Mineral inorganic hole-sealing material and preparing method and using method thereof

A kind of sealing material and inorganic technology, applied in mining equipment, earthwork drilling, sealing/isolation, etc., can solve the problems of severe reaction, inability to seal micro-cracks, and fast reaction speed, so as to reduce the cost of use and labor Strength, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

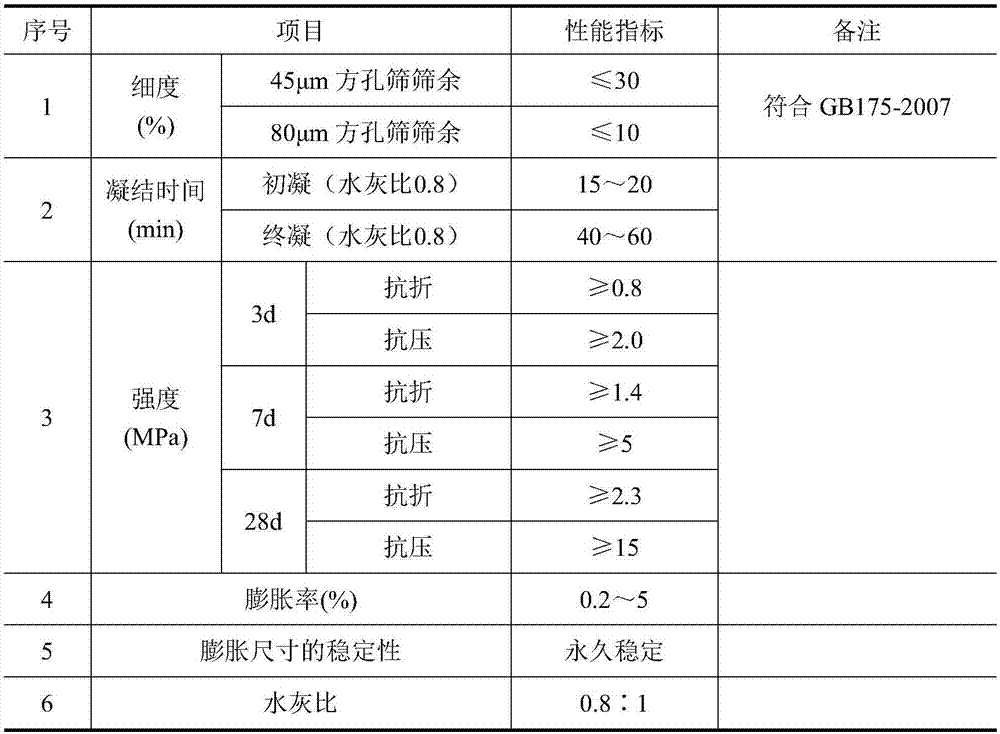

Image

Examples

Embodiment 1

[0025] An inorganic sealing material for mining is composed of the following components in mass percentage: 60% of cement, 12% of fly ash, 6% of alum, 5% of quick-setting agent and 17% of gypsum powder, and the quick-setting agent is aluminum Oxygen clinker, the gypsum powder is secondary gypsum powder, and the cement is ordinary Portland cement.

[0026] The preparation method of the inorganic sealing material for mine described in this embodiment comprises the following steps:

[0027] (1) Prepare raw materials by proportioning, at first cement and gypsum powder are mixed, obtain compound A; Fly ash and alum are mixed, obtain compound B;

[0028] (2) First add 1 / 3 of the mixture A in the mixer, then add 1 / 2 of the mixture B, then add 1 / 3 of the mixture A, then add the quick-setting agent, Finally, add the remaining 1 / 2 of the mixture B and 1 / 3 of the mixture A, fully stir at room temperature, the stirring time is 7min, and the stirring speed is 85r / min;

[0029] (3) After ...

Embodiment 2

[0034] An inorganic sealing material for mining, which is composed of the following components in mass percentage: 50% cement, 30% fly ash, 10% alum, 5% quick-setting agent and 5% gypsum powder, and the quick-setting agent is aluminum Oxygen clinker, the gypsum powder is secondary gypsum powder, and the cement is ordinary Portland cement.

[0035] The preparation method of the inorganic sealing material for mine described in this embodiment comprises the following steps:

[0036] (1) Prepare raw materials by proportioning, at first cement and gypsum powder are mixed, obtain compound A; Fly ash and alum are mixed, obtain compound B;

[0037] (2) First add 1 / 3 of the mixture A in the mixer, then add 1 / 2 of the mixture B, then add 1 / 3 of the mixture A, then add the quick-setting agent, Finally, add the remaining 1 / 2 of the mixture B and 1 / 3 of the mixture A, fully stir at room temperature, the stirring time is 8min, and the stirring speed is 85r / min;

[0038] (3) After the mixi...

Embodiment 3

[0043] An inorganic sealing material for mining is composed of the following components in mass percentage: 87% of cement, 10% of fly ash, 1% of alum, 1% of quick-setting agent and 1% of gypsum powder, and the quick-setting agent is, The gypsum powder is secondary gypsum powder, and the cement is ordinary Portland cement.

[0044] The preparation method of the inorganic sealing material for mine described in this embodiment comprises the following steps:

[0045] (1) Prepare raw materials by proportioning, at first cement and gypsum powder are mixed, obtain compound A; Fly ash and alum are mixed, obtain compound B;

[0046] (2) First add 1 / 3 of the mixture A in the mixer, then add 1 / 2 of the mixture B, then add 1 / 3 of the mixture A, then add the quick-setting agent, Finally, add the remaining 1 / 2 of the mixture B and 1 / 3 of the mixture A, fully stir at room temperature, the stirring time is 7min, and the stirring speed is 90r / min;

[0047] (3) After the mixing is finished, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com