Pig feed crushing and drying integrated processing equipment

A technology for processing equipment and pig feed, applied in feed, grain processing, food science, etc., can solve the problems of reducing the scope of application of pig feed, limited effect of crushing, and reducing the practicability of equipment, so as to improve the effect of crushing and improve the practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

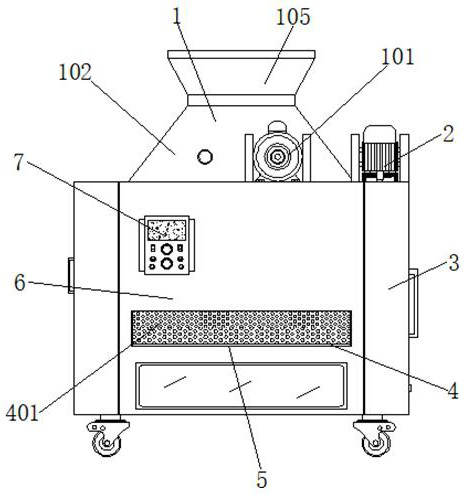

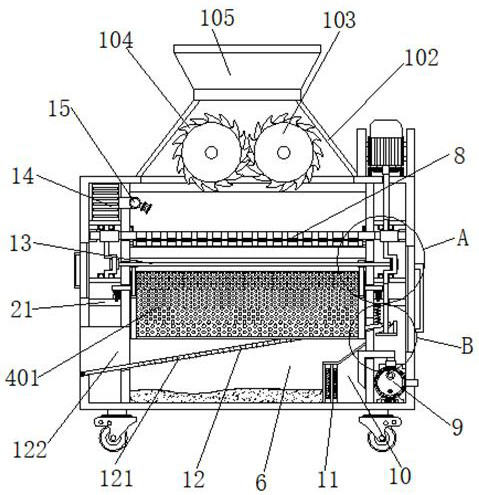

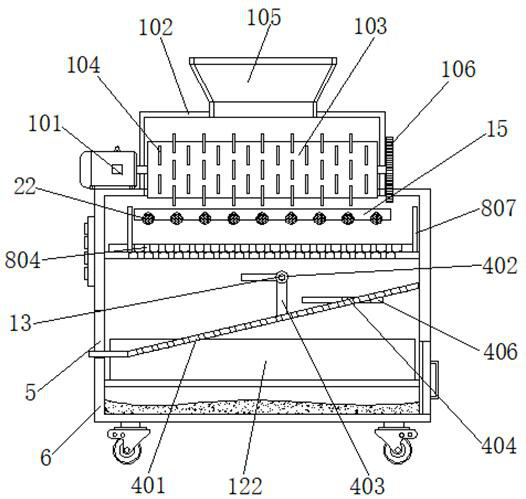

[0038] Example 1, such as Figure 1-3 As shown, when the pig feed raw material needs to be pulverized in the first step, the control panel 7 controls the servo motor 101 and the drive motor 2 to start rotating, and the servo motor 101 drives a group of guide rollers 103 to rotate, and the transmission of the gear 106 can make Two sets of guide rollers 103 rotate oppositely, and then the pig feed material is put into the inside of the crushing bin 102 from the top of the discharge hopper 105, and the pig feed material is cut and crushed after passing through multiple sets of crushing blades 104 on the outside of the guide roller 103, and the pig feed material after crushing The feed material falls to the top of the upper deck 804 .

Embodiment 2

[0039] Example 2, such as Figure 2-7 As shown, when the pig feed material needs to be chopped in the second step, the drive motor 2 is turned on to drive the crankshaft 16 to rotate, and the crankshaft 16 cooperates with the square channel 805 to force the upper plate 804 to move horizontally back and forth, and the spring A807 inside the chute 806 is constantly After shrinking, it is elongated, so that the blanking holes 803 on the upper plate 804 and the lower plate 801 are continuously overlapped and then staggered. The falling pig feed is shredded for the second time.

Embodiment 3

[0040] Example 3, such as Figure 1-7 As shown, when the crushed pig feed needs to be screened, the drive motor 2 is turned on to drive the crankshaft 16 to rotate, and the crankshaft 16 cooperates with the bearing A17 to force the connecting rod 13 to swing back and forth horizontally. From a top view, the connecting rod 13 is elliptical The collar 402 slides on the outside of the connecting rod 13, thereby driving the sieve plate 401 to make a horizontal movement back and forth. During the process, the collar 402 slides on the outside of the connecting rod 13, and the movable plate 404 moves back and forth inside the limiting groove A406 sliding, and the roller 405 rolls back and forth on the top of the mounting plate 21, and the crankshaft 16 forces the end of the secondary sieve plate 121 close to the arc-shaped protrusion 126 to swing up and down through the cooperation of the connecting shaft 125 and the arc-shaped protrusion 126, and the spring B124 keeps Shrink and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com