Vibration crushing device for construction waste resource recovering

A construction waste and crushing device technology, applied in grain processing, construction waste recycling, recycling technology and other directions, can solve the problems of poor crushing treatment effect of construction waste, single structure design, reduced work efficiency, etc., and achieve good crushing treatment effect, Simple and convenient operation, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

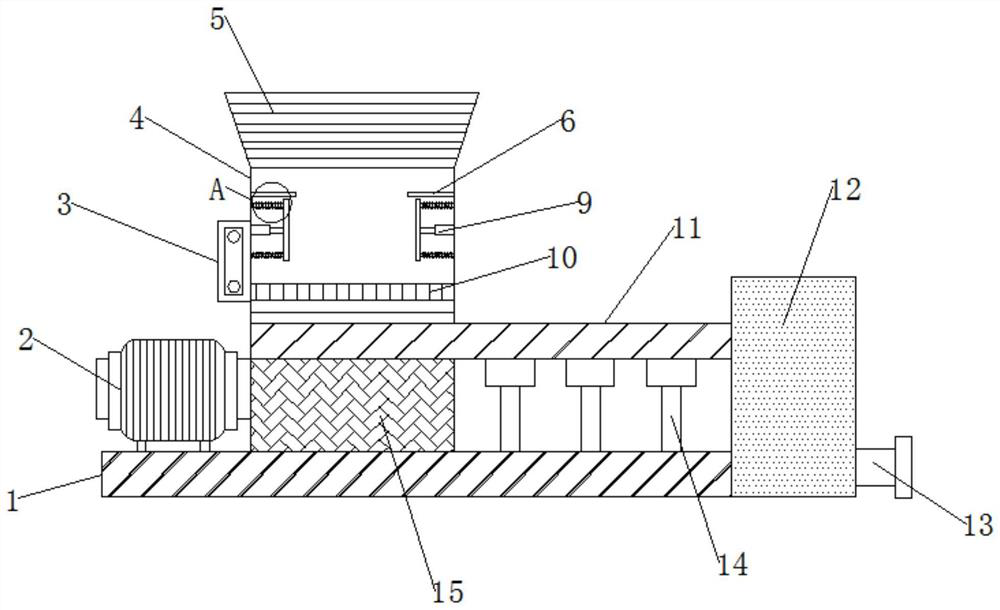

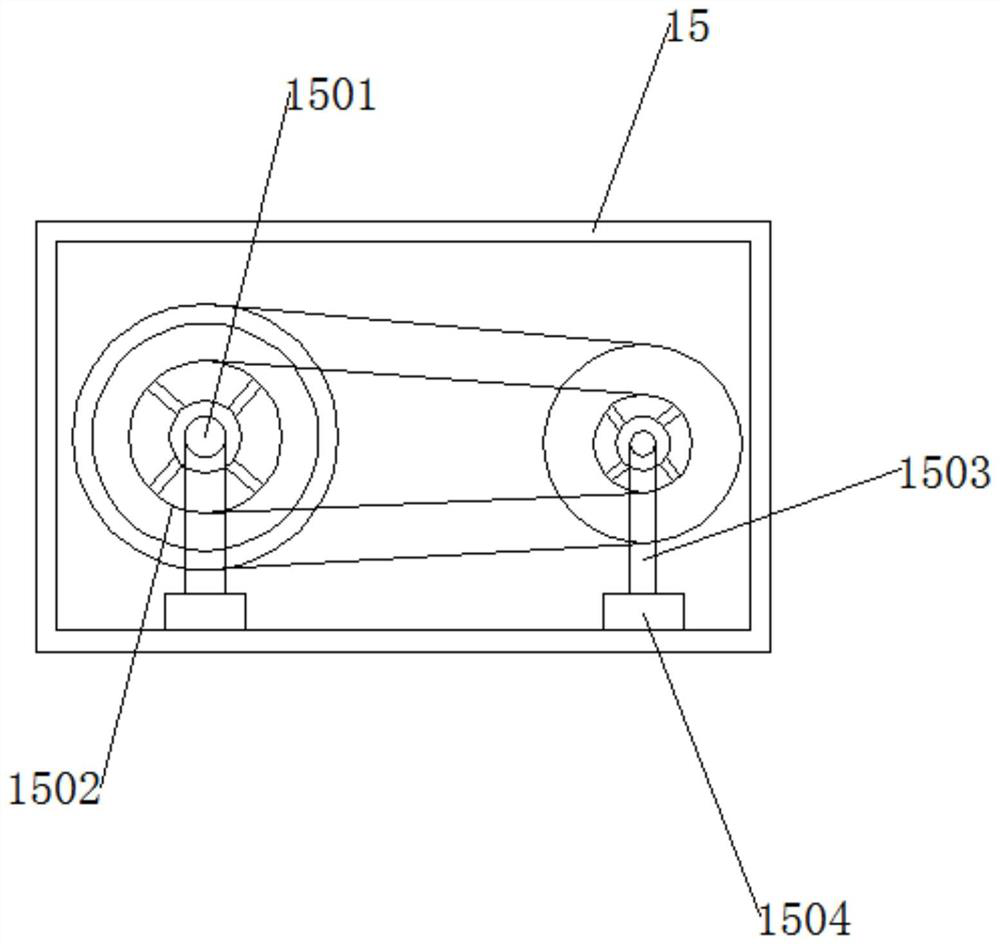

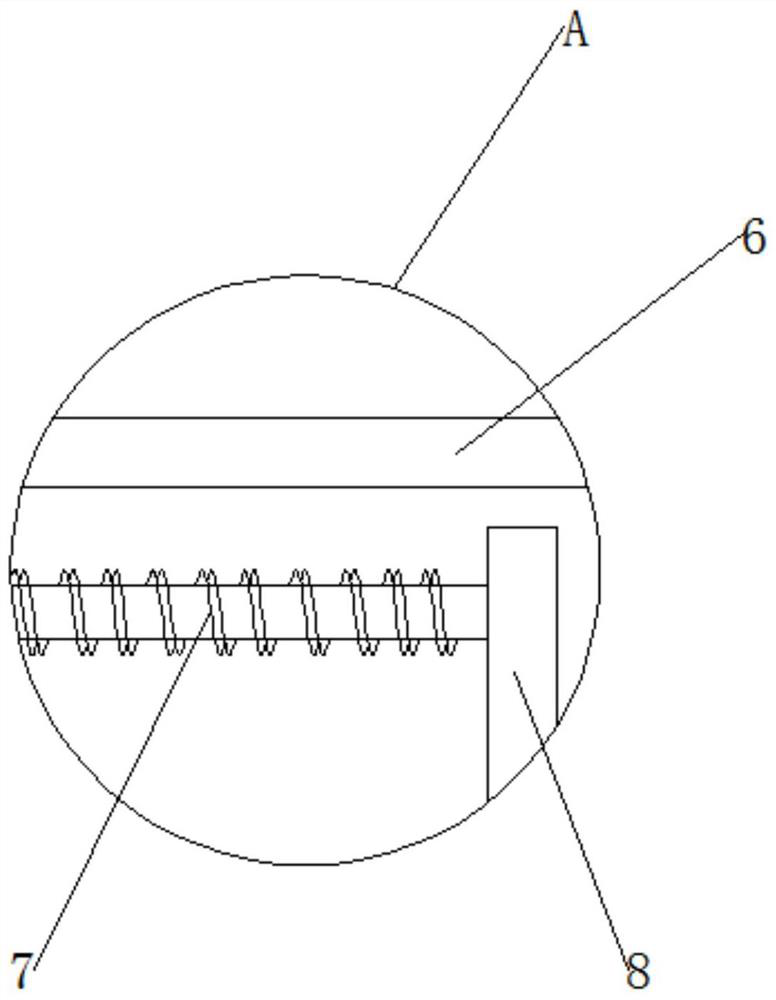

[0025] refer to Figure 1-4 ,

[0026] A vibration crushing device for recycling construction waste provided in this embodiment includes a base plate 1, a motor 2 and a vibration crusher 4, and is characterized in that the motor 2 is located on the left side of the upper end of the base plate 1, and the motor 2 is fixed to the base plate 1 connection, the right side of the motor 2 is provided with a vibrating crusher 4, and the vibrating crusher 4 is fixedly connected with the bottom plate 1, and the upper end of the external left side of the vibrating crusher 4 is provided with a control switch 3, and the control switch 3 is fixed with the vibrating crusher 4 connected, the upper end of the vibratory crusher 4 is provided with a garbage dump inlet 5, and the garbage dump inlet 5 is fixedly connected with the vibratory crusher 4, and the inner upper end of the vibratory crusher 4 is provided with a fixed baffle 6, and the fixed baffle 6 is all connected to the vibratory crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com