Geopolymer-fiber road pavement mending material and preparation method thereof

A technology for road pavement and repair materials, which is applied in the field of geopolymer-fiber road pavement repair materials and its preparation, can solve the problems of low flexural strength and tensile strength, poor work performance, and easy fiber agglomeration, etc., to achieve Improved flexural and tensile strength, good working performance, and short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of geopolymer-fiber road pavement repairing material, by fly ash 17.43kg, mineral powder 11.62kg, alkali activator solution (the water glass of alkali activator and analytically pure modulus are 1.8) 15.00kg , 0.75kg of water, and 0.125kg of fiber are mixed and prepared. The fiber diameter is 12 μm.

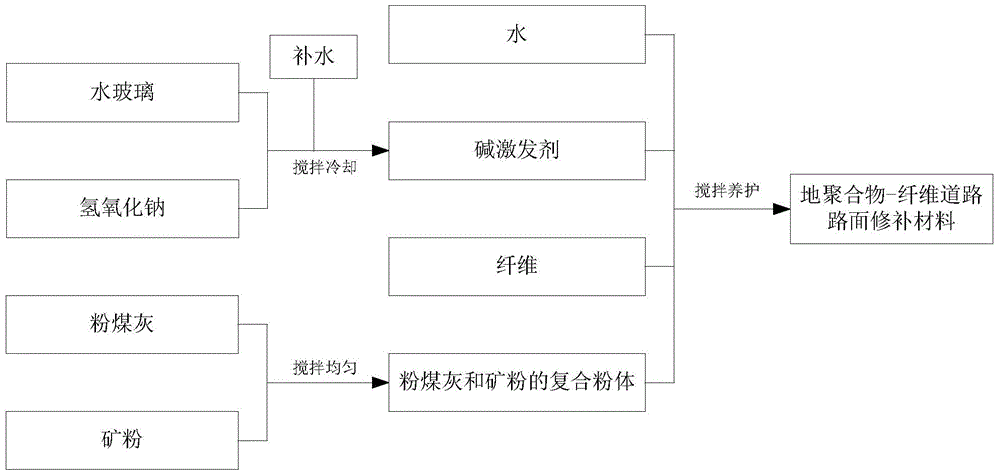

[0029] Such as figure 1 Shown, the preparation steps of above-mentioned geopolymer-fiber road pavement repair material:

[0030] 1) Weigh the fly ash and mineral powder according to the proportioning ratio and preliminarily mix them uniformly to obtain a composite powder of fly ash and mineral powder, which is placed on one side for later use;

[0031] 2) Take water glass and analytical pure (NaOH) according to the proportioning ratio, quickly add the analytical pure to water and stir to cool. High, during the cooling process of the solution, it should be continuously stirred to normal temperature to prepare the alkali activator solution of the requ...

Embodiment 2

[0036] Embodiment 2: a kind of geopolymer-fiber road pavement repairing material, by fly ash 18.06kg, mineral powder 12.04kg, alkali activator solution (the water glass of alkali activator and analytically pure modulus are 1.2) 11.34kg , 3.359kg of water, and 0.125kg of fiber are mixed and prepared.

[0037] The preparation steps of the above-mentioned geopolymer-fiber road pavement repair material are the same as those in Example 1.

[0038] The test performance results are as follows:

[0039] Fluidity: 235mm Initial setting time: 137min Final setting time: 182min

[0040] Pilot projects

Embodiment 3

[0041] Embodiment 3: a kind of geopolymer-fiber road pavement repairing material, by fly ash 18.06kg, mineral powder 12.04kg, alkali activator solution (the water glass of alkali activator and analytically pure modulus are 1.2) 11.34kg , 3.359kg of water, and 0.25kg of fiber are mixed and prepared.

[0042] The preparation steps of the above-mentioned geopolymer-fiber road pavement repair material are the same as those in Example 1.

[0043] The test performance results are as follows:

[0044] Fluidity: 235mm Initial setting time: 137min Final setting time: 182min

[0045] Pilot projects

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com