High-temperature preparation method of proton exchange membrane fuel cell binary alloy catalyst

A technology of proton exchange membrane and alloy catalyst, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of affecting the catalytic activity of catalyst particles and the cost of pure platinum catalyst High, battery performance degradation and other issues, to achieve the effect of easy mass production, low price, and reduce adsorption energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

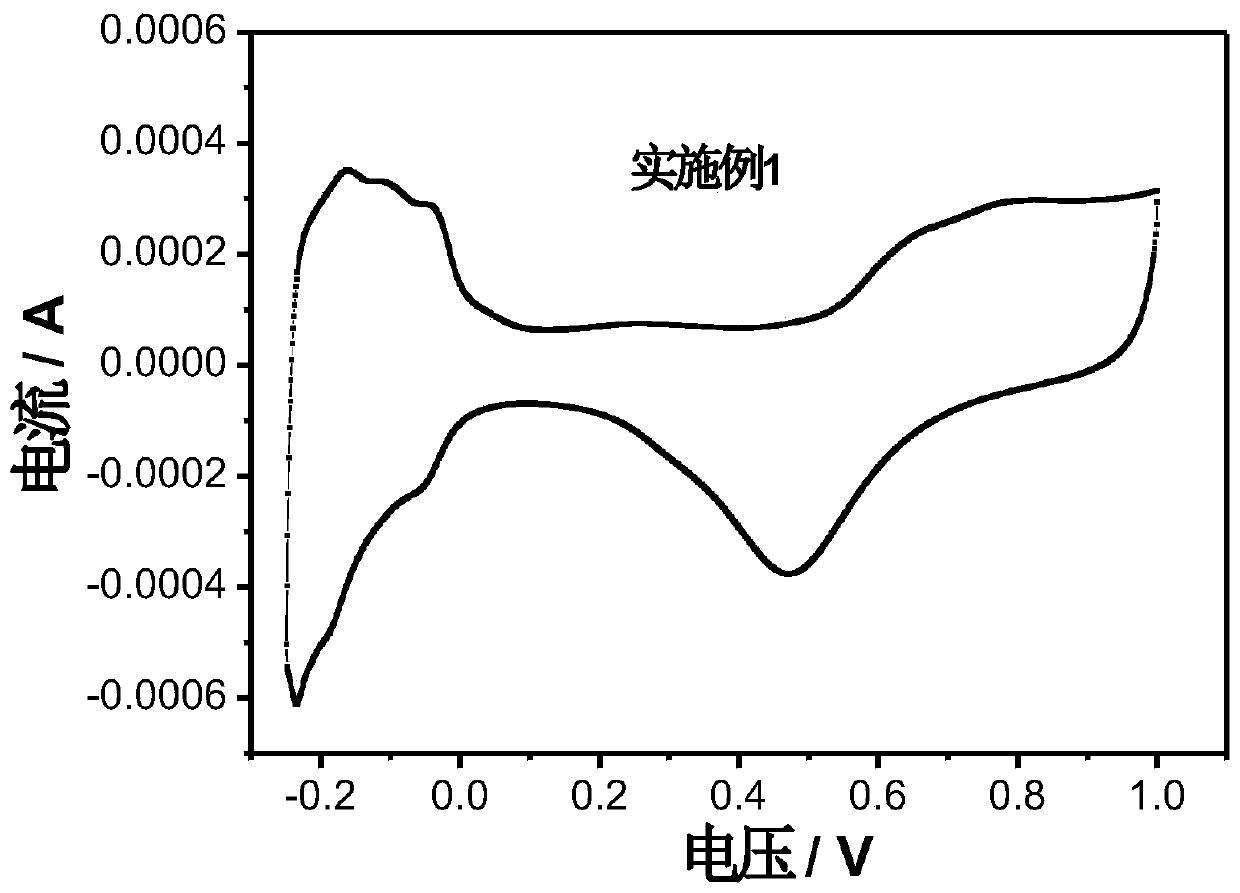

Embodiment 1

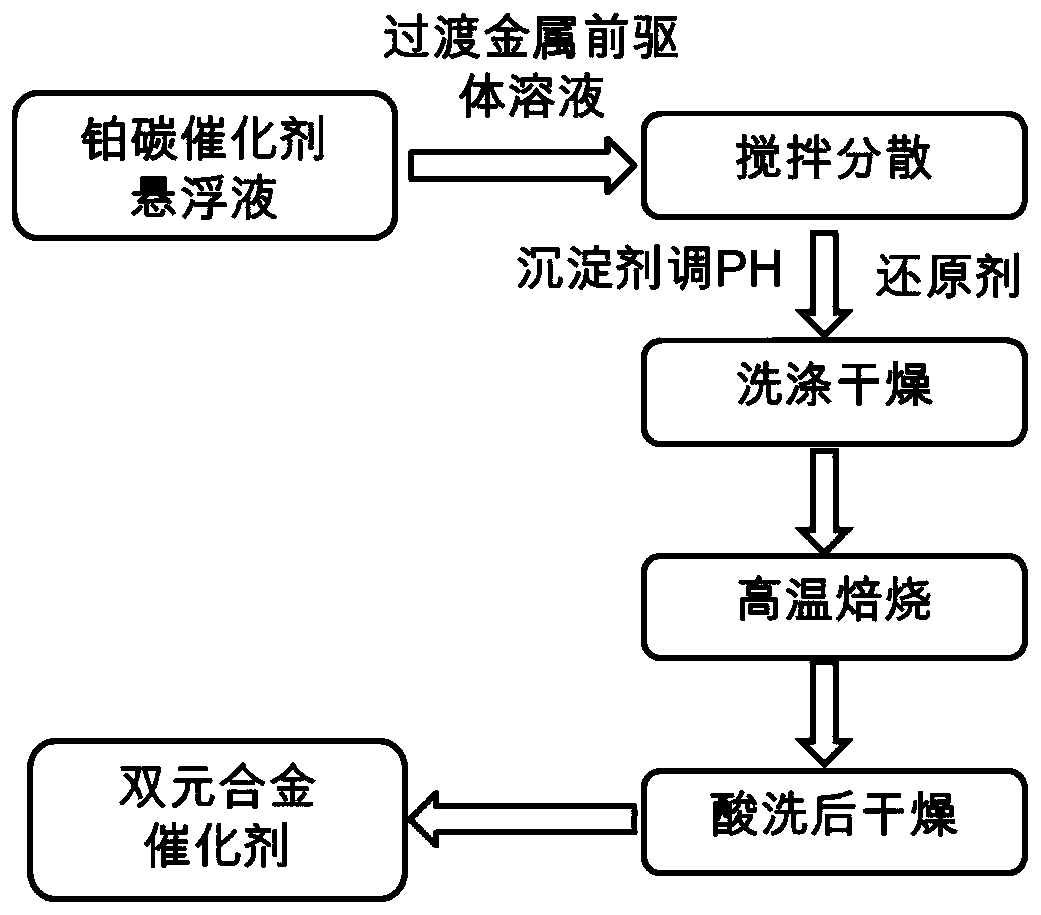

[0031] A high-temperature preparation method for a proton exchange membrane fuel cell binary alloy catalyst, comprising the following steps:

[0032] (1) Weigh 0.5 g of 40% Pt / C catalyst (Johnson Matthey Company, UK, abbreviated as JM Company) into a beaker, add 40 mL of deionized water, add 10 mL of cobalt chloride aqueous solution with a concentration of 0.05 mol / L, and fully Stir into a dispersion;

[0033] (2) Weigh 0.8g of sodium hydroxide into another beaker, add 20mL of water, fully dissolve to make a precipitant solution; under full stirring, add the precipitant to the dispersion to adjust the pH to 12, stir for 10min, Stand at room temperature for 30 minutes, pour out the supernatant and wash thoroughly;

[0034] (3) After drying in an oven at 50°C, put the catalyst precursor powder into a tube furnace, pass nitrogen gas for 30 minutes, then roast at 300°C for 2 hours under nitrogen atmosphere, and add sulfuric acid aqueous solution with a concentration of 0.5 mol / L ...

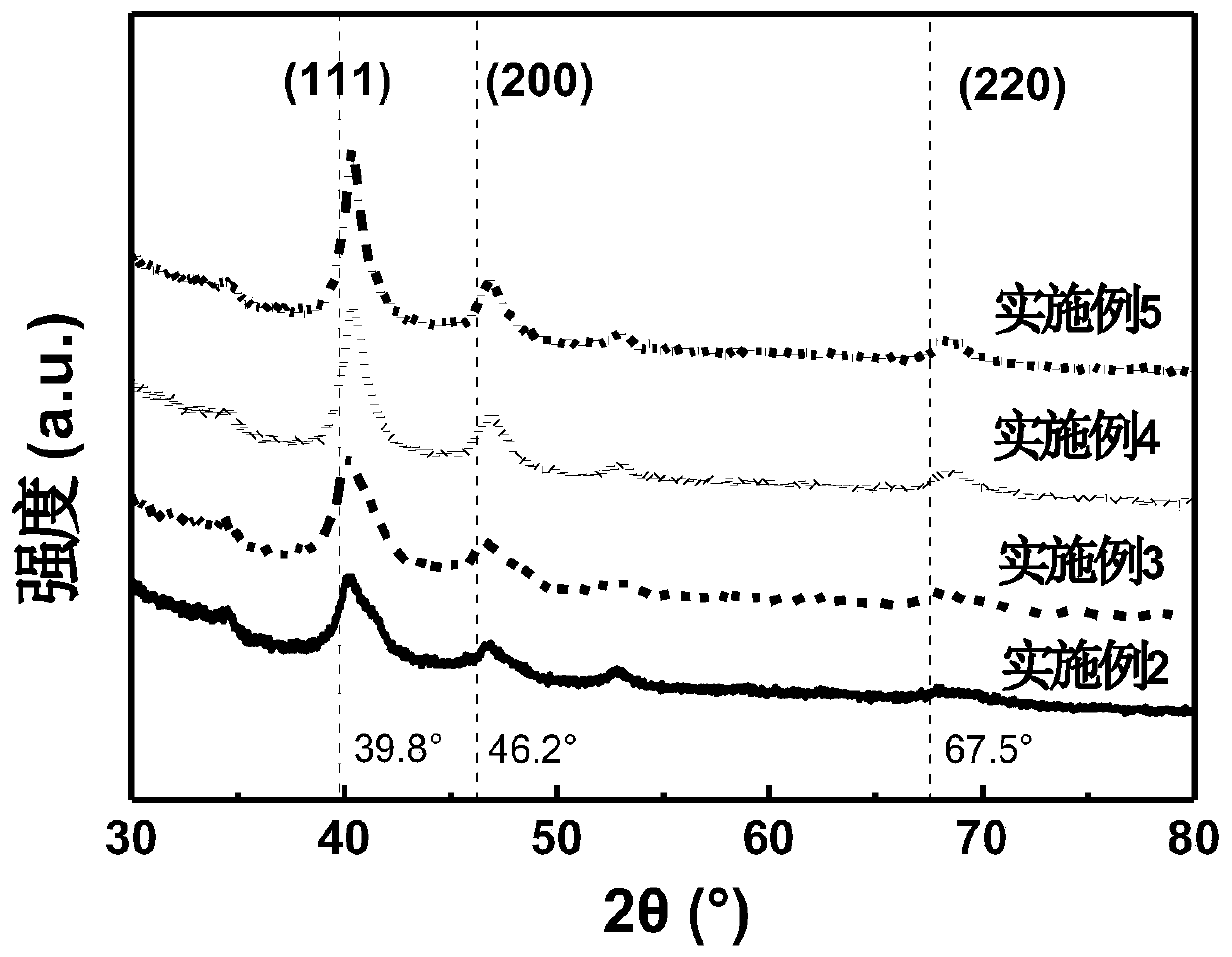

Embodiment 2

[0036] A high-temperature preparation method for a proton exchange membrane fuel cell binary alloy catalyst, comprising the following steps:

[0037] (1) Weigh 0.5 g of 40% Pt / C catalyst (JM Company) into a beaker, add 80 mL of deionized water, 20 mL of ethylene glycol, add 1 mL of cobalt nitrate aqueous solution with a concentration of 0.5 mol / L, and stir well to form a dispersed liquid;

[0038] (2) Weigh 0.4g of sodium hydroxide and 0.3g of sodium carbonate into another beaker, add 20mL of water to fully dissolve into a precipitant solution; under full stirring, add the precipitant to the dispersion to adjust the pH to 10 , stirred for 10 minutes, stood at room temperature for 30 minutes, poured the supernatant and washed thoroughly;

[0039] (3) After drying in an oven at 50°C, put the catalyst precursor powder into a tube furnace, pass nitrogen gas for 30 minutes, and roast at 750°C for 1 hour in a nitrogen-hydrogen mixed gas atmosphere, and add the concentration of 1 mo...

Embodiment 3

[0041] A high-temperature preparation method for a proton exchange membrane fuel cell binary alloy catalyst, comprising the following steps:

[0042] (1) Weigh 0.5 g of 40% Pt / C catalyst (self-made) into a beaker, add 20 mL of deionized water, add 2 mL of nickel nitrate aqueous solution with a concentration of 0.4 mol / L, and stir well to form a dispersion;

[0043] (2) Weigh 0.8g of sodium hydroxide and 0.4g of sodium sulfite into another beaker, add 40mL of water, fully dissolve into a precipitant solution; under full stirring, add the precipitant to the dispersion to adjust the pH to 9, Stir for 10 minutes, let stand at room temperature for 30 minutes, pour out the supernatant and wash thoroughly;

[0044] (3) After drying in an oven at 50°C, put the catalyst precursor powder into a tube furnace, pass nitrogen gas for 30 minutes, and roast at 850°C for 1 hour in an argon-hydrogen atmosphere, and add sulfuric acid with a concentration of 0.1 mol / L after cooling down Pickle w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com