMA to make the concentration 100ng / mL, let it stand for 10 minutes, wash 3 times with PBS buffer (phosphate buffered saline) of pH=7.4, and then the cells Sensor one is connected to the electrochemical workstation, in the presence of 1.0mM Fe(CN) 6 3- The cell sensor in the solution is detected by electrochemical method, and the current signal I is recorded 0 = 84.6μA;

[0057] Blank: Cell sensor three was placed in Tyrode buffer at 37 °C, washed 3 times with PBS buffer after 10 minutes, and then connected to the electrochemical workstation, in the presence of 1.0 mM Fe(CN) 6 3- The cell sensor 3 was detected electrochemically in the solution...

Embodiment 2

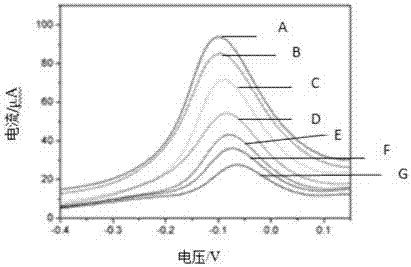

[0058] Embodiment 2 Lactobacillus plantarum NJAU-01

[0059] 1) Preparation of bacterial solution: Lactobacillus plantarum NJAU-01 isolated from Chinese traditional fermented ham was used to inoculate fermented sausage as the initial culture. It was identified by API 50CHL kit (bioMérieux Inc., France) and 16S rDNA sequencing analysis. Lactobacillus plantarum NJAU-01 strain was grown in MRS broth at 37°C for 18h. First, bacterial cells were harvested, washed and resuspended in deionized water. Adjust the cell concentration to 10 5 , 10 6 , 10 7 , 10 8 , 10 9 and 10 10 CFU / mL. Next, the cells were incubated with 1 mg / ml lysozyme for 30 min at 37°C and then sonicated in an ice bath. After removing cell debris by centrifugation (8000 g, 10 min, 4° C.), the supernatant was obtained as Lactobacillus plantarum NJAU-01 bacterial liquid.

[0060] 2), pretreatment: put Lactobacillus plantarum NJAU-01 bacterial liquid and cell sensor II in Tyrode buffer at 37°C, then add PMA t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com