SAPO (silicoaluminophosphate) molecular sieve as well as preparation method and application thereof

A silicoaluminophosphate and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of identification, weak characteristic diffraction peak width, and few synthetic reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

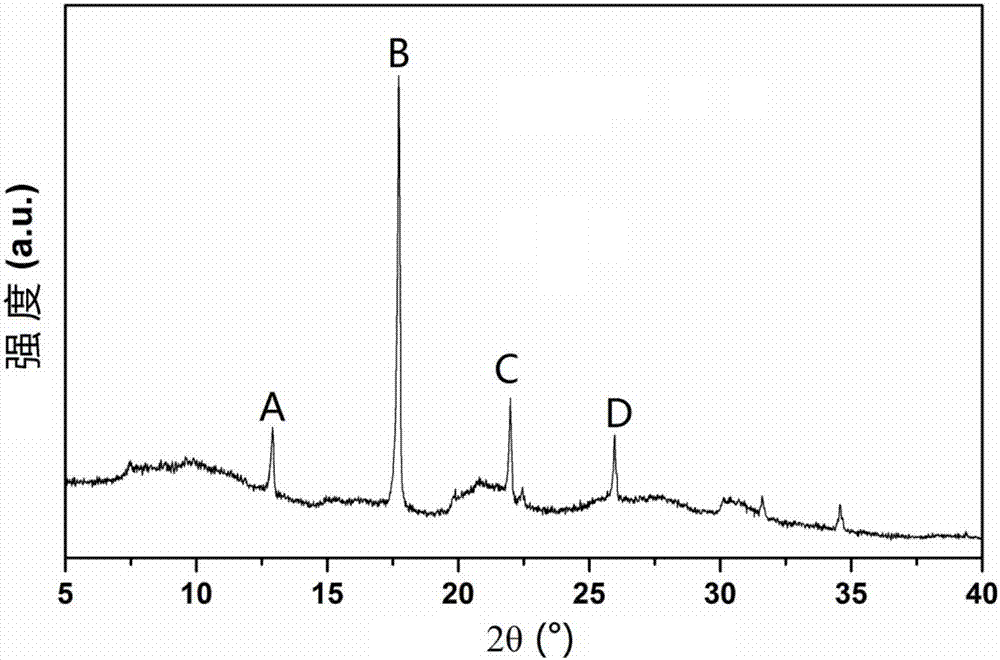

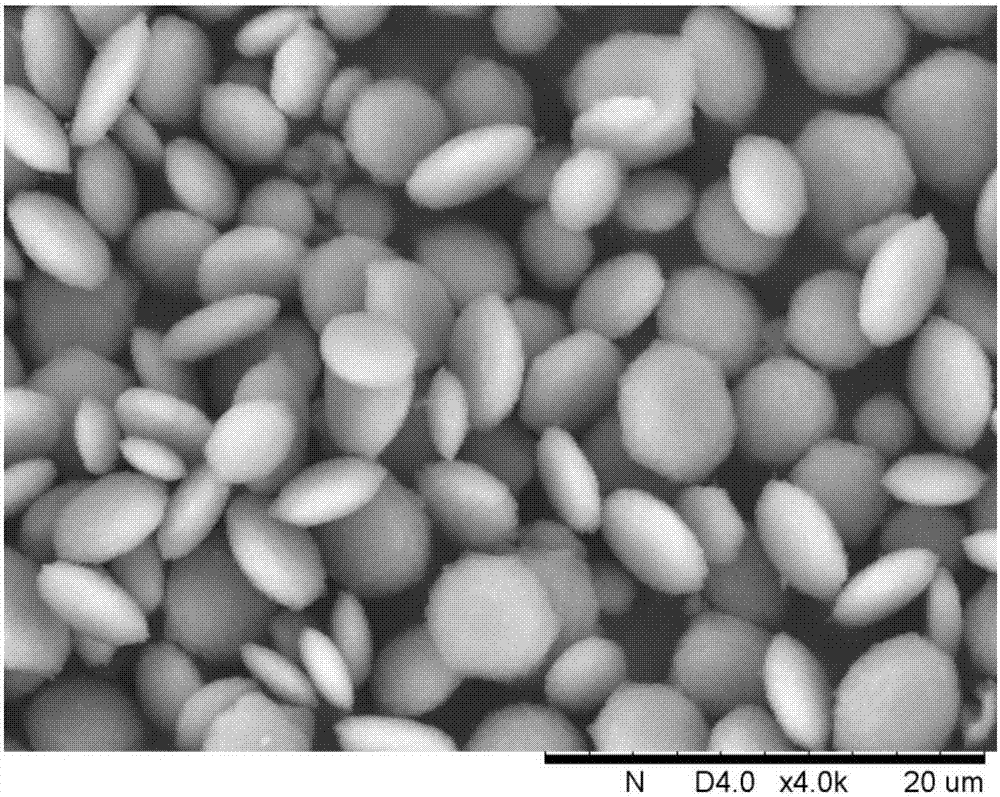

[0068] The molar ratios and crystallization conditions of each raw material are shown in Table 2. The specific batching process is as follows: the diisopropanolamine solid is dissolved into a liquid solvent in a 60°C water bath, and the pseudo-boehmite (Al 2 o 3 mass percentage content 72.5%) and diisopropanolamine (mass percentage content 99%) mixing and stirring, then add silica sol (SiO 2 Mass percent composition 30.04%), stir well, then phosphoric acid (H 3 PO 4 mass percentage 85%) was added dropwise, stirred evenly, then water and trimethylamine solution were added, stirred evenly to form a gel, and the gel was transferred to a stainless steel reaction kettle. After putting the reaction kettle into the oven, the temperature was programmed to 200°C for dynamic crystallization for 18 hours. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100° C. to obtain the molecular sieve raw powder sample. The XRD spectrum of the sample sh...

Embodiment 2-18

[0077] The specific batching ratio and crystallization conditions are shown in Table 2, and the specific batching process is the same as in Example 1.

[0078] Synthetic samples were analyzed by XRD, and the XRD data results were close to those in Table 3. According to different synthesis conditions, the 2θ value of diffraction peak A varies between 12.82°~13.2°, the 2θ value of diffraction peak B varies between 17.63°~18.15°, and the 2θ value of diffraction peak C varies between 21.80°~22.40° The 2θ value of the diffraction peak D varies between 25.92° and 26.38°. In the XRD diffraction data of all samples, the peak intensity of diffraction peak B is the largest, and the relative peak intensity is 1; According to the difference of synthetic conditions, the relative peak intensity of diffraction peak A (I A / I B ) varies between 0.1 and 0.5, the relative peak intensity of diffraction peak C (I C / I B ) varies between 0.1 and 0.7, the relative peak intensity of the diffract...

Embodiment 19

[0082] Carry out to the former powder sample of embodiment 1-10 13 C MAS NMR analysis by diisopropanolamine and trimethylamine 13 The C MAS NMR standard spectrum was compared, and it was found that the sample had resonance peaks of diisopropanolamine and trimethylamine at the same time. Quantitative analysis was carried out based on the unique non-overlapping NMR peaks of the two substances to determine the ratio of the two.

[0083] XRF was used to analyze the bulk phase element composition of the molecular sieve product, and CHN element analysis was performed on the raw powder samples of Examples 1-7. Integrated CHN elemental analysis, XRF and 13 As a result of C MAS NMR analysis, the composition of the obtained molecular sieve powder is shown in Table 4.

[0084] Table 4

[0085] Example Sample powder composition 1 0.04DIPA 0.09TMA (Si 0.162 Al 0.450 P 0.388 )O 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com