Non-blending macromolecule concrete and construction method thereof

A construction method and concrete technology, applied in the directions of roads, road repairs, roads, etc., can solve the problems of complicated and troublesome construction techniques, complicated ratios, and inability to construct, and achieve less restrictions on construction techniques, simple construction techniques, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

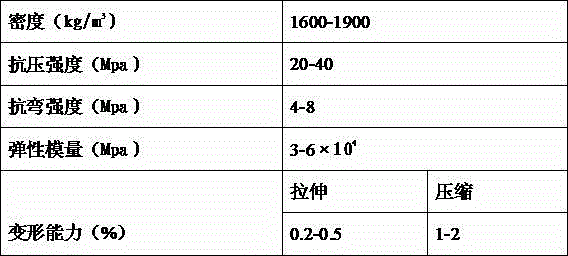

Embodiment 1

[0025] A non-mixing polymer concrete is made of 85kg of aggregate, 12kg of polymer material and 3kg of additives.

[0026] The aggregate is sand and gravel with a material diameter of 0-0.5mm.

[0027] The polymer material described is one-component polyurethane.

[0028] The additive is one or a combination of butyl acrylate, xylylenediamine, ethylenediamine, and polyacrylic acid 。

[0029] The construction method of described non-mixing polymer concrete, this construction method comprises the steps:

[0030] Step 1: Select aggregates with a material diameter of 0-0.5mm according to the place to be used;

[0031] Step 2: Add the aggregate and additives selected in step 1 to the mold or to the set place;

[0032] Step 3: injecting polymer materials into the aggregate in step 2 under a pressure of 4-10 Mpa;

[0033] Step 4: After step 3 is injected into the polymer material, it is cured for 15-25 minutes to complete the construction of the non-mixing polymer concrete.

[...

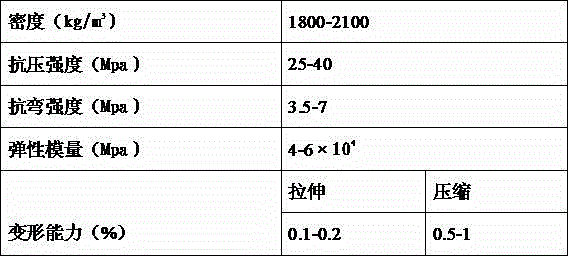

Embodiment 2

[0038] A non-mixing polymer concrete is made of 87kg of aggregate, 10kg of polymer material and 3kg of additives.

[0039] The aggregate is sand and gravel with a material diameter of 0.5mm-3mm.

[0040] The polymer material described is one-component polyurethane.

[0041] The additive is one or a combination of butyl acrylate, xylylenediamine, ethylenediamine, and polyacrylic acid 。

[0042] The construction method of described non-mixing polymer concrete, this construction method comprises the steps:

[0043] Step 1: Select aggregates with a material diameter of 0.5-3mm according to the place to be used;

[0044] Step 2: Add the aggregate and additives selected in step 1 to the mold or to the set place;

[0045] Step 3: injecting polymer materials into the aggregate in step 2 under a pressure of 4-10 Mpa;

[0046] Step 4: Inject step 3 into the polymer material and cure for 15-25 minutes to complete the construction of the non-mixing polymer concrete.

[0047] There i...

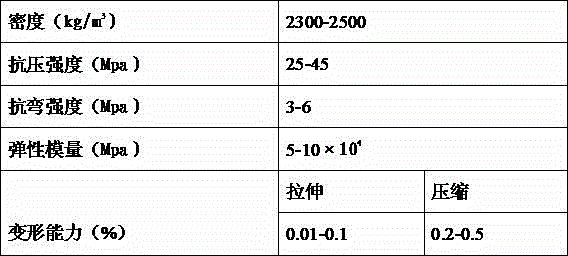

Embodiment 3

[0051] A non-mixing polymer concrete is made of 89kg of aggregate, 8kg of polymer material and 3kg of additives.

[0052] The aggregate is sand and gravel with a material diameter of 3-30mm.

[0053] The polymer material described is one-component polyurethane.

[0054] The additive is one or a combination of butyl acrylate, xylylenediamine, ethylenediamine, and polyacrylic acid 。

[0055] The construction method of described non-mixing polymer concrete, this construction method comprises the steps:

[0056] Step 1: Select aggregates with a material diameter of 0-0.5mm or 0.5-3mm or 3-30mm according to the place to be used;

[0057] Step 2: Add the aggregate and additives selected in step 1 to the mold or to the set place;

[0058] Step 3: injecting polymer materials into the aggregate in step 2 under a pressure of 4-10 Mpa;

[0059] Step 4: Inject step 3 into the polymer material and cure for 15-25 minutes to complete the construction of the non-mixing polymer concrete. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com