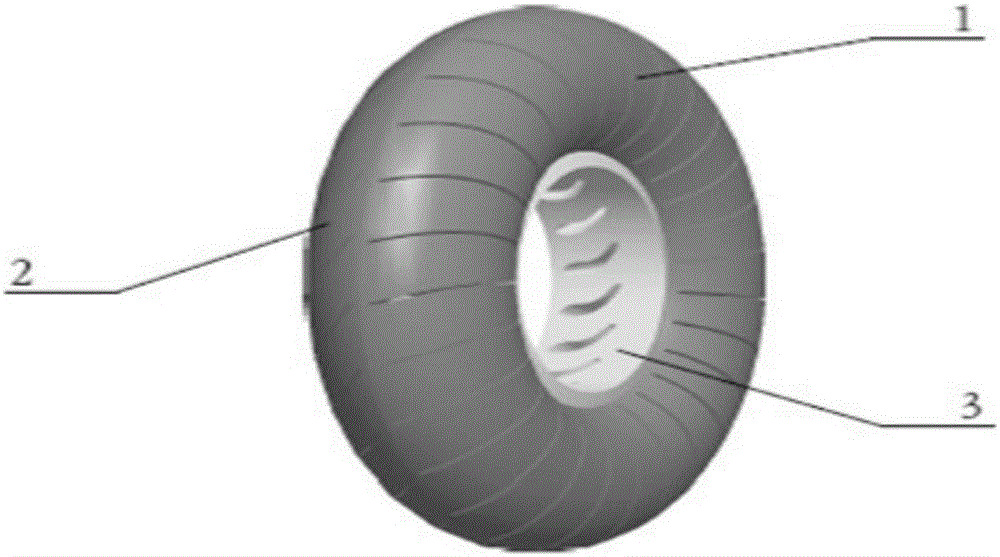

Optimization method for automobile hydraulic torque converter

A hydraulic torque converter and optimization method technology, applied in the direction of instruments, genetic rules, electrical digital data processing, etc., can solve the problems of high cost, heavy workload, and long research cycle, so as to reduce workload, The effect of optimizing comprehensive performance and reducing R&D and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

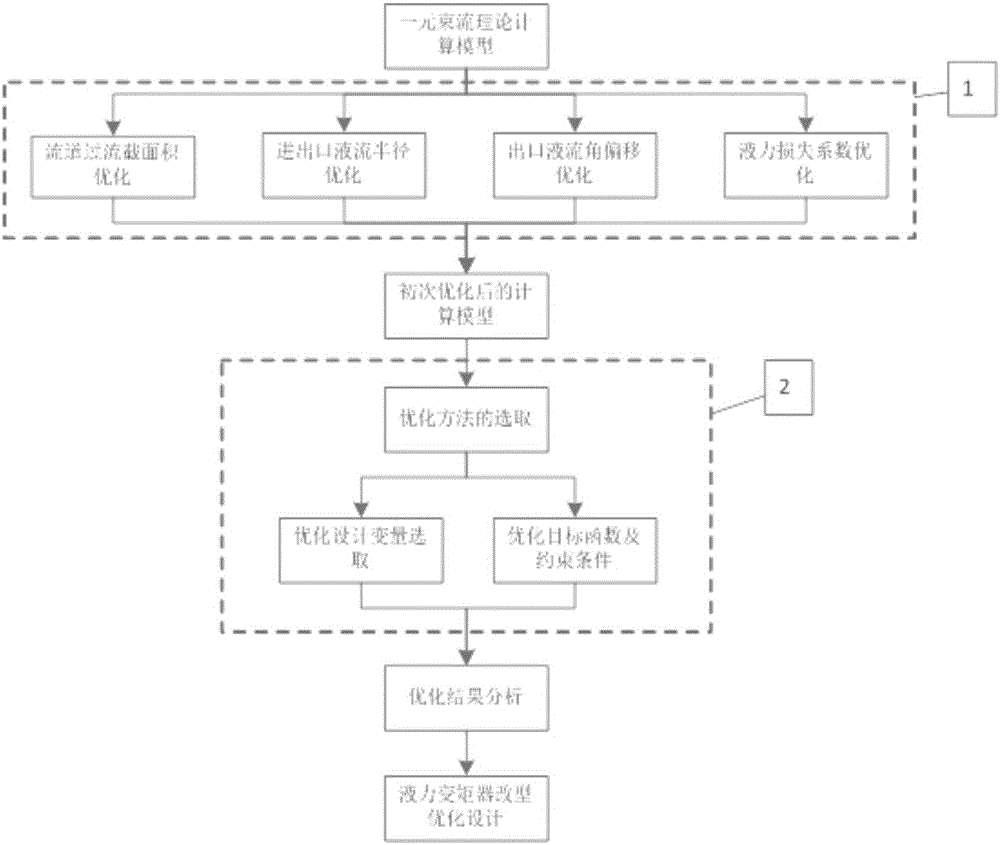

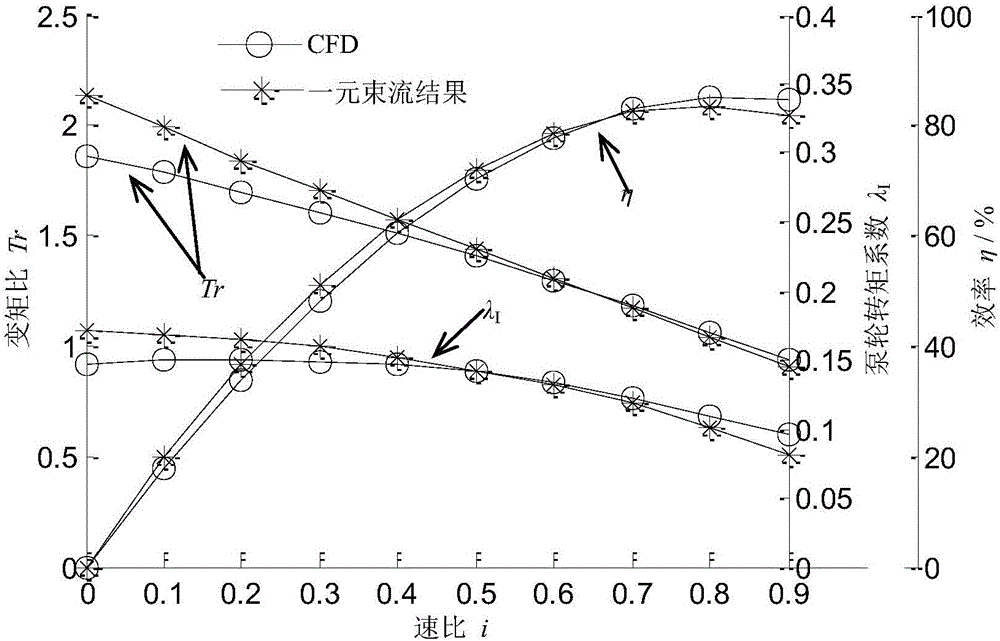

[0030] The invention uses the theoretical calculation model of the unitary beam current of the hydraulic torque converter as the basic model to optimize the design. The calculation model of the unitary beam flow theory makes the following assumptions on the internal flow characteristics of the torque converter: 1) The liquid flow is equivalently concentrated in a streamline determined by the blade surface; 2) The flow at the outlet of the impeller is not affected by The influence of the flow state at the inlet; 3) The liquid flow state at the inlet of the latter working wheel is completely consistent with the flow state at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com