Linear type efficient electrostatic spinning spray nozzle

An electrospinning, linear technology, used in filament/line forming, spinneret assemblies, textiles and papermaking, etc., which can solve the problems of high investment in industrial applications, characterization of nanofiber mechanical properties, and low electrospinning yields and other problems, to achieve the effect of improving spinning efficiency, avoiding long-term contact, and reducing thermo-oxidative degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

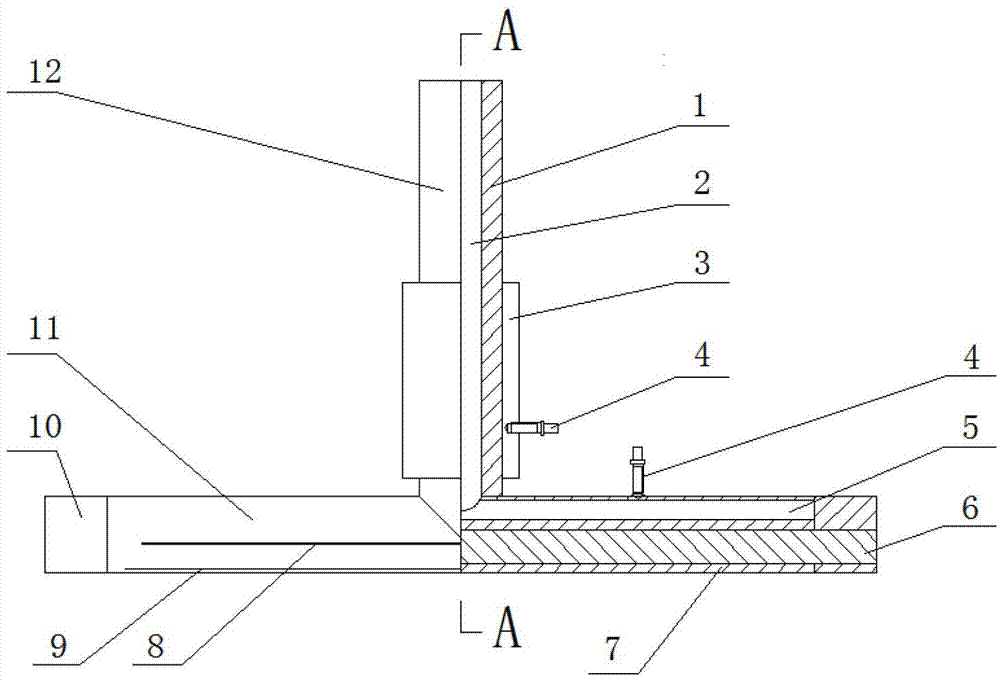

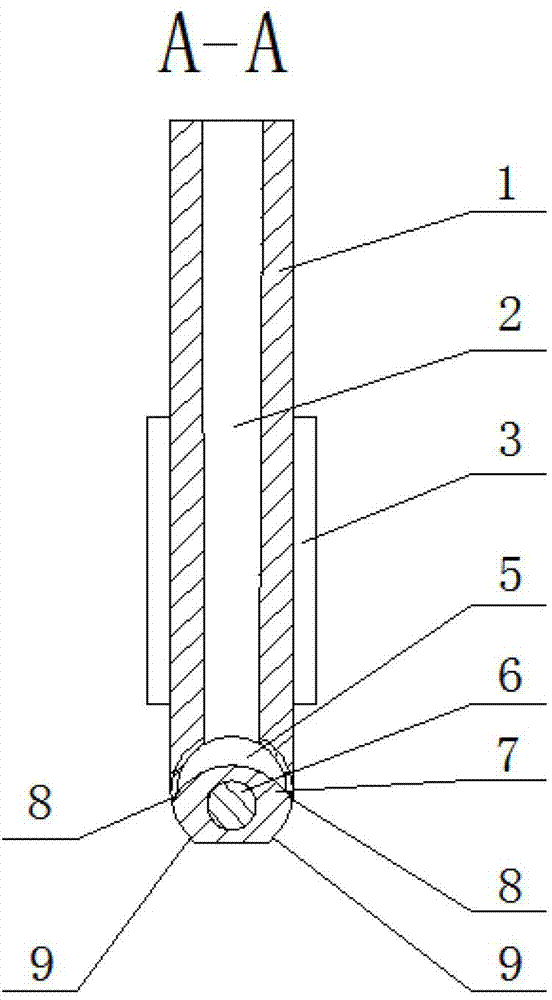

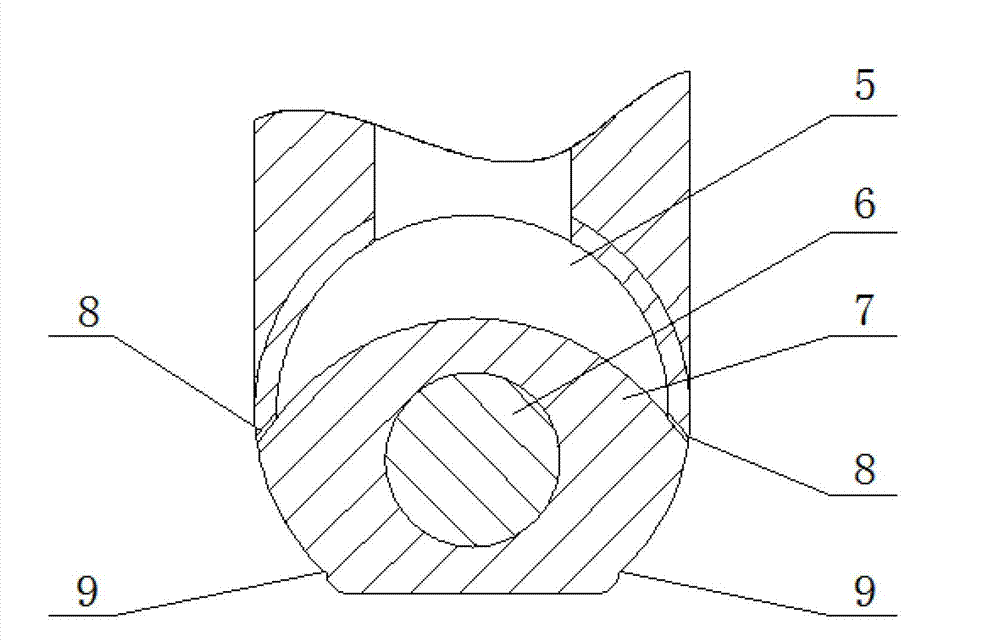

[0011] The present invention is a linear high-efficiency electrostatic spinning nozzle, which mainly includes a vertical barrel (12) and a horizontal barrel (11) connected to the vertical barrel (12) by welding, and the inside of the horizontal barrel (11) is crescent-shaped The flow channel (5), wherein the central angle of the arc surface of the crescent-shaped flow channel (5) is 100°, the radius is 12mm, and the two sides of the crescent-shaped flow channel (5) are linear nozzles (8), which are circular with the crescent-shaped flow channel The arc surface is tangent, the gap width of the straight nozzle (8) is 0.3mm, the upper heating ring (3) for material preheating is located at the lower part of the vertical barrel (12), and the heating rod (6) for heating the material is located in the horizontal barrel (11) Just below the inner crescent-shaped flow channel (5), the outer diameter is 8mm, the thermocouple (4) is fixed on the vertical barrel (12) and the horizontal barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com