Rolling controlling method and device for double-roller continuous casting magnesium alloy sheet

A magnesium alloy, continuous casting technology, applied in metal rolling, rolling force/roll gap control, temperature control, etc., can solve the problems of improving uniformity, not mentioned, etc., to reduce anisotropy, improve strength, Effect of suppressing the tendency of rolling cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

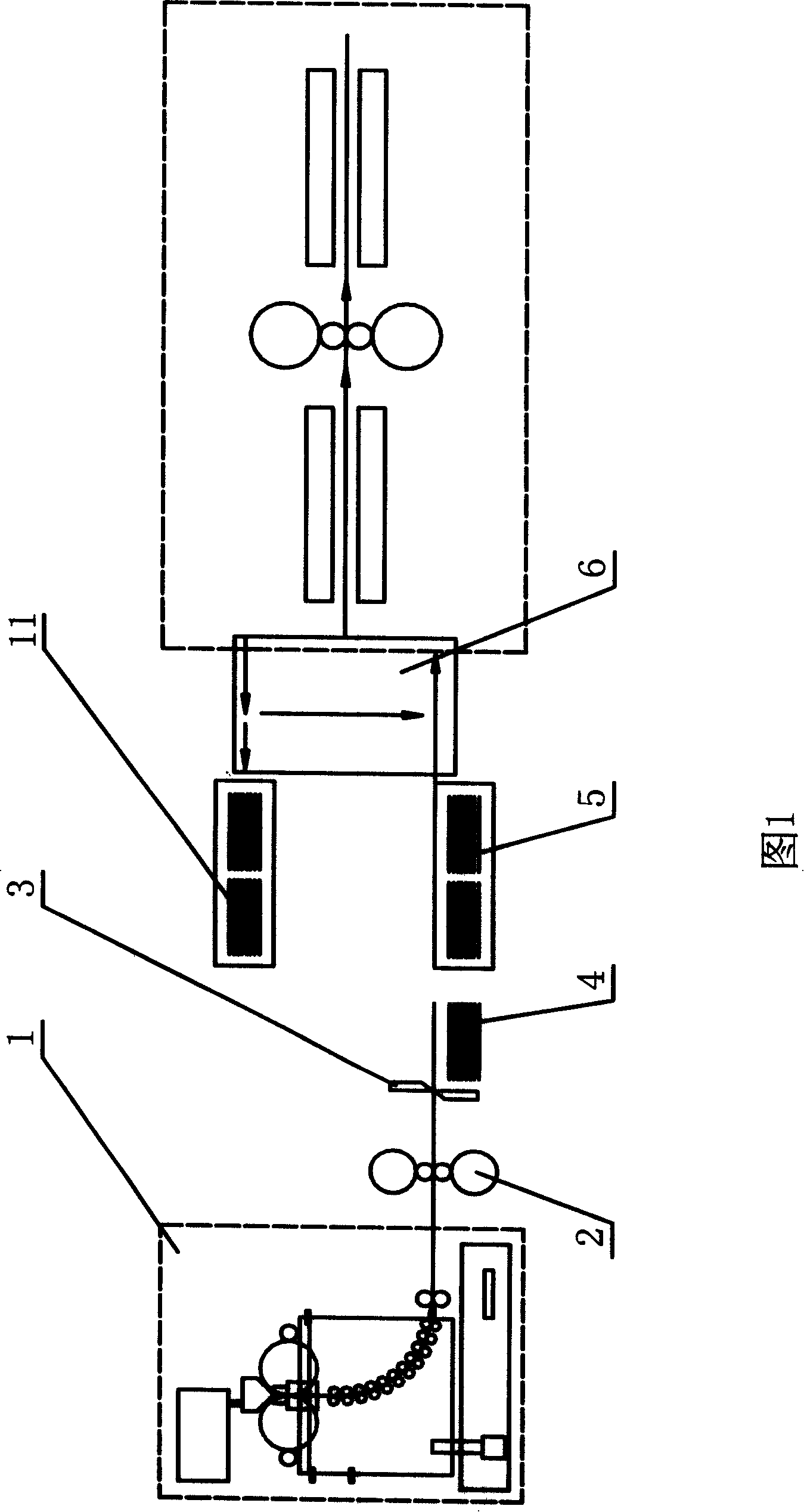

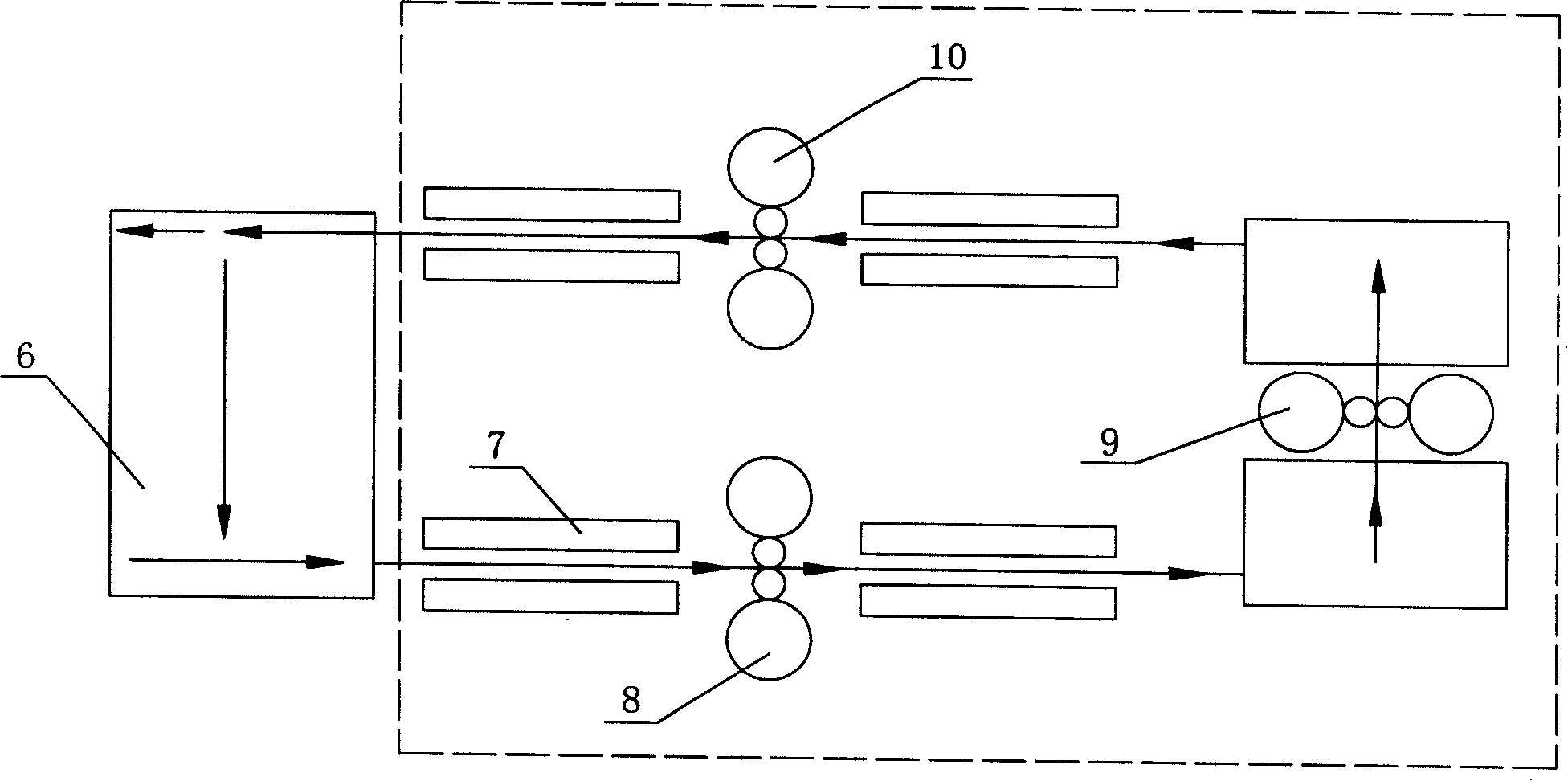

[0026] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0027] a. The molten magnesium alloy solution is cast-rolled in an integrated casting-rolling machine 1 . Taking AZ31 magnesium alloy as an example, the liquid metal casting temperature is controlled at 680-720°C; the temperature of the casting rolls of the cast plate is 350-450°C, the casting and rolling speed is 15-20m / min, and the thickness of the plate is 2.5-3mm; Enter the lower cooling system, control the cooling speed and prevent high-temperature oxidation in the cooling oil, run the oil outlet groove along the guide roller group, and control the temperature of the cast plate oil outlet groove at 300-350°C. Use squeeze rolls to remove excess oil from the surface of the casting rolls.

[0028] b. The cast plate out of the oil tank is leveled and lightly rolled by a rolling mill 2, then cut by flying shear 3, collected on a stand 4 and stacked, and then e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com