Al-Zn composite material and solid-state alloying manufacturing method thereof

A composite material and alloying technology, which is applied in the field of metal processing, can solve problems such as high cost and energy consumption, numerous influencing factors, and complicated process flow, and achieve the advantages of avoiding solidification cracks and pores, high alloying degree, and low residual stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for preparing Al-Zn composite material by solid state alloying in this embodiment comprises the following steps:

[0026] 1) Select the aluminum plate, and process small holes with a depth of 3.5mm on the aluminum plate in a row;

[0027] 2) Fill the small hole in step 1) with zinc powder and compact it;

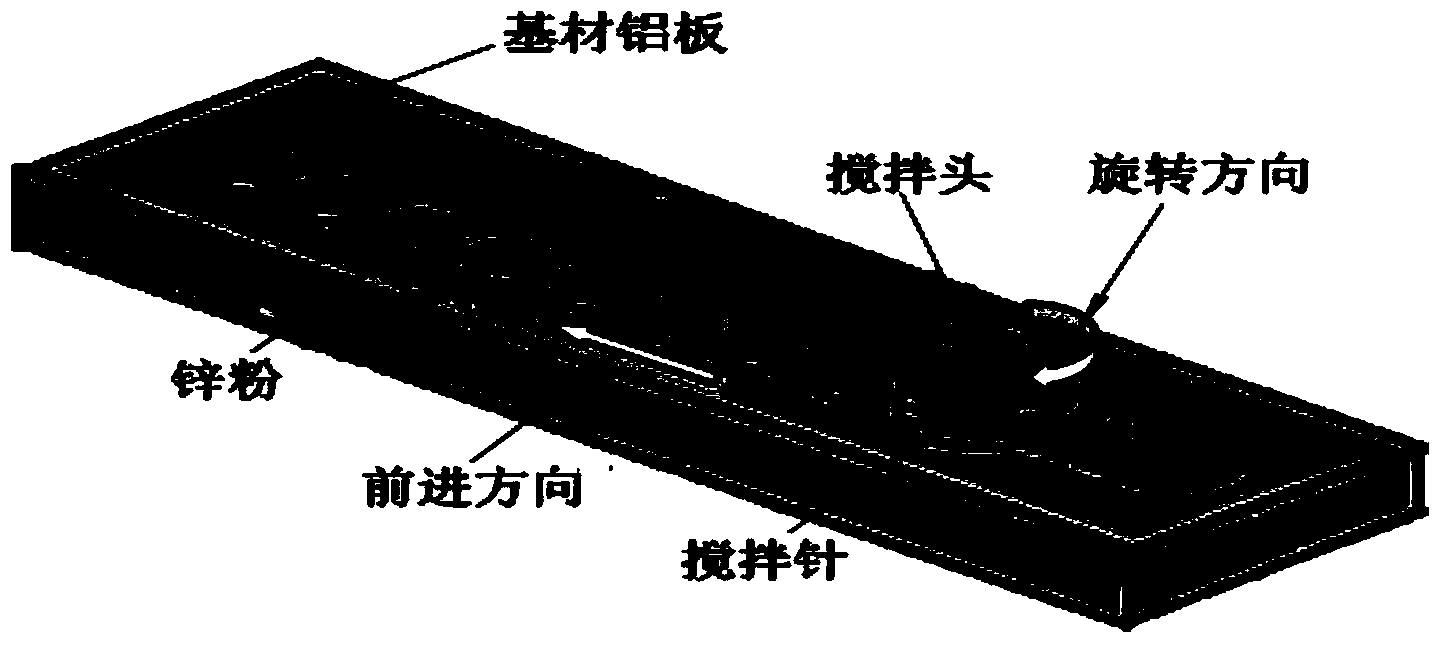

[0028] 3) The small hole and the surrounding area filled with zinc powder by mechanical stirring and friction, the total area of the processing area is twice the area of the small hole when stirring, the depth of the stirring needle is 4mm, the rotation speed of the stirring head is 940r / min, and the walking speed is 15mm / min, the friction stir process in this embodiment is as follows figure 1 shown.

[0029] As an improvement of this embodiment, the aluminum plate selected in step 1) is the 1100 pure aluminum plate shown, with a thickness of 6mm and a specific size of 300mm×100mm×6mm.

[0030] As another improvement of this embodiment, the particle...

Embodiment 2

[0035] The method for preparing Al-Zn composite material by solid state alloying in this embodiment comprises the following steps:

[0036] 1) Select the aluminum plate, and process holes with a depth of 4mm on the aluminum plate in a row;

[0037] 2) Fill the small hole in step 1) with zinc powder and compact it;

[0038] 3) The small hole and the surrounding area filled with zinc powder by mechanical stirring and friction, the total area of the processing area is 1.5 times the area of the small hole when stirring, the rotation speed of the stirring head is 960r / min, the depth of the stirring needle is 4.5mm, and the walking speed is 15mm / min.

[0039] As an improvement of this embodiment, the selected aluminum plate in step 1) is a 1100 pure aluminum plate with a thickness of 7mm.

[0040] As another improvement of this embodiment, the particle size of Zn powder selected in step 2) is 300 mesh.

[0041] As a further step of this embodiment, the small holes processed ...

Embodiment 3

[0044] The method for preparing Al-Zn composite material by solid state alloying in this embodiment comprises the following steps:

[0045] 1) Select the aluminum plate, and process holes with a depth of 3mm on the aluminum plate in a row;

[0046] 2) Fill the small hole in step 1) with zinc powder and compact it;

[0047] 3) The small hole and the surrounding area filled with zinc powder are mechanically stirred and frictionally stirred. The total area of the processing area is 2.5 times the area of the small hole when stirring, the rotation speed of the stirring head is 920r / min, the depth of the stirring needle is 4mm, and the walking speed is 15mm / min.

[0048] As an improvement of this embodiment, the selected aluminum plate in step 1) is a 1100 pure aluminum plate with a thickness of 5.5 mm.

[0049] As another improvement of this embodiment, the particle size of Zn powder selected in step 2) is 200 mesh.

[0050] As a further step of this embodiment, the small h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com