Method for preparing ceramic/iron-based amorphous composite coating

An iron-based amorphous and composite coating technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of uncontrollable ratio of amorphous and ceramic in the coating, large performance fluctuations, etc. Achieve high hardness and wear resistance, wide composition range, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

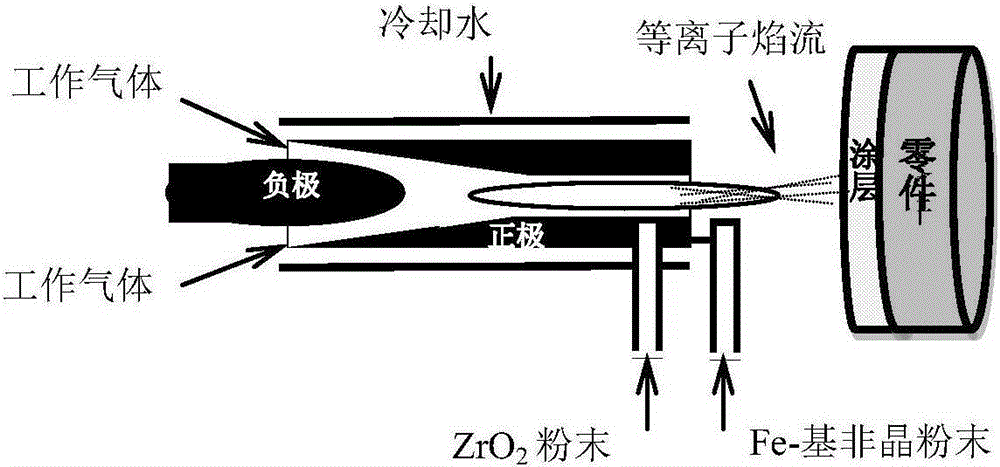

Method used

Image

Examples

Embodiment 1

[0025] Example 1: The substrate is made of 45# steel, Fe-based amorphous and ZrO in the composite coating 2 The mass ratio of ceramics is 4:1 as an example.

[0026] The embodiments of the present invention adopt the following technical conditions:

[0027] 1. Before spraying, clean the surface of the alloy workpiece such as rust, scale, and oil, and dry it for later use;

[0028] 2. The pretreated alloy workpiece is subjected to sandblasting coarsening activation treatment; the purpose is to remove impurities such as oil stains on the surface of the substrate, improve the roughness of the substrate, and help the coating and the substrate produce good mechanical occlusion, and increase the coating and The bonding area between the substrates, so as to achieve the purpose of improving the bonding strength between the coating and the substrate;

[0029] 3. In order to increase the bonding strength between the coating and the substrate, the alloy workpiece that has been sandblasted and co...

Embodiment 2-3

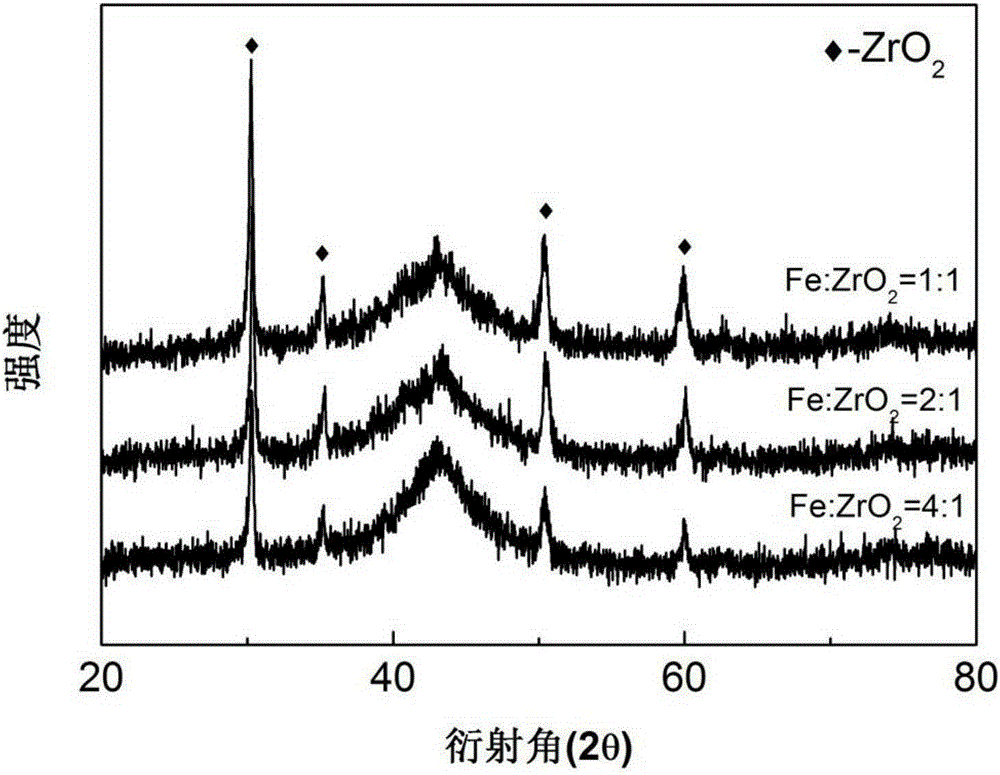

[0035] Example 2-3: The substrate is made of 45# steel, Fe-based amorphous and ZrO in the composite coating 2 The mass ratio of the ceramic was changed from 4:1 to 2:1 and 1:1 respectively; the other steps were the same as in Example 1.

[0036] The composite coating prepared by the plasma double powder feeding technology in the present invention can not only control the amorphous phase structure to avoid the influence of the addition of the ceramic crystal phase on the amorphous forming ability, but also realize the controllable composition ratio. The ratio of the two phases in the composite coating is changed by adjusting the flow rate of the powder feeding gas. Fe-based amorphous and ZrO 2 When the mass ratio of ceramics is 4:1, 2:1 and 1:1, the powder feeding air flow of Fe-based amorphous powder is 74L / min, 37L / min and 18L / min, respectively, and the spray gun distance is 86mm, 92mm and 100mm.

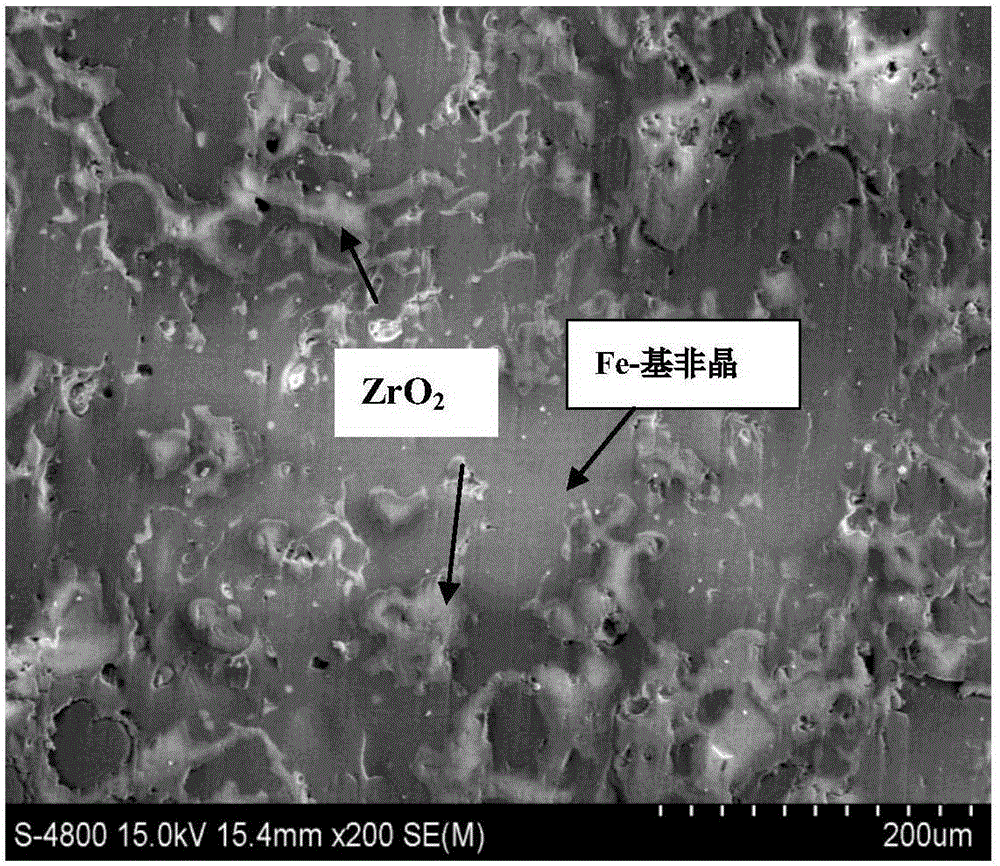

[0037] Fe-based amorphous and ZrO 2 The XRD diffraction spectra of composite coati...

Embodiment 4

[0039] Example 4: The substrate is made of 45# steel, Fe-based amorphous and Al in the composite coating 2 O 3 The mass ratio of ceramics is 4:1 as an example. The other steps are the same as in Example 1, except that the ceramic powder is made of ZrO 2 Change to Al 2 O 3 . Spraying process Al 2 O 3 The ceramic powder is fed inside the gun, and the Fe-based amorphous powder is fed outside the gun. The powder feeding distance is 12mm from the nozzle. Said plasma spraying technology: spraying power is 32Kw, current is 500A, voltage is 64V, spraying distance between spray gun and workpiece is 90mm, spray gun moving speed is 6-8m / min, H 2 The gas flow rate is 120L / min, the powder feeding gas for amorphous powder and ceramic powder is Ar gas, Al 2 O 3 The gas flow rate of ceramic powder is 20L / min. The density of Fe-based amorphous phase is 7.0g / cm 3 , Al 2 O 3 The density of the ceramic phase is 4.2g / cm 3 , The powder feeding gas flow rate of Fe-based amorphous powder is 48L / min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com