Flexible display panel, display device and flexible display panel manufacturing method

A technology of flexible display and manufacturing method, which is applied in the directions of identification device, final product manufacturing, climate sustainability, etc., and can solve problems such as display failure and inorganic insulating layer cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

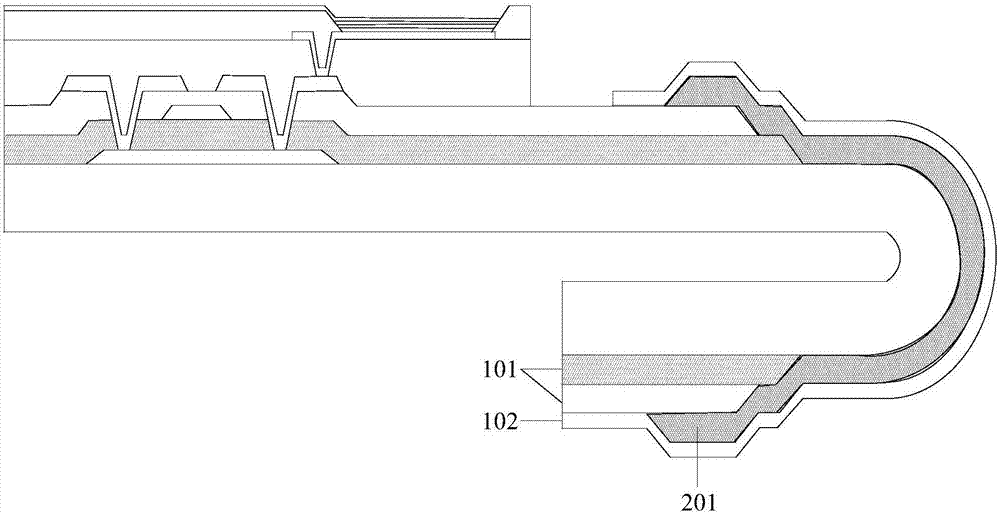

[0048] A flexible display panel provided by Embodiment 1 of the present invention, such as image 3 As shown, it includes: a flexible substrate substrate 301, a conductive layer 302 disposed on the display area A of the flexible substrate substrate, a plurality of wires 303 disposed on the edge bending region B of the flexible substrate substrate, and a plurality of wires 303 disposed on the conductive layer 302 and The inorganic insulating layer 304 between the multiple wiring lines 303 and the flexible substrate 301; the conductive layer 302 is electrically connected to the multiple wiring lines 303 and arranged on the same layer; in particular, the flexible display panel also includes:

[0049] At least the first organic insulating layer 305 is disposed on the edge bending area B of the flexible substrate; the first organic insulating layer 305 is located between the plurality of wires 303 and the inorganic insulating layer 304, and the material of the first organic insulati...

Embodiment 2

[0055] Since the structure of the flexible display panel provided by Embodiment 2 of the present invention is similar to that of the flexible display panel provided by Embodiment 1 of the present invention, only the flexible display panel provided by Embodiment 2 of the present invention and the flexible display panel provided by Embodiment 1 of the present invention are discussed here. The differences will be introduced, and the repetitions will not be repeated.

[0056] According to the above description, in the flexible display panel provided in Embodiment 1 of the present invention, the inorganic insulating layer 304 has a via hole pattern. In practical applications, the conductive layer 302 located at the via hole pattern may be broken, which affects the display effect of the flexible display panel.

[0057] Specifically, in order to prevent the conductive layer 302 from breaking at the via hole pattern, in the above flexible display panel provided in Embodiment 2 of the ...

Embodiment 3

[0060] Since the structure of the flexible display panel provided by the third embodiment of the present invention is similar to that of the flexible display panel provided by the second embodiment of the present invention, only the flexible display panel provided by the third embodiment of the present invention is compared with the flexible display panel provided by the second embodiment of the present invention. The differences will be introduced, and the repetitions will not be repeated.

[0061] Specifically, on the basis of the flexible display panel provided in the second embodiment of the present invention, in order to prevent the multiple traces 303 in the bending area B at the edge of the flexible substrate from being scratched, the above flexible display panel provided in the third embodiment of the present invention display panel, such as Figure 5 As shown, the second organic insulating layer 310 disposed at least at the edge bending area B of the flexible substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com