Zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial property as well as preparation method and application thereof

A hydroxyapatite, bioactive technology, applied in coating, metal material coating process, drug delivery, etc., to achieve the effects of high efficiency, promotion of antibacterial activity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial properties, the steps are as follows:

[0034] 1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 800 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0035] 2) Preparation of ZnO coating solution: Zn(CH 3 COO) 2 2H 2 O or Zn(NO 3 ) 2 Provide Zn 2+ source to NaHCO 3 , NaOH or NH 3 ·H 2 O provides OH - source; the OH - The source aqueous solution was added dropwise to Zn 2+ After the source aqueous solution is mixed, the pH value of the mixed solution is finally adjusted to 9 with dilute alkali, and magnetically stirred for 2 hours; wherein, the Zn in the mixed solution 2+ The concentration is 0.43mol / L.

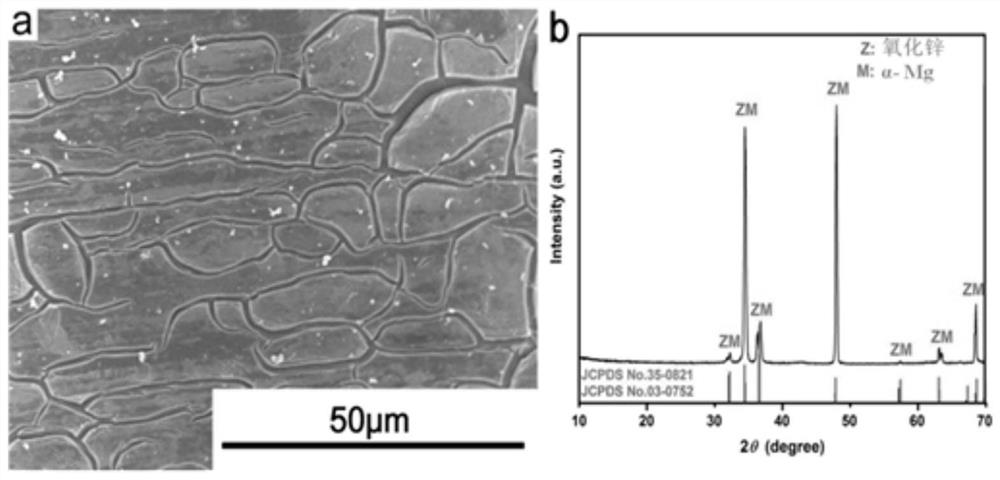

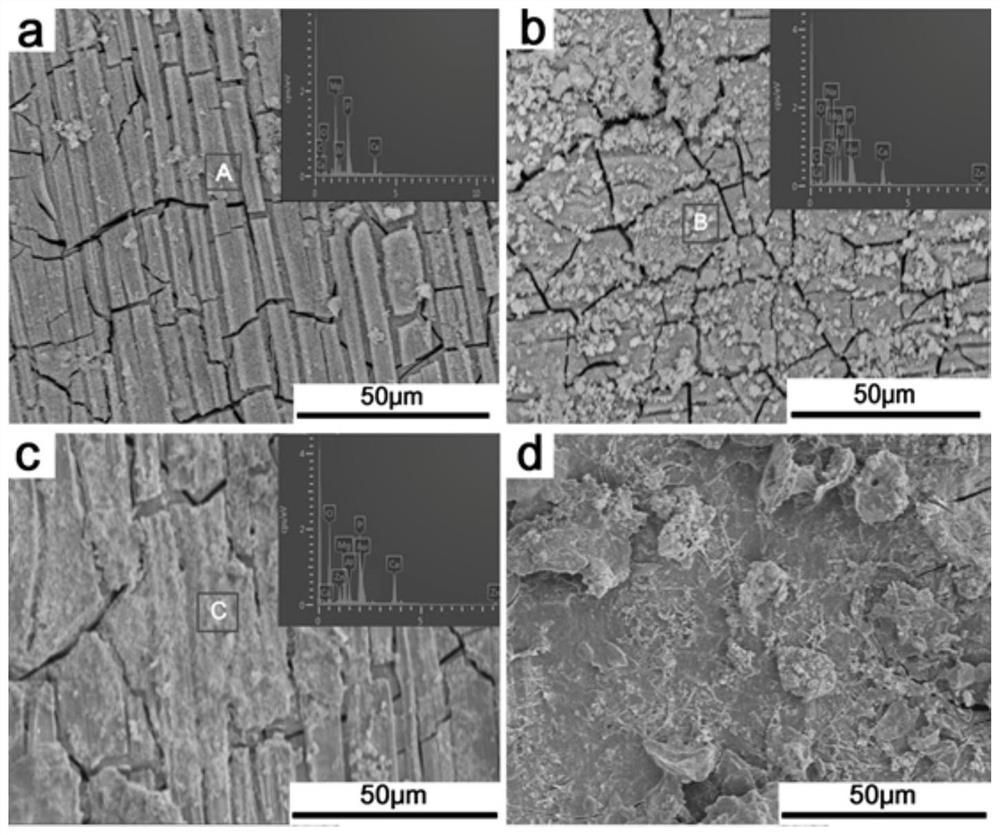

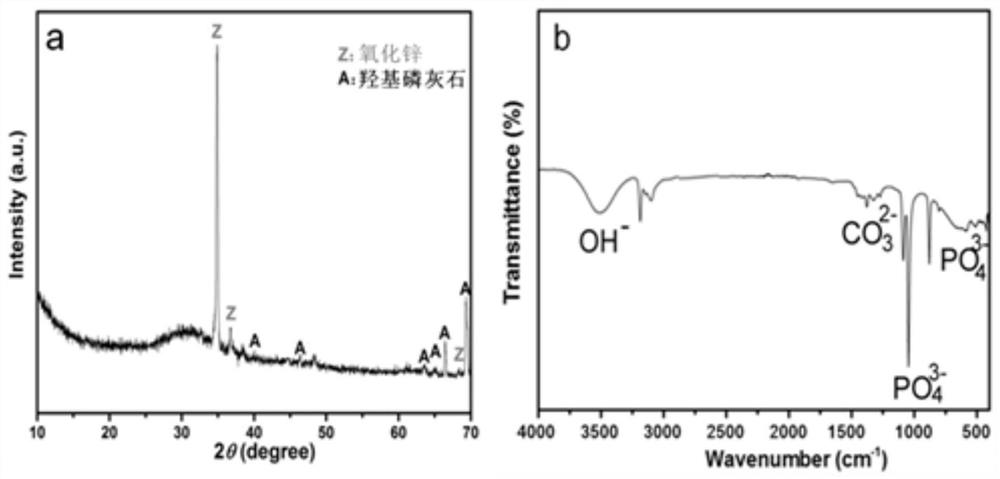

[0036] 3) Preparation of ZnO coating: soak the pretreated magnesium alloy sample in the ZnO coating solution, p...

Embodiment 2

[0042] A method for preparing a zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial properties, the steps are as follows:

[0043] 1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 800 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0044] 2) Preparation of ZnO coating solution: Zn(CH 3 COO) 2 2H 2 O or Zn(NO 3 ) 2 Provide Zn 2+ source to NaHCO 3 , NaOH or NH 3 ·H 2 O provides OH - source; the OH - The source aqueous solution was added dropwise to Zn 2+ After the source aqueous solution is mixed, the pH value of the mixed solution is finally adjusted to 7 with dilute alkali, and magnetically stirred for 2 hours; wherein, Zn in the mixed solution 2+ The concentration is 0.43mol / L.

[0045] 3) Preparation of ZnO coating: soak the pretreated magnesium alloy sample in the ZnO coating solution, place...

Embodiment 3

[0051] A method for preparing a zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial properties, the steps are as follows:

[0052] 1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 800 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0053] 2) Preparation of ZnO coating solution: Zn(CH 3 COO) 2 2H 2 O or Zn(NO 3 ) 2 Provide Zn 2+ source to NaHCO 3 , NaOH or NH 3 ·H 2 O provides OH - source; the OH - The source aqueous solution was added dropwise to Zn 2+ After the source aqueous solution is mixed, the pH value of the mixed solution is finally adjusted to 7 with dilute alkali, and magnetically stirred for 2 hours; wherein, Zn in the mixed solution 2+ The concentration is 0.43mol / L.

[0054] 3) Preparation of ZnO coating: soak the pretreated magnesium alloy sample in the ZnO coating solution, place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com