Metal surface acute deformation alloying method

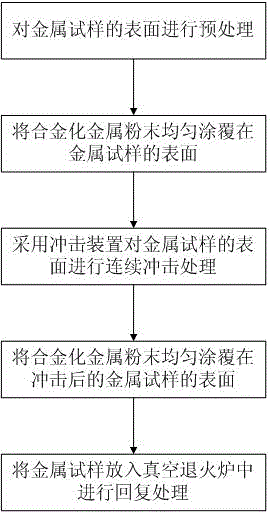

A metal surface and alloying technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of low efficiency, low metal surface alloying effect, complex process, etc., achieve simple process, prevent cracks, and improve comprehensive mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Surface deformation alloying of 20 steel

[0037] First, cut the 20-steel plate into 30mm×40mm samples, wash the samples with acetone, remove the oil on the surface of the material, wash it with water, and grind it with W20 and W50 sandpaper until there are basically no obvious scratches on the surface of the material and In the same direction, wash with alcohol and dry for later use. Afterwards, the impact alloying treatment is carried out, and the impact equipment is used for deformation treatment. When using, the sample is clamped, 3mm Cr powder is spread on the surface of the sample, and the impact device is used for impact treatment. As the Cr powder, 3.5N (99.95% purity) pure Cr powder with a particle size of about 75 μm (200 mesh) was used. For impact treatment, an impact drill with a radius of curvature of 2mm is used, the impact energy is 1J, the impact frequency is 80 times per second, and the impact time is about 30 minutes. Finally, spread a lay...

Embodiment 2

[0039] Embodiment 2: Surface deformation alloying of Q235 steel

[0040] First, cut the Q235 steel plate into 30mm×40mm samples, clean the samples with acetone, remove the oil on the surface of the material, wash it with water, and grind it with W20 and W50 sandpaper until there are basically no obvious scratches on the surface of the material and In the same direction, wash with alcohol and dry for later use. Afterwards, the impact alloying treatment is carried out, and the impact equipment is used for deformation treatment. When using, the sample is clamped, 1mm of Cr powder is spread on the surface of the sample, and the impact head is used to impact the surface of the sample. As the Cr powder, 3.5N (99.95% purity) pure Cr powder with a particle size of about 75 μm (200 mesh) was used. During the impact treatment, a 2mm impact drill bit is used, the impact energy is 3J, the impact frequency is 20 times / second, and the impact is about 5min. Finally, spread a layer of Cr po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com