One-step neutralization and activation production process containing humic acid diammonium phosphate

A humic acid diammonium phosphate and production process technology, which is applied in ammonium salt fertilizer, nitrogen fertilizer, agriculture, etc., can solve problems such as inability to improve phosphorus utilization rate, production process obstacles, production environment impact, etc., and achieve crystallization blocking problems, no The difference between batch head and batch end, the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) The influence of moisture content.

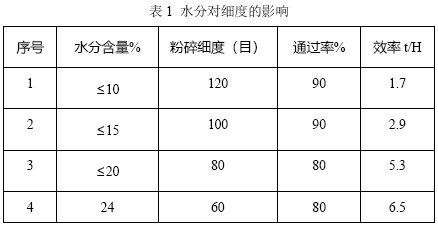

[0052] The weathered pulverized coal with a moisture content of 9.7%, 14.6% and 19.4% was selected for the Raymond mill pulverization test. The selected Raymond mill spindle motor was 30kw / H and the fan was 20kw / H. The working efficiency of different moisture content is shown in the table below.

[0053]

[0054] It can be seen from the table that the lower the moisture content, the higher the product fineness, but the lower the yield.

[0055] (2) The influence of fineness.

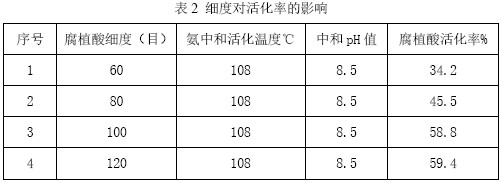

[0056] The dry base of humic acid powder (52%) and the wet process phosphoric acid (25% P) of different fineness were selected respectively. 2 O 5 ) are mixed in proportion to neutralize ammonia, and the humic acid activation rate in the obtained humic acid diammonium phosphate is shown in the following table.

[0057]

[0058] It can be seen from the table that the activation rate of humic acid increases with the increase of the fineness of humic...

Embodiment 2

[0060] (1) Production of humic acid mineral powder.

[0061] The weathered coal with a humic acid content (dry basis) of 52% is selected for primary grinding to 20 mesh, dried to a moisture content of 25%, and then subjected to Raymond mill for secondary grinding, so that the powder fineness reaches 60 mesh.

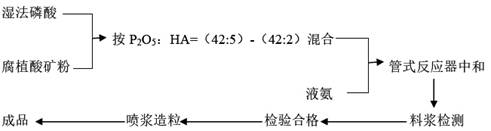

[0062] (2) Production of humic acid-containing diammonium phosphate.

[0063] P at room temperature 2 O 5 Mixed with 25% wet-process phosphoric acid and humic acid mineral powder (HA), P 2 O 5 : HA (dry basis) = (42:3), that is, 168 parts of 25% phosphoric acid and 3.95 parts of 60 mesh humic acid powder with 25% water content are dispersed and mixed in the feed tank, and then pumped to the tubular reactor, The ammonia gas after gasification with liquid ammonia enters the tubular reactor for neutralization and concentration under the action of the compressor, and the MRC of the neutralization degree is controlled at 1.83; %, nitrogen content 15.1%, P 2 O 5 Contain...

Embodiment 3

[0066] (1) Production of humic acid mineral powder.

[0067] The weathered coal with a humic acid content (dry basis) of 52% was selected for primary grinding to 20 mesh, dried to a moisture content of 20%, and then subjected to Raymond mill for secondary grinding, so that the powder fineness reached 80 mesh.

[0068] (2) Production of humic acid-containing diammonium phosphate.

[0069] P at room temperature 2 O 5 Mixed with 25% wet-process phosphoric acid and humic acid mineral powder (HA), P 2 O 5 : HA (dry basis) = (42:3), that is, 168 parts of 25% phosphoric acid and 3.72 parts of 80 mesh humic acid powder with a water content of 20% are dispersed and mixed in the feed tank, and then pumped to the tubular reactor, The ammonia gas after gasification with liquid ammonia enters the tubular reactor for neutralization and concentration under the action of the compressor, and the MRC of the neutralization degree is controlled at 1.83; %, nitrogen content 15.3%, P 2 O 5 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com