Method for preparing porous super fine calcium carbonate

An ultra-fine calcium carbonate and porous technology, applied in the field of calcium carbonate, can solve the problems of easily polluted environment, large power consumption, and no recycling of ammonium chloride, and achieves enhanced heat transfer, power saving, and flexible selection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

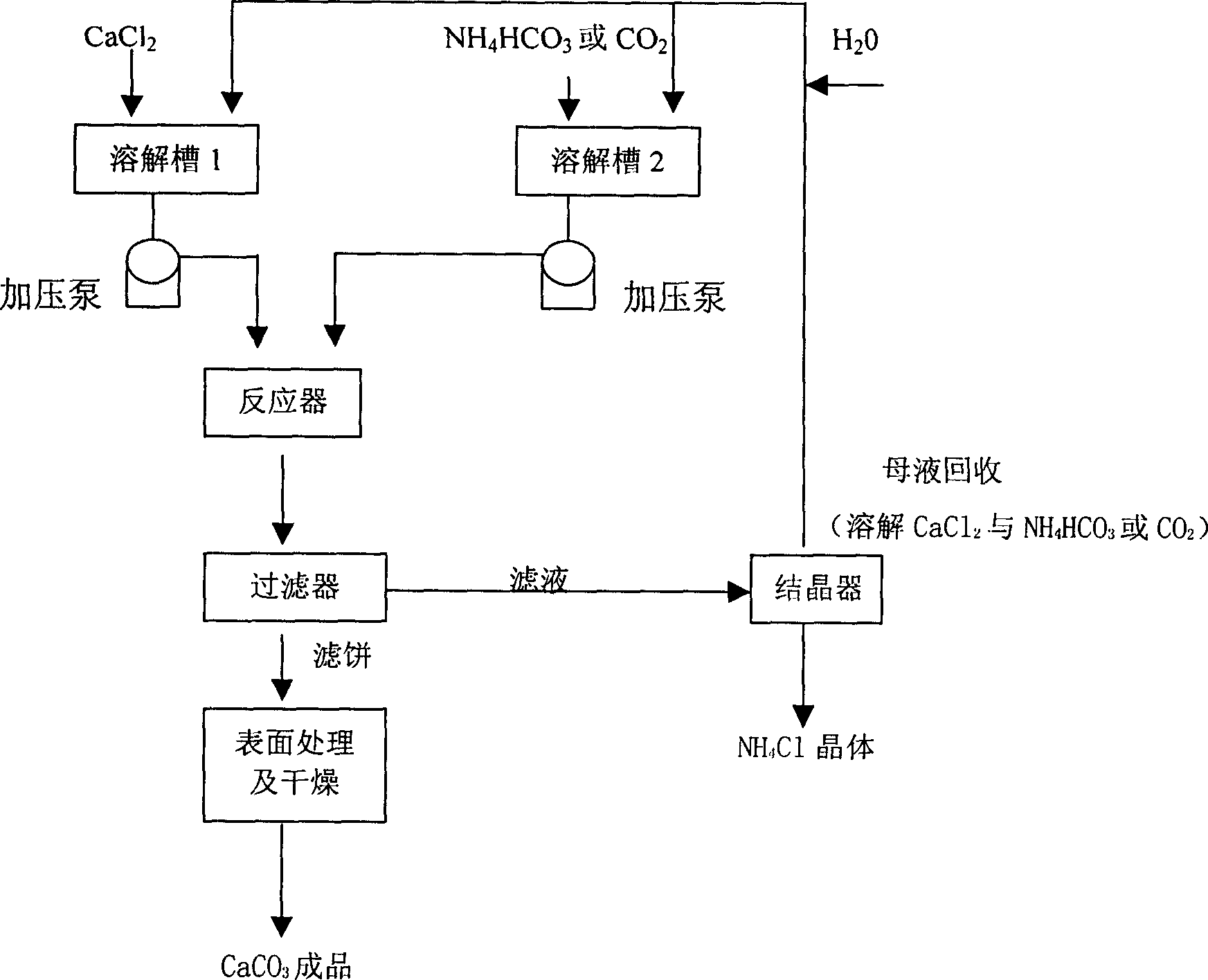

Image

Examples

preparation Embodiment 1

[0019] equipment:

[0020] Stirrer model: RW20.n Power: 70W

[0021] Manufacturer: Guangzhou IKA Co., Ltd.

[0022] Vacuum pump model: SHZ-IIIB Working voltage: 220V Power: 180W Pumping speed (single tube / double tube): 10 / 20L / min

[0023] Manufacturer: Zhejiang Linhai Jinggong Vacuum Equipment Factory

[0024] Circulation pump model: DP-125 Flow rate: 1L / min Working voltage: 220V

[0025] Working current: 1.3A Manufacturer: Xishan Water Pump Factory

[0026] Flowmeter model: LZB-10 glass rotameter Flow range: 6-60L / h

[0027] Manufacturer: Yuyao Yinhuan Flow Meter Co., Ltd.

[0028] Weigh 110gCaCl 2 with 158g NH 4 HCO 3 were prepared into 1000ml aqueous solution, and in NH 4 HCO 3 Add 0.002molH to the aqueous solution 2 SO 4 , colliding reaction in impinging flow reactor, flow rate 0.6L / min, reaction temperature 20°C. The reaction solution was filtered, and the filter cake was dried and ground. get 100gCaCO 3 , and its SEM photo after magnification of 200...

Embodiment 2

[0030] Medicines and equipment are the same as in Example 1.

[0031] Weigh 110gCaCl 2 with 158g NH 4 HCO 3 were prepared into 1000ml aqueous solution, and in NH 4 HCO 3 Add 0.004 mol MgCl2 to the aqueous solution, and react in an impingement flow reactor with a flow rate of 0.6 L / min and a reaction temperature of 20°C. The reaction solution was filtered, and the filter cake was dried and ground. get 100gCaCO 3 , and its SEM photo after magnification of 30000 times is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com