Hydrolysis-resistant ultraviolet (UV) photoaging resistant biodegradable plastic mulching film and preparation method thereof

A biodegradable plastic and biodegradable technology, applied in the fields of biodegradable plastic mulch, hydrolysis-resistant and UV-light aging-resistant biodegradable plastic mulch and its preparation, can solve the obstacles to large-scale production, complex mulch processing technology, and no concern for polyester degradation Control problems, etc., to achieve the effect of being beneficial to processing and molding, improving mechanical strength, improving hydrolysis resistance and UV aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to the preparation method of the hydrolysis-resistant UV aging-resistant biodegradable plastic film of the present invention, the preparation method comprises the following steps: (1) polylactic acid, biodegradable polyester, photoinitiator, photocurable polyester oligomer, polyester chain extension Agents, fillers, additives and color masterbatches are mixed evenly with a high-speed mixer in proportion, the speed is 100-600 rpm, and the temperature is not more than 60°C to obtain a mixture; (2) the mixture described in step (1) , use a twin-screw extruder to melt and plasticize, extrude and granulate to obtain pellets, barrel temperature: 140-200°C, head 160-170°C; (3) pass the pellets described in step (2) through Extruded by a single-screw extruder to form a film, irradiated by an ultraviolet light source with an irradiation power of 1-10mW / cm2 and an irradiation time of 1-120 seconds to obtain a hydrolysis-resistant and UV-resistant photoaging biodegradable...

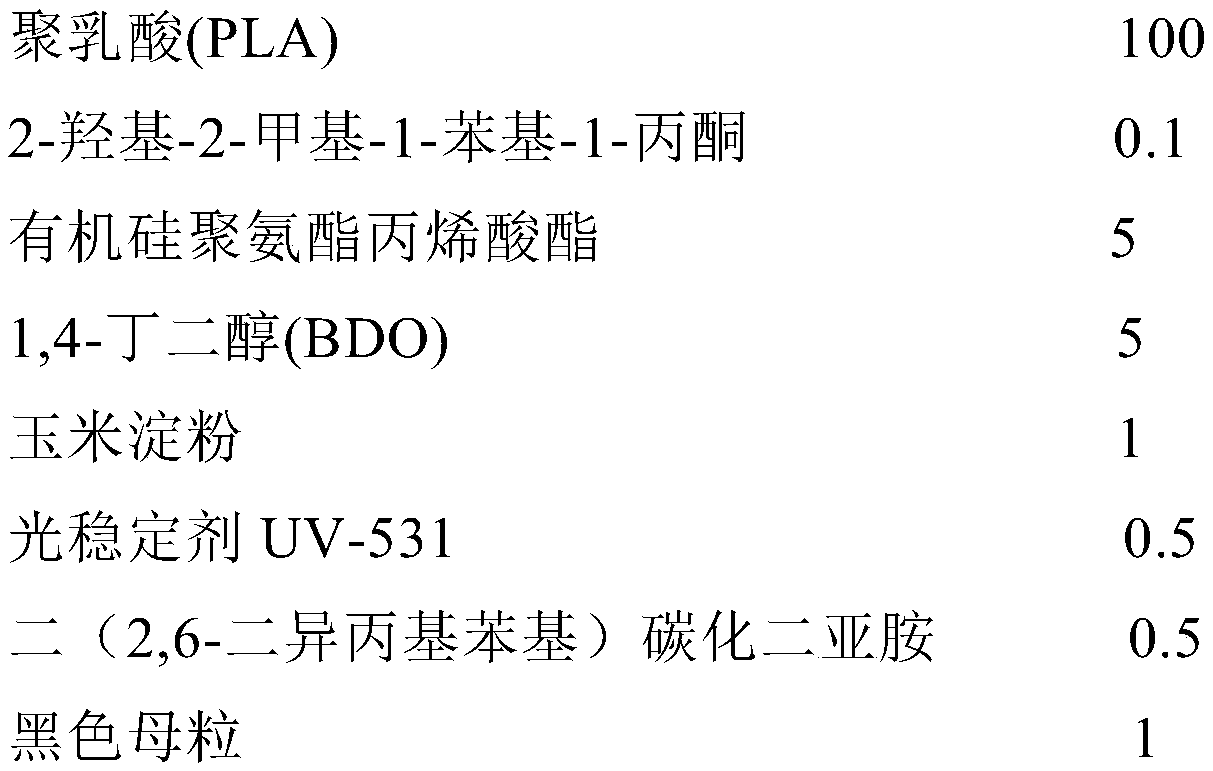

Embodiment 1

[0037] (1) Use a high-speed mixer to mix the uniform mixture in proportion, the rotating speed is 100 rpm, and the temperature is 40°C. The mixture includes in parts by mass:

[0038]

[0039] The composition of black masterbatch in parts by mass: 100 parts of polylactic acid (PLA), 20 parts of carbon black, and 1 part of EBS.

[0040] (2) Melt and plasticize the mixture described in step (1) with an intermeshing counter-rotating twin-screw extruder, extrude and granulate to obtain pellets, barrel temperature: 140°C, head 160°C;

[0041] (3) The pellets described in step (2) are extruded into a film through a single-screw extrusion casting machine, and then irradiated by a high-pressure mercury lamp, and the irradiating power is 1mW / cm 2 , with an irradiation time of 1 second, to obtain a hydrolysis-resistant, UV- and photoaging-resistant biodegradable plastic mulch film.

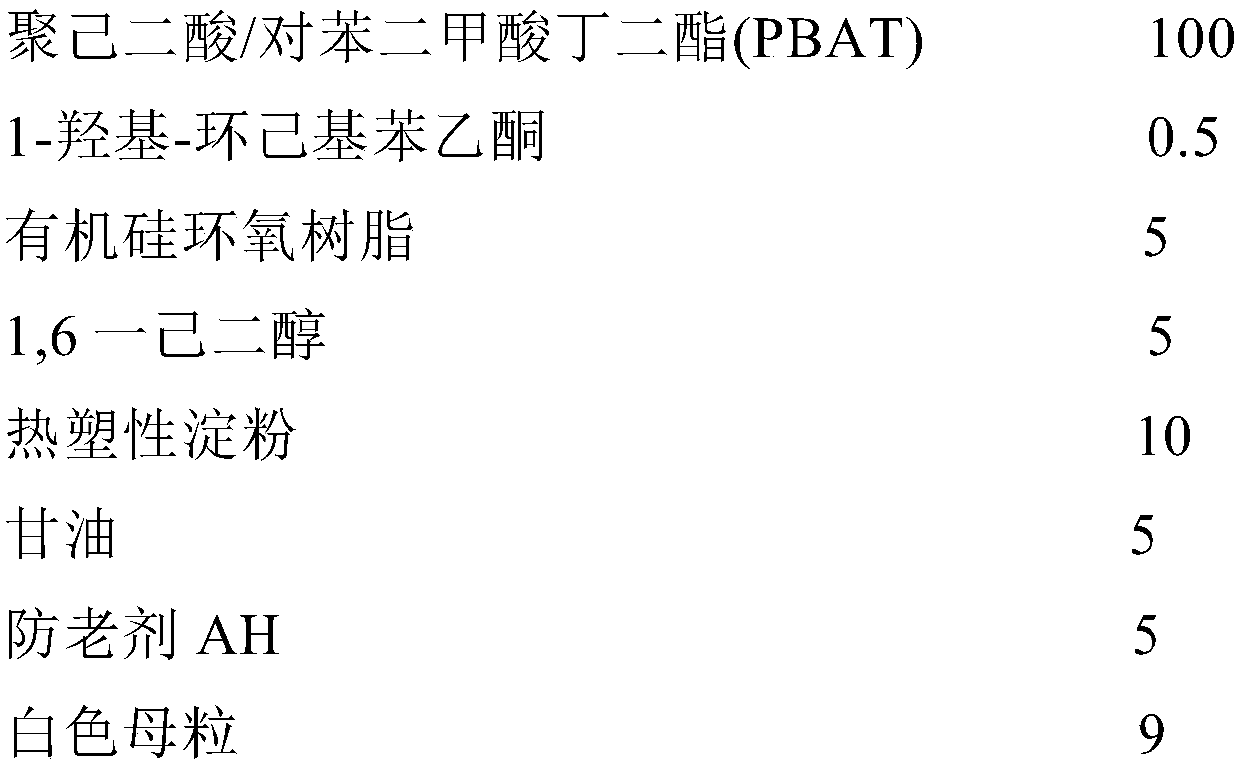

Embodiment 2

[0043] (1) Use a high-speed mixer to mix the uniform mixture in proportion, the rotating speed is 600 rpm, and the temperature is 50°C. The mixture includes in parts by mass:

[0044]

[0045] Described white masterbatch, by the composition of mass parts: 100 parts of polyadipate / butylene terephthalate (PBAT), 40 parts of titanium dioxide, 3 parts of ethylene bis stearic acid amide (EBS);

[0046] (2) Melt and plasticize the mixture described in step (1) with an intermeshing co-rotating twin-screw extruder, extrude and granulate to obtain pellets, barrel temperature: 200°C, head 170°C;

[0047] (3) The pellets described in step (2) are extruded into a film through a single-screw extrusion blown film machine, and processed by xenon lamp irradiation, and the irradiation power is 10mW / cm 2 , with an irradiation time of 120 seconds, to obtain a hydrolysis-resistant, UV-resistant and photoaging-resistant biodegradable plastic mulch film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com