Coal briquette rapid crushing device

A crushing device and fast technology, applied in grain processing and other directions, can solve the problems of poor crushing effect, inability to achieve rapid crushing of coal, insufficient refinement of coal, etc., to achieve rapid crushing effect, promote sufficient crushing effect, Improves the effect of shattered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

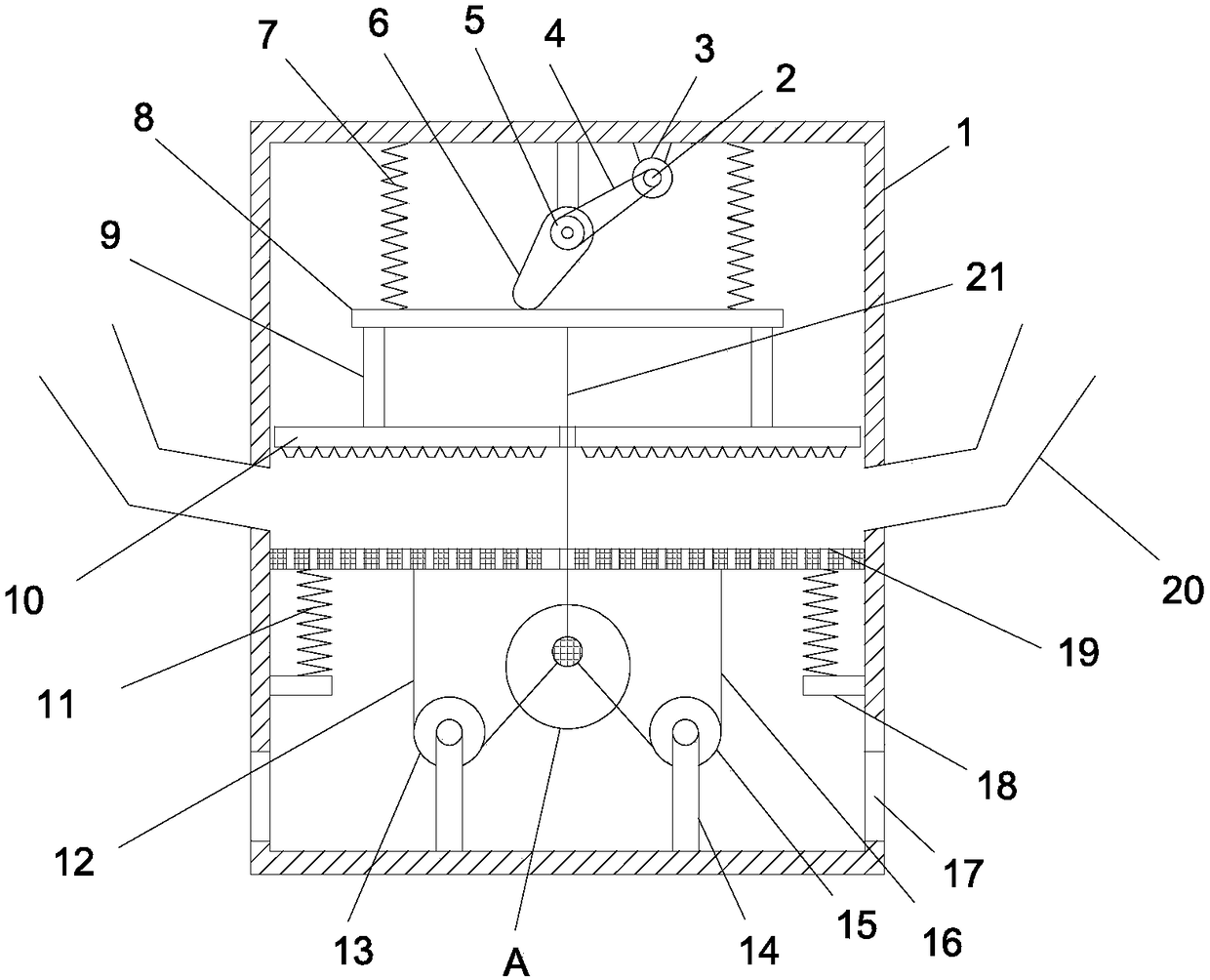

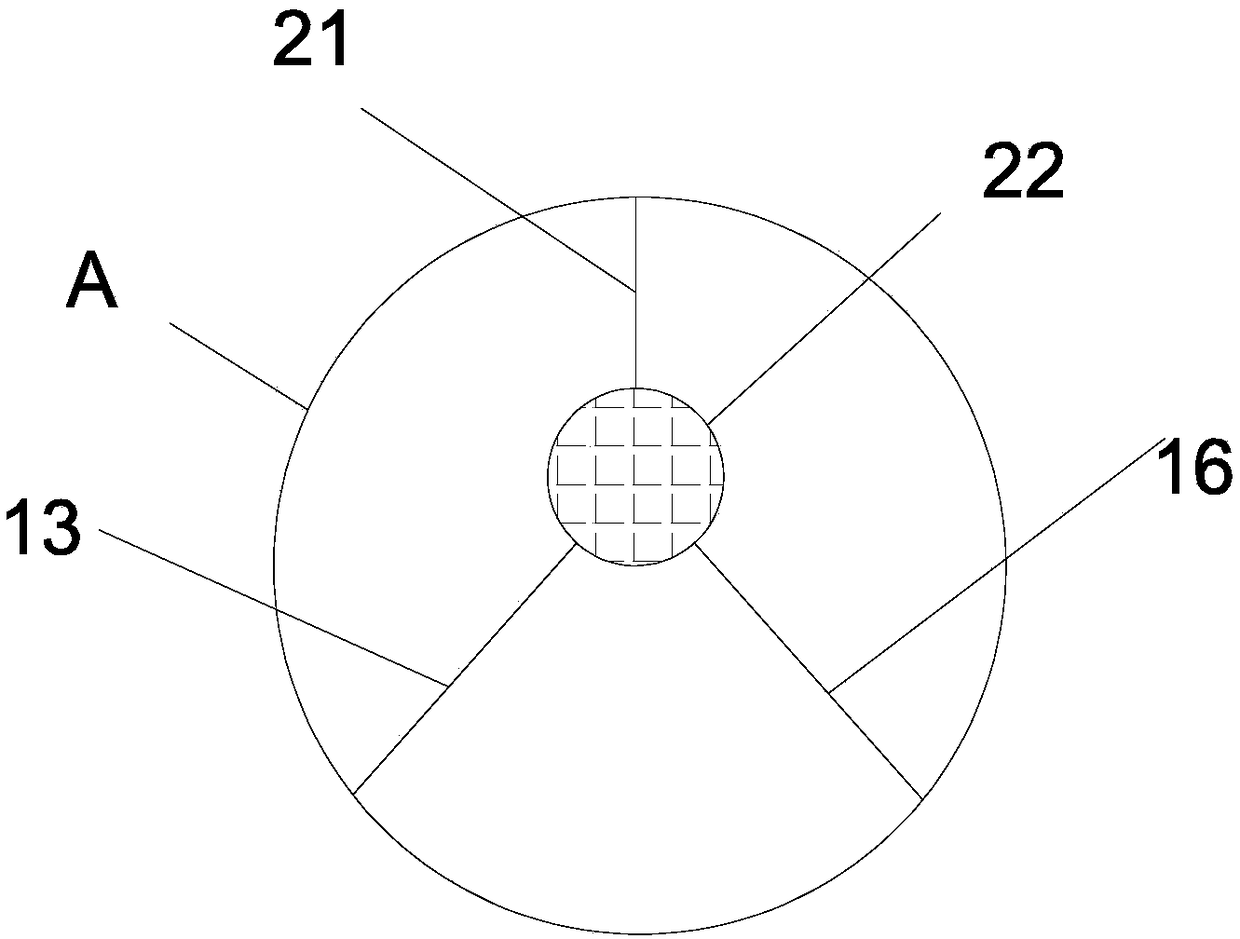

[0019] see Figure 1-2 , a coal block quick crushing device, comprising a body 1, two feed pipes 20 communicated with the interior of the body 1 are symmetrically opened on the left and right side walls of the body 1, and two outlet pipes 20 communicated with the interior of the body 1 are symmetrically opened on the lower side wall of the body 1 The feed port 17, the drive motor 3 is fixedly installed on the inner top of the body 1, the output shaft of the drive motor 3 is fixedly installed with the driving pulley 2, the top of the body 1 is rotatably hung with a cam 6, and the front of the cam 6 is coaxial The driven pulley 5 is fixedly installed, and the driven pulley 5 and the driving pulley 2 are sheathed and connected with a transmission belt 4; the body 1 is horizontally provided with a horizontal plate 8 abutting against the cam 6, and the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com