Preparation method of chalcogenide glass

A chalcogenide glass and glass technology, applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problems of glass batch stability differences, non-continuous production, low production efficiency, etc., to reduce production costs, production The effect of cost reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

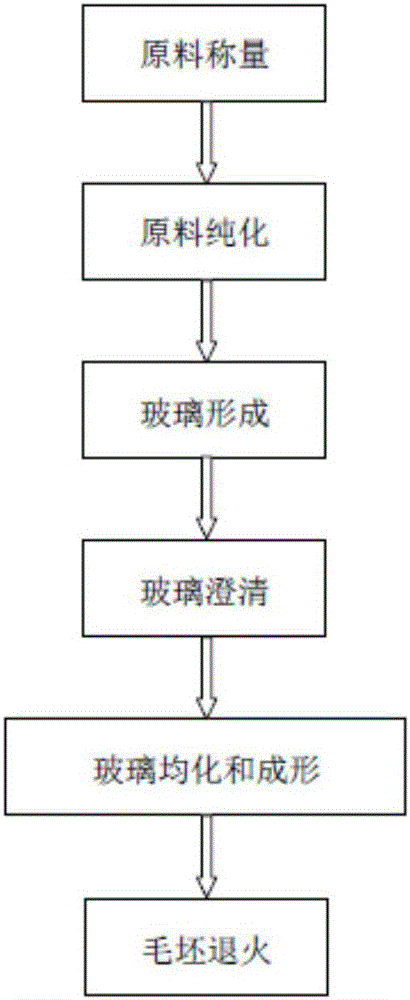

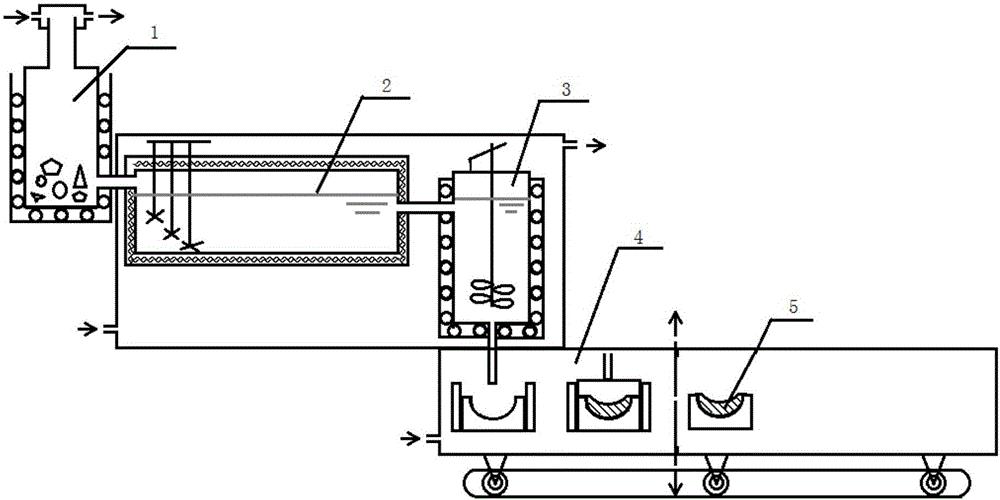

[0032] like figure 1 As shown, one embodiment of the present invention proposes a kind of preparation method of continuous melting and leakage forming chalcogenide glass, which comprises the steps:

[0033] 1) Raw material weighing: According to the design ratio, weigh the required amount of glass raw materials in an anhydrous and oxygen-free glove box, and mix them to form a glass batch. The purity of the glass raw material used is higher than 99.999%, and the particle size of the material is 2-10mm; the weighed batch material is put into a quartz container and sealed. Further, an oxygen scavenger Al with a purity ≥ 99.999% is added to the glass batch material, and the doping amount is 0.05-0.1‰ of the total weight of the batch material;

[0034] 2) Purification of raw materials: Open the valve at the upper end of the quartz container, inject the required batch materials into the raw material purification and formation unit, vacuumize and heat the raw material purification a...

Embodiment 1

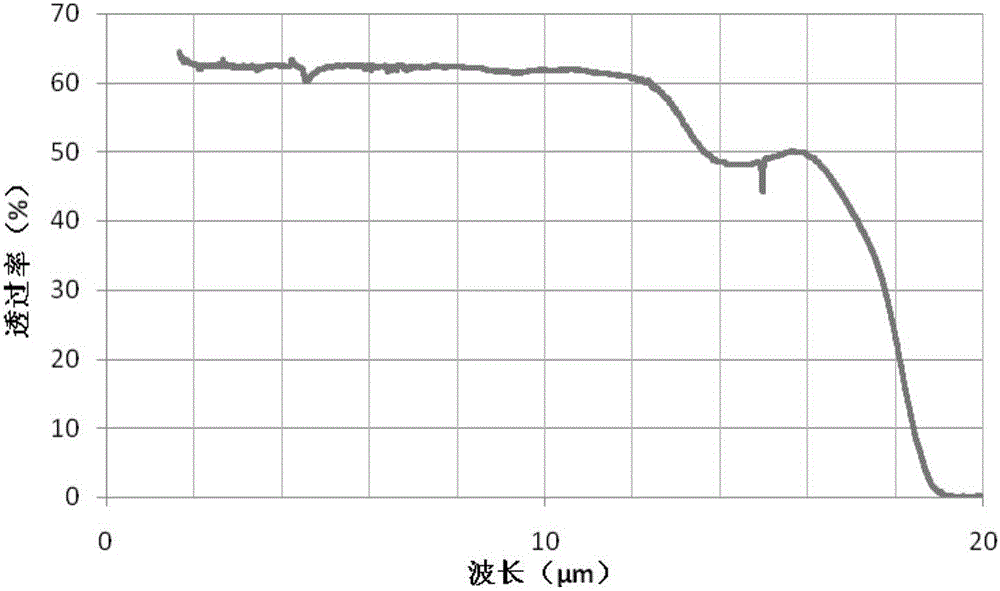

[0043] One embodiment of the present invention proposes continuous melting and blowout forming Ge 22 As 20 Se 58 Preparation method of chalcogenide glass.

[0044] (1) Raw material weighing: Prepare three batches with a total weight of 30kg in an anhydrous and oxygen-free environment, and add them to three sets of raw material purification-glass forming units respectively. The dimensions of the dehydroxylated quartz crucible used are Φ160mm*H400mm*δ5mm;

[0045] (2) Purification of raw materials: close the top and bottom discharge valves of the quartz crucible, vacuumize the quartz crucible and heat it outside, so that the temperature of the raw materials in the crucible reaches 320 °C, and the vacuum degree is less than 1×10 -2 Pa, continuous baking for 5 hours;

[0046] (3) Glass formation: close the quartz crucible and the external valve, further heat the batch material in the quartz crucible to 850°C, and keep it at this temperature for 20 hours to fully combine the gla...

Embodiment 2

[0052] One embodiment of the present invention proposes continuous melting and blowout forming Ge 28 Sb 12 Se 60 Preparation method of chalcogenide glass.

[0053] (1) Raw material weighing: Prepare three batches with a total weight of 30kg in an anhydrous and oxygen-free environment, and add them to three sets of raw material purification-glass forming units respectively. The dimensions of the dehydroxylated quartz crucible used are Φ160mm*H400mm*δ5mm;

[0054] (2) Purification of raw materials: close the top and bottom discharge valves of the quartz crucible, vacuumize the quartz crucible and heat it outside, so that the temperature of the raw materials in the crucible reaches 320 °C, and the vacuum degree is less than 1×10 -2 Pa, continuous baking for 5 hours;

[0055] (3) Glass formation: close the quartz crucible and the external valve, further heat the batch material in the quartz crucible to 860°C, and keep it at this temperature for 20 hours to fully combine the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com