Low-cost and long-service-life surface layer gradient material with stainless steel performance and preparing method of low-cost and long-service-life surface layer gradient material

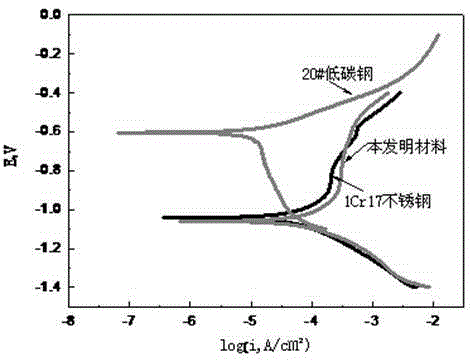

A gradient material, stainless steel technology, applied in metal material coating process, coating, heating inorganic powder coating, etc., can solve the problems of high cost of stainless steel, shallow alloying depth, low alloying degree, etc., and achieve the production cost The effect of reducing, high alloying depth, alloying degree and alloying depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

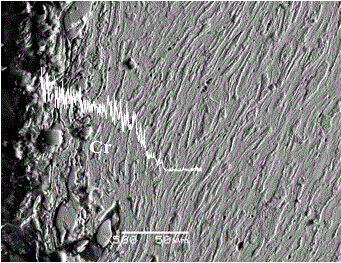

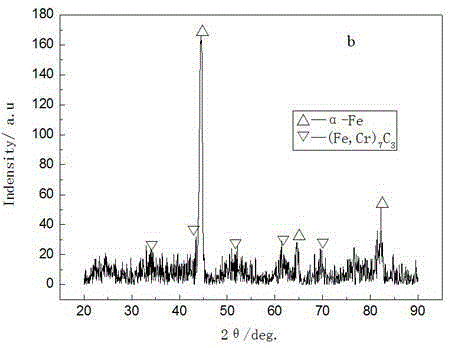

[0035]The surface of the low-carbon steel 10# steel plate with a thickness of 10mm is gradually finely ground to No. 10 SiC sandpaper with No. 50 SiC sandpaper, polished, etched with dilute nitric acid, and finally rinsed with alcohol and dried. Wire-cut the surface-treated steel plate into 20mm×20mm×10mm samples, put the samples in a vacuum heat treatment furnace at 300°C for 15 minutes, and quickly take out the samples and place them in a fixed sample mold to fix them. 3.5N pure Cr powder with a particle size of 75 μm (200 mesh), using an impact device to continuously impact the surface of the sample, the radius of curvature of the impact end is 2mm, the impact time is 15min, the impact energy is 1.7J, and the impact rate is 50 times / second. The continuous impact time at the same position, that is, the moving speed of the impact end is 2s, and Cr powder is added in time during the impact process. After the impact is completed, remove the residual Cr powder, clean the impact ...

Embodiment 2

[0037] 30# steel (medium carbon steel) with a thickness of 10 mm is selected as the base material, and the pretreatment process is the same as that in Example 1. Put the sample into a vacuum heat treatment furnace for preheating at 200°C for 30 minutes, then take it out and place it in a fixed sample mold, and then cover the surface with a uniform mixture of 3.5N pure Cr powder and Ti powder with a particle size of 75 μm (200 mesh) (Cr powder The mass ratio to Ti powder is 20:1), and the impact device is used to continuously impact the surface of the sample. The impact parameters are: the radius of curvature of the impact end is 1mm, the impact time is 5min, the impact energy is 1J, and the impact rate is 20 times / second , the continuous impact time at the same position, that is, the moving speed of the impact end is 1s, and the mixture of Cr powder and Ti powder is added in time during the impact process. After the impact is completed, remove the remaining Cr and Ti powders, ...

Embodiment 3

[0039] The industrial pure iron with a thickness of 10 mm is selected as the base material, and the pretreatment process is the same as that in Example 1. Put the sample into a vacuum heat treatment furnace to preheat at 400°C for 10 minutes, then take it out and place it in a fixed sample mold, and then cover the surface with a uniform mixture of 3.5N pure Cr powder, Ni powder and Mo powder with a particle size of 75 μm (200 mesh). (The mass ratio of Cr, Ni and Mo powder is 20:10:1), the impact device is used to continuously impact the surface of the sample, the radius of curvature of the impact end is 4mm, the impact time is 30min, the impact energy is 3J, and the impact rate is 80 times / second, the continuous impact time at the same position, that is, the moving speed of the impact end is 5s, and the mixed powder of Cr, Ni, and Mo is added in time during the impact process. After the impact is completed, remove the residual Cr, Ni, and Mo mixed powder, clean the impacted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com