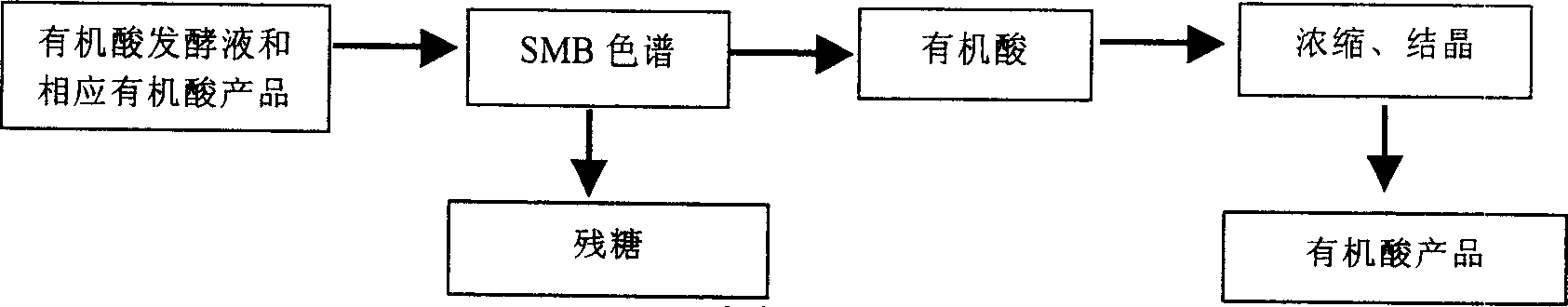

Method for separating remaining sugar and extracting organic acid from organic acid fermentation liquor and corresponding organic acid mother liquor

A technology for organic acid ions and organic acids, which is applied in the field of separating residual sugar to purify and prepare organic acid products, can solve the problems of serious resin surface pollution, degradation and loss of effective components, and increase energy consumption for concentration, and achieves low production cost, resin High utilization rate and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

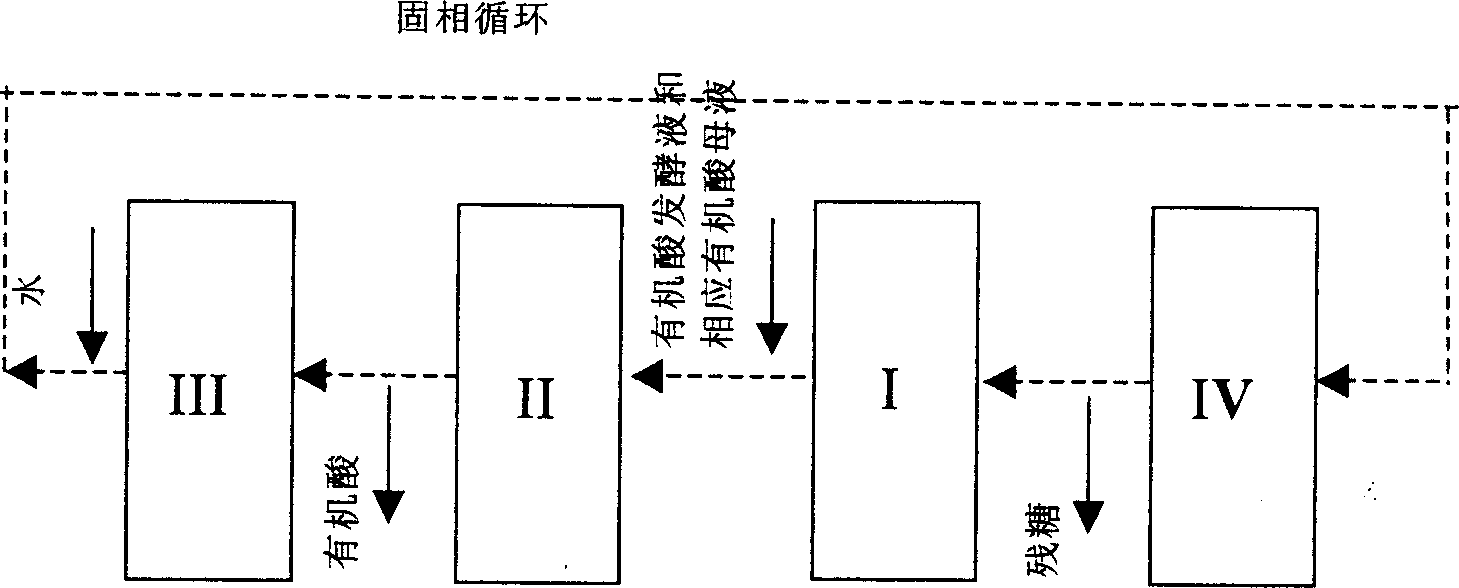

Method used

Image

Examples

preparation example Construction

[0041] In the preparation method of the bulk resin of the present invention, the reaction conditions of the suspension polymerization may be well-known suspension reaction conditions in the art. In a preferred example of the present invention, the reaction temperature of the suspension reaction is 60-110°C, preferably 75-90°C, the pressure is normal pressure, and the reaction time is 4-10 hours, preferably 6 to 7 hours.

[0042] 2. Basic anionic functionalization of resin matrix

[0043] The body resin synthesized by the present invention is, for example, a gel or macroporous network cross-linked interpolymer containing acrylate groups and / or methacrylate groups, and the body resin is swollen under divinylbenzene or acetophenone With diethylenetriamine, triethylenetetramine, tetraethylenepentamine, polyethylene polyamine and other amines (-CONH(C 2 h 4 NH) 2 H, -CONH (C 2 h 4 NH) 3 H, -CONH (C 2 h 4 NH) 4 H) Aminolysis is carried out to obtain an acrylic acid series ...

Embodiment 1

[0065] Citric acid mother liquor: temperature 70°C

[0066] Resin type: Basic anion resin synthesized by 20% styrene and 80% methyl acrylate

[0067] Feed material: citric acid concentration 67%; residual sugar amount (after being diluted 10 times, represented by easy carbon index) 0.5

[0068] Pass this mother liquor through the simulated moving bed, and the operating conditions of the simulated moving bed are as follows: separation temperature 70°C, system pressure 1.1Mpa, feeding amount of feed liquid is 1L / h, feeding amount of eluting water is 3.5L / h, feeding 24 Equilibrium is reached after hours. The output obtained is as follows

[0069] Citric acid output: citric acid concentration 32%; residual sugar amount (expressed by easy carbon index) 0.04 (volume is 2 times of feed citric acid mother liquor)

[0070] Residual sugar discharge: citric acid concentration 1.1%; residual sugar amount (indicated by easy carbon index) 0.78 (volume is 3 times of feed citric acid mothe...

Embodiment 2

[0072] Lactic acid fermentation concentrate: temperature 70°C

[0073] Resin type: Basic anionic resin synthesized with 40% styrene and 60% methacrylic acid

[0074] Feed material: lactic acid concentration 45%; residual sugar amount (after being diluted 20 times, represented by easy carbon index) 0.88

[0075] Pass this mother liquor through the simulated moving bed, and the operating conditions of the simulated moving bed are as follows: separation temperature 70°C, system pressure 1.1Mpa, feeding amount of feed liquid is 1L / h, feeding amount of eluting water is 3.5L / h, feeding 24 Equilibrium is reached after hours. The output obtained is as follows

[0076]Lactic acid output: lactic acid concentration 21%; residual sugar amount (after being diluted 5 times, represented by easy carbon index) 0.03 (volume is 1.5 times of the feed lactic acid fermentation concentrate)

[0077] Residual sugar discharge: lactic acid concentration 0.4%; residual sugar amount (after being dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com