Surface modifier for regenerated coarse aggregate

A technology of surface modifier and recycled coarse aggregate, which is applied in the field of building materials, can solve the problems of high concrete strength and durability, limited strengthening capacity, and high processing price, so as to improve the surface strength of aggregates and process quickly and conveniently , the effect of improving its own performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Modify sodium silicate: grind sodium silicate solid and sodium hydroxide solid at a mass percentage of 3:1 to make the modulus M 0 Between 1.5-2.0, NaO and SiO in the system 2 The mass percentages of the modified sodium silicate are greater than 4.5% and 9.5% respectively, and its parameters are controlled to meet the requirements of the indicators in Table 1 to obtain modified sodium silicate.

[0024] model

[0025] 2. Preparation of raw materials: slag fine powder is ordinary water-quenched slag; coagulation regulator is sodium fluorosilicate; solid filler is silica fume.

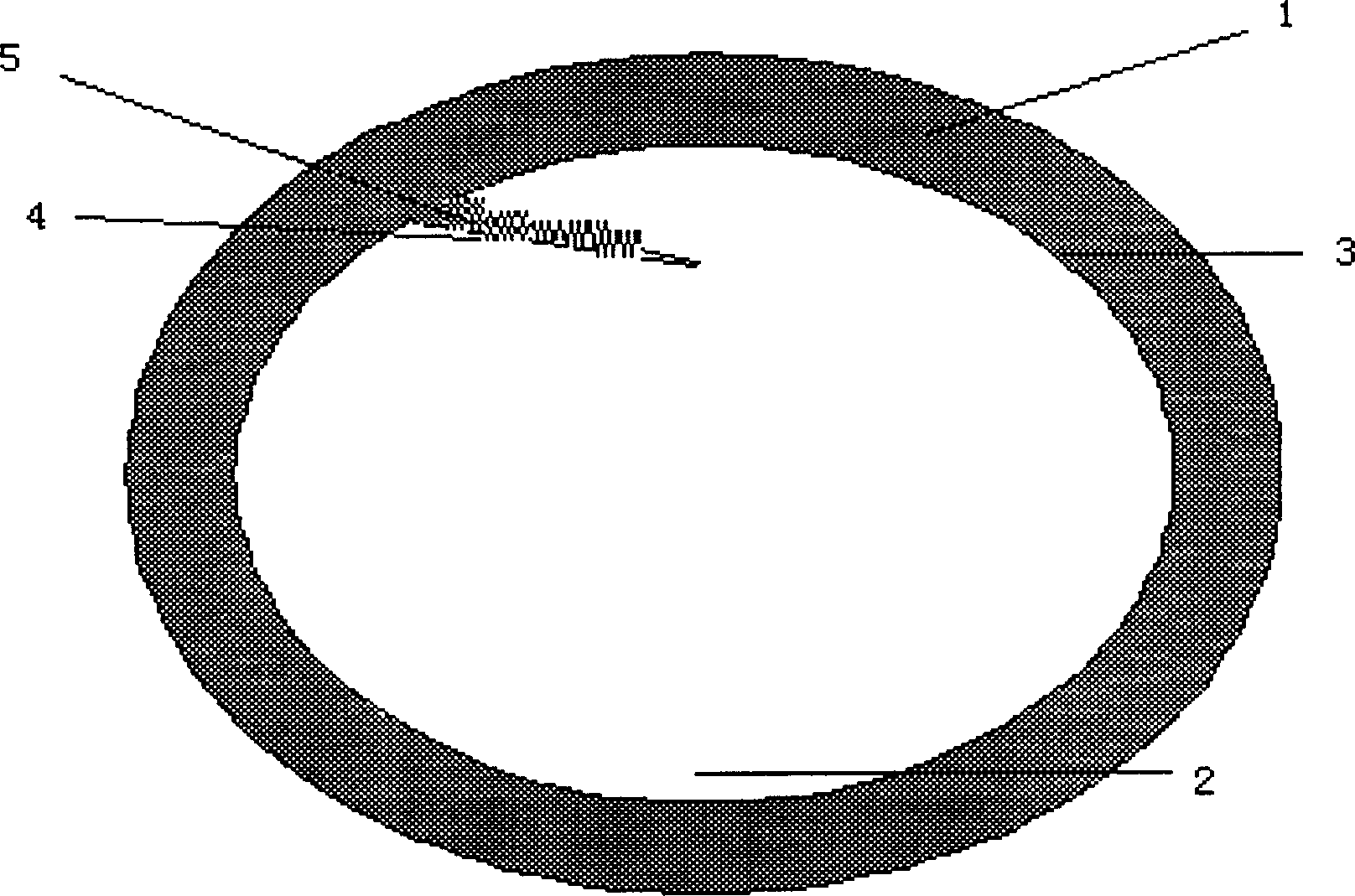

[0026] 3. According to the percentage by weight of each raw material: 84% of slag fine powder, 6% of modified sodium silicate, 1% of coagulation regulator, 9% of solid filler, select raw materials; mix and grind various raw materials to a specific surface area of 1320m 2 / kg to obtain a surface modifier for recycled coarse aggregate. The structure of the recycled coarse aggregate...

Embodiment 2

[0034] 1. Preparation of raw materials: modify sodium silicate: grind sodium silicate solid and sodium hydroxide solid at a mass percentage of 3:1 to make the modulus M 0 Between 1.5-2.0, NaO and SiO in the system 2 The mass percentages are greater than 4.5% and 9.5%, respectively, to obtain modified sodium silicate. The coagulation regulator is sodium fluorosilicate; the solid filler is silica fume.

[0035] 2. According to the weight percentage of each raw material: slag fine powder 80, modified sodium silicate 2, coagulation regulator 0.1, solid filler 17.9, select raw materials; mix and grind various raw materials until the specific surface area is 1000m 2 / kg to obtain a surface modifier for recycled coarse aggregate.

Embodiment 3

[0037]1. Preparation of raw materials: modify sodium silicate: grind sodium silicate solid and sodium hydroxide solid at a mass percentage of 3:1 to make the modulus M 0 Between 1.5-2.0, NaO and SiO in the system 2 The mass percentages are greater than 4.5% and 9.5%, respectively, to obtain modified sodium silicate. The coagulation regulator is sodium fluorosilicate; the solid filler is silica fume.

[0038] 2. According to the weight percentage of each raw material: slag fine powder 90, modified sodium silicate 8, coagulation regulator 1, solid filler 1, select raw materials; mix and grind various raw materials until the specific surface area is 1500m 2 / kg to obtain a surface modifier for recycled coarse aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com