Quantum dot synthesis method

A synthesis method and quantum dot technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of low alloying degree of CdZnS transition layer, reduced luminous efficiency of quantum dots, semi- Increased peak width and other issues to achieve the effect of reducing internal defects, uniform growth of quantum dots, and narrow half-peak width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In some preferred embodiments, the preparation method of the zinc source comprises: reacting a mixed reaction system comprising short-chain fatty acid zinc, amine, phosphine source and solvent at 80-120° C. for 30 min-3 h.

[0021] Further, the zinc source concentration in the mixed reaction system is >0 and ≤2mmol / ml, preferably 1-2mmol / ml.

[0022] Further, the molar ratio of the phosphine source, short-chain fatty acid zinc and amine is 2:3:3˜1:8:32.

[0023] Further, the short-chain fatty acid zinc comprises zinc acetate (Zn(Ac) 2 ), zinc acetate dihydrate (Zn(Ac)·2H 2 O) and zinc propionate, etc., any one or a combination of two or more, preferably zinc acetate, zinc acetate dihydrate, but not limited thereto.

[0024] Further, the amines include any one or a combination of two or more of oleylamine, octadecylamine, cetylamine, tetradecylamine, dodecylamine, n-octylamine and trioctylamine, preferably oleylamine , but not limited to this.

[0025] Further, the p...

Embodiment 1

[0059] The zinc source preparation process used in the present embodiment is as follows:

[0060] Zinc acetate dihydrate 8.6g 40mmol Alpha reagent 97%

[0061] Oleylamine 40mmol Sigma Reagent 70%

[0062] Octadecene 80ml Alpha Reagent 90%

[0063] Put the above-mentioned raw materials in a 250ml three-necked flask, vacuumize and replace the argon three times, then raise the temperature to 100°C until there are no bubbles, insert the needle under the liquid surface and blow argon for 30min, and add 5ml of diphenylphosphine.

[0064] Preparation method of quantum dots

[0065] 1mlCd(OA) 2 , 10mlZn(OA) 2 Put 20ml of ODE in a 100ml three-neck flask, heat up to 120°C and evacuate until there are no bubbles. After obtaining a colorless transparent liquid, blow argon, heat up to 300°C, inject TOPSe 2M 0.2ml at 300°C, and then inject at 300°C Leave on for 30 minutes. Add Cd(OA) dropwise at 300°C 2 , Zinc source, TOPS, then cool down to end the reaction.

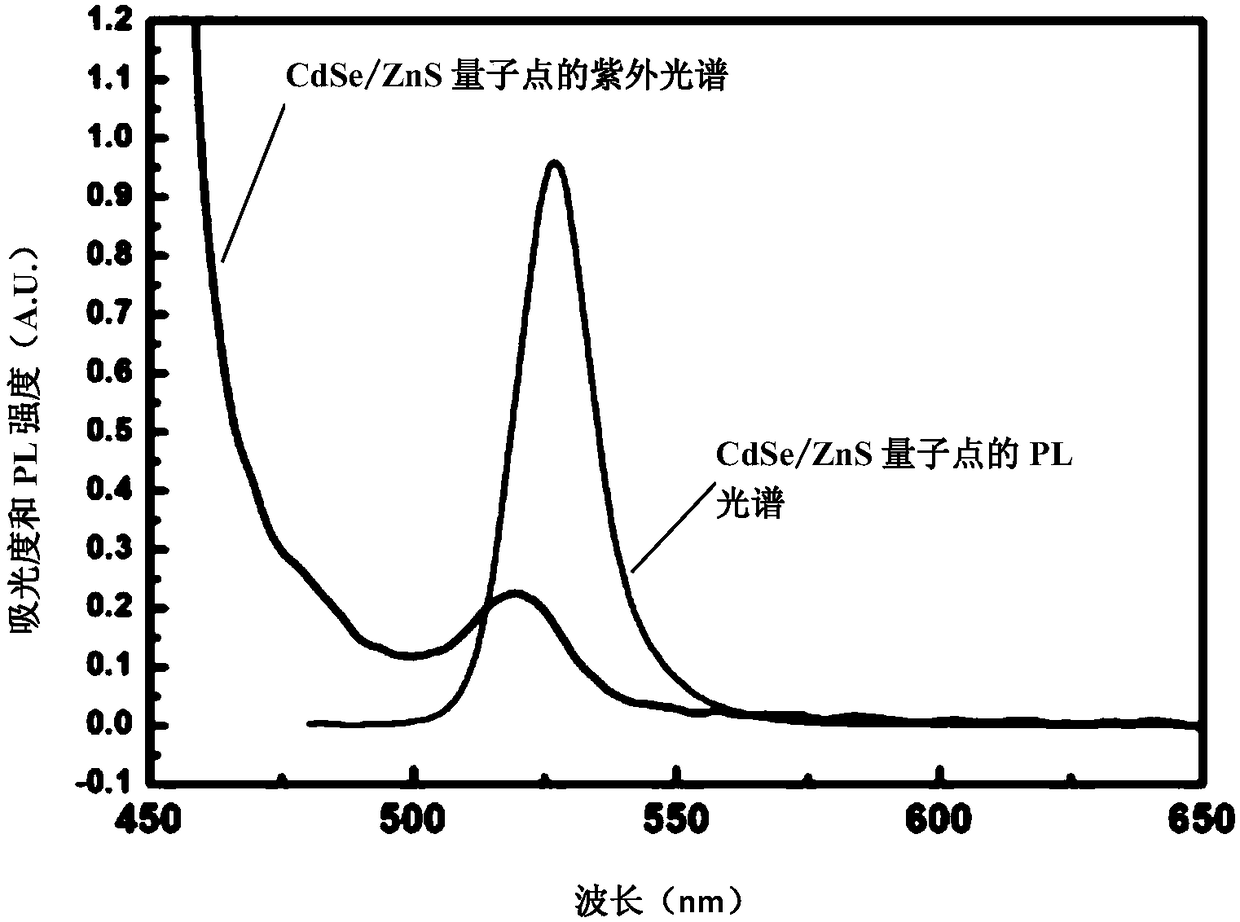

[0066] The optical ...

Embodiment 2

[0068] The zinc source preparation process used in the present embodiment is as follows:

[0069] Zinc acetate dihydrate 8.6g 40mmol Alpha reagent 97%

[0070] Octadecylamine 40mmol Sigma Reagent 70%

[0071] Put the above-mentioned raw materials in a 250ml three-necked flask, vacuumize and replace the argon three times, then raise the temperature to 100°C until there are no bubbles, insert the needle under the liquid surface and blow argon for 30min, and add 1ml of diphenylphosphine.

[0072] Preparation method of quantum dots

[0073] 1mlCd(OA) 2 , 10ml Zn(OA) 2 Put 20ml of ODE in a 100ml three-necked flask, heat up to 120°C and evacuate until there are no bubbles. After obtaining a colorless and transparent liquid, blow argon, heat up to 300°C, inject TOPSe 2M0.2ml at 300°C quickly, and then Leave on for 30 minutes. Add Cd(OA) dropwise at 300°C 2 , Zinc source, TOPS, then cool down to end the reaction.

[0074] The optical properties of the quantum dots obtained in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com