Building rubbish pavement base material and preparation method thereof

A technology of pavement base materials and construction waste, which is applied in the field of road materials to achieve dry shrinkage, improvement of poor quality, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

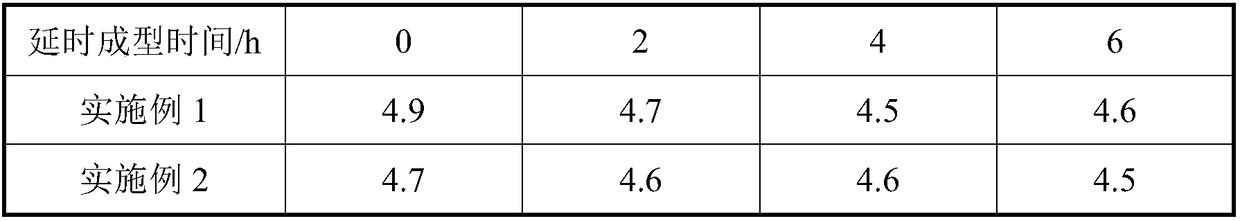

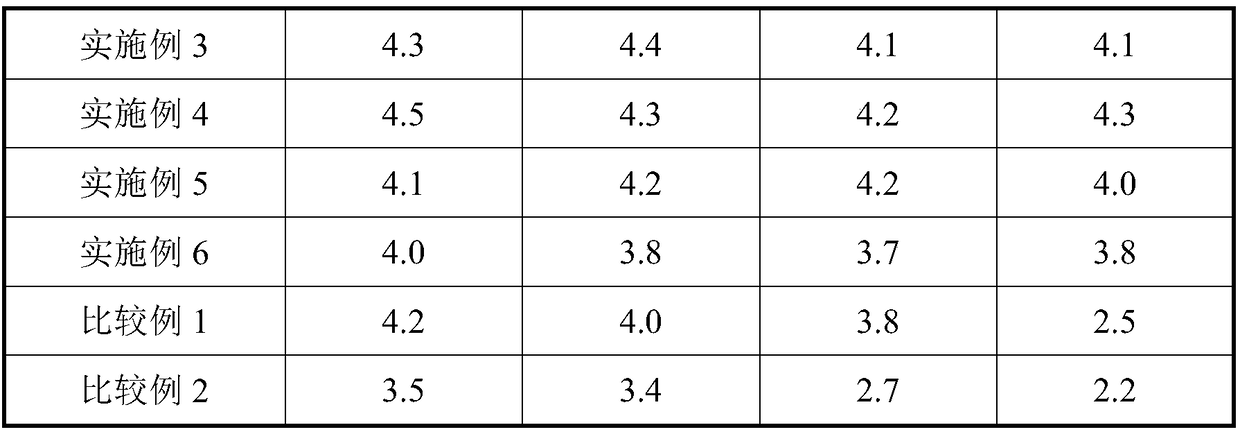

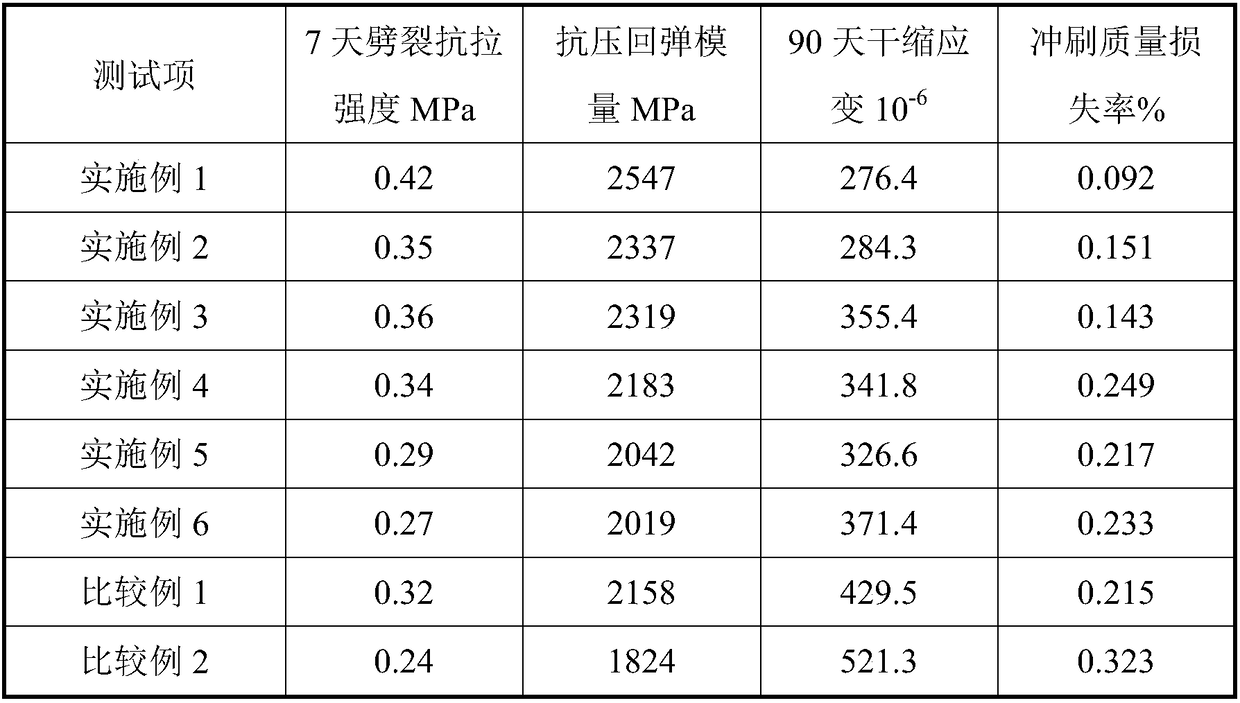

Examples

Embodiment 1

[0048] This embodiment relates to a construction waste pavement base material and a preparation method thereof, the method material is composed of 96% mass fraction of concrete recycled aggregate and 4% cementitious material, and the external mixing is 9.4% relative to the sum of the above two raw materials Water and an alkali activator with a water mass fraction of 3.5%. Among them, the ratio of the fourth grade of concrete recycled aggregate is 0-4.75mm: 4.75-9.5mm: 9.5-19mm: 19-31.5mm = 32:26:22:20; the cementitious material is composed of slag: cement: gypsum = 60:36:4; the alkali activator is composed of water glass:sodium hydroxide=4:1.

[0049] Base material preparation method: first divide the total water consumption into two parts, add water glass and sodium hydroxide to one part of the water according to the above ratio, and stir the solution with a glass rod until the flake sodium hydroxide is completely dissolved, which is the prepared alkali Activator solution, t...

Embodiment 2

[0051] This embodiment relates to a construction waste pavement base material and a preparation method thereof, the method material is composed of 96% mass fraction of concrete recycled aggregate and 4% cementitious material, and the external mixing is 9.4% relative to the sum of the above two raw materials Water and an alkali activator with a water mass fraction of 4.3%. Among them, the ratio of the fourth grade of concrete recycled aggregate is 0-4.75mm: 4.75-9.5mm: 9.5-19mm: 19-31.5mm = 32:26:22:20; the cementitious material is composed of slag: cement: gypsum = 80:16:4; the alkali activator is composed of water glass:sodium hydroxide=4:1.

[0052] The preparation method of the base material is the same as that of Example 1.

Embodiment 3

[0054] This embodiment relates to a construction waste pavement base material and a preparation method thereof, the method material is composed of 96% mass fraction of concrete recycled aggregate and 4% cementitious material, and the external mixing is 9.4% relative to the sum of the above two raw materials Water and a base activator with a water mass fraction of 5.0%. Among them, the ratio of the fourth grade of concrete recycled aggregate is 0-4.75mm: 4.75-9.5mm: 9.5-19mm: 19-31.5mm = 32:26:22:20; the cementitious material is composed of slag: gypsum = 96: 4; Alkali activator is composed of water glass: sodium hydroxide = 4:1.

[0055] The preparation method of the base material is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com