Inorganic filling material

A filling material and inorganic technology, applied in the field of inorganic filling materials, can solve the problems of insufficient filling, compactness, and high work intensity in the filling area, and achieve the effects of highlighting explosion-proof and anti-static performance, improving safety conditions, and good airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An inorganic filling material, including material A and material B, the material A is composed of the following parts by mass: bauxite powder 70-80, calcium formate 1-2, alumina 15-20, gypsum 2-5, pulverized coal Ash 15-20, calcium powder 2-5; the B material is composed of the following parts by mass: gypsum 30-40, lime 20-25, composite quick-setting agent 1-2, water reducing agent 0.1-1, expansion agent 1-2 5. Sodium lauryl sulfate 0.1-1, polyolefin 1-5, alkali lignin 0.1-1.

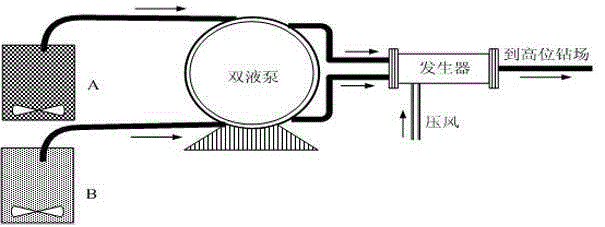

[0012] The construction method of the inorganic refilling material is as follows: two bags of material A and material B are formed into one group. During the construction process, the ratio of material A to material B is 1:1, such as figure 1 As shown, first put material A and material B in two mixing tanks respectively, and mix them at a material-to-water mass ratio of 1:3, and then use a grouting pump to transport the two slurries into the generator, after thorough mixing , transported to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com