Metal organic framework material for adsorption separation of xenon gas and krypton gas and preparation method and application thereof

A technology of metal-organic framework and krypton gas, which is applied in the direction of specific gas purification/separation, separation methods, non-metallic elements, etc., can solve the problems of loss of separation performance, easy collapse of structure, poor stability, etc., and achieve good adsorption and separation effects, adsorption The effect of stable performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

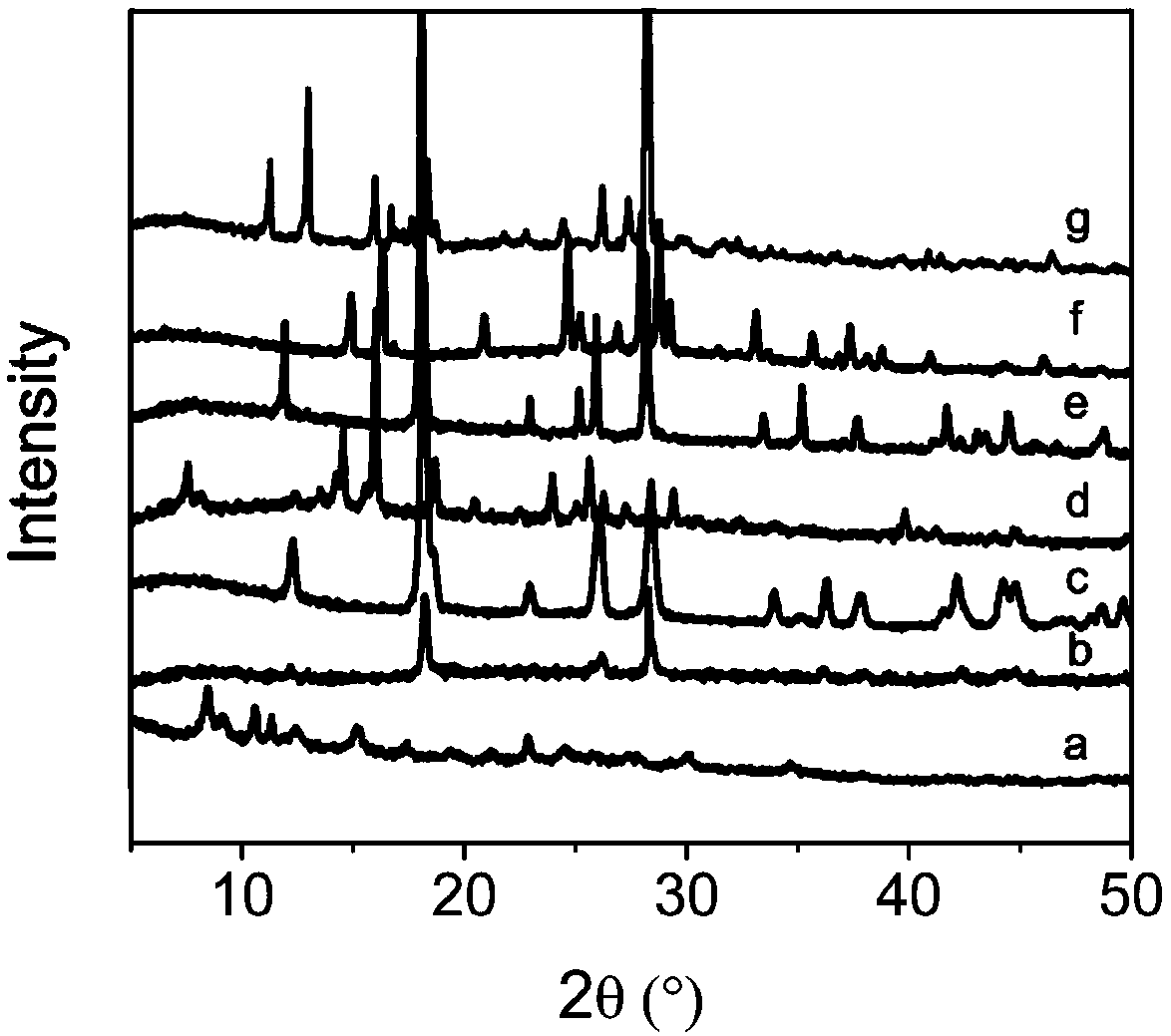

[0045] Mix 1.5mmol tin chloride, 1.5mmol 2,5-dihydroxy-1,4-benzoquinone, and 10mL deionized water, put them into a 25mL hydrothermal reactor, and stir and react at room temperature for 12 hours. After the reaction is completed, the solid obtained from the reaction is centrifuged and washed several times with deionized water and ethanol to obtain a purified metal-organic framework material. The purified adsorbent was vacuum degassed at 100 °C for 12 h to obtain the desolvated adsorbent, followed by gas adsorption.

[0046] In order to test the adsorption-separation performance of the above-synthesized MOFs, single-component adsorption isotherms of xenon and krypton were carried out using the above-mentioned adsorbents. Take 100mg of adsorbent and set the adsorption temperature at 0°C and 25°C. After testing, at 0°C and 1 bar, the adsorption amount of xenon gas reaches 1.10mmol / g, and the adsorption amount of krypton gas is only 0.57mmol / g; The adsorption amount of gas is only...

Embodiment 2

[0050] Mix 1.5mmol cobalt chloride hexahydrate, 1.5mmol 2,5-dihydroxy-1,4-benzoquinone, and 10mL deionized water, put them into a 25mL hydrothermal reactor, and stir and react at room temperature for 12 hours. After the reaction is completed, the solid obtained from the reaction is centrifuged and washed several times with deionized water and ethanol to obtain a purified metal-organic framework material. The purified adsorbent was vacuum degassed at 100 °C for 12 h to obtain the desolvated adsorbent, followed by gas adsorption.

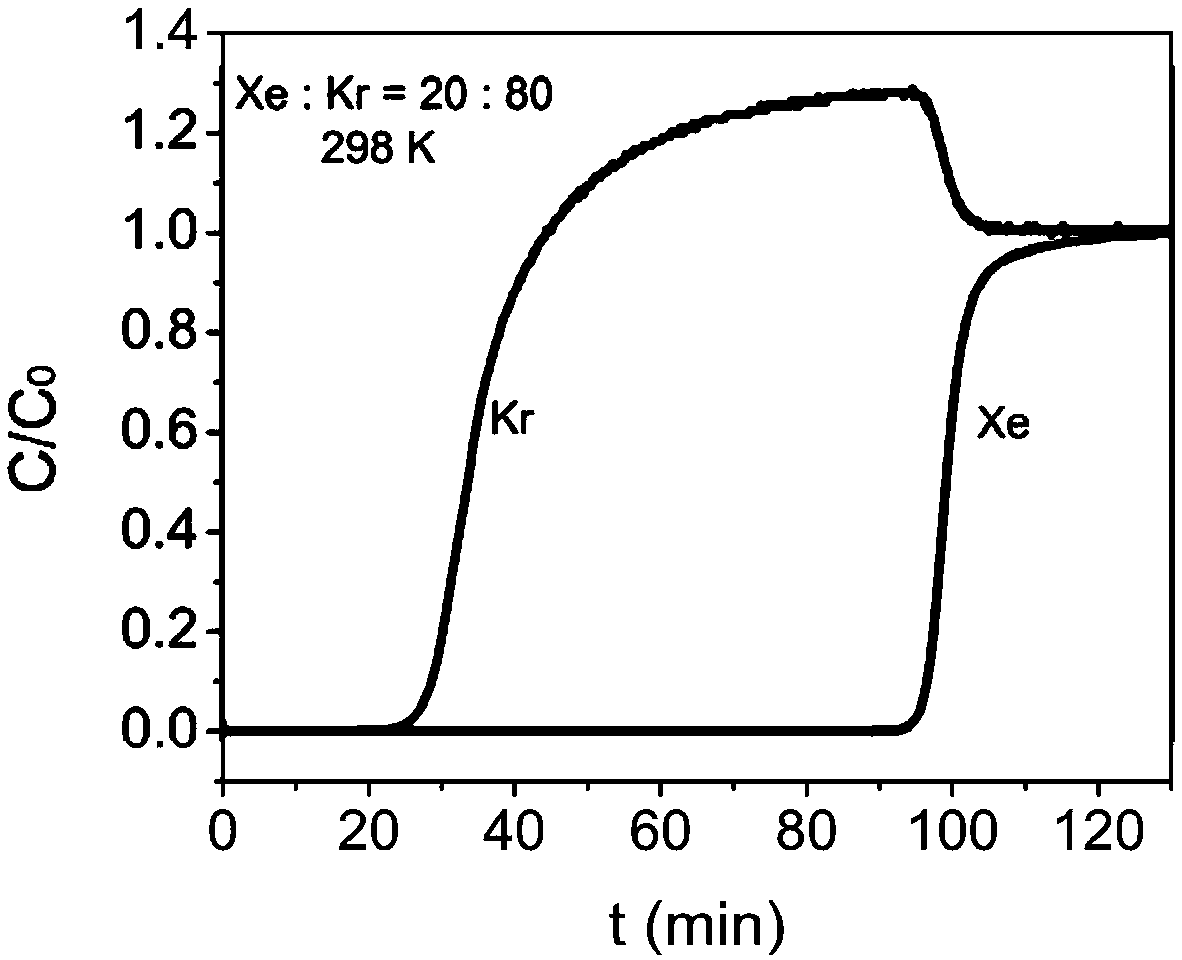

[0051] In order to test the adsorption-separation performance of the above-synthesized MOFs, single-component adsorption isotherms of xenon and krypton were carried out using the above-mentioned adsorbents. Take 100mg of adsorbent and set the adsorption temperature at 0°C and 25°C. After testing, at 0°C and 1 bar, the adsorption amount of xenon reaches 2.55mmol / g, and the adsorption amount of krypton is only 1.81mmol / g; at 25°C and 1bar, the adsorpti...

Embodiment 3

[0055] Mix 1.5mmol zinc acetate dihydrate, 1.5mmol 2,5-dihydroxy-1,4-benzoquinone, and 10mL deionized water, put them into a 25mL hydrothermal reaction kettle, and stir and react at room temperature for 12 hours. After the reaction is completed, the solid obtained from the reaction is centrifuged and washed several times with deionized water and ethanol to obtain a purified metal-organic framework material. The purified adsorbent was vacuum degassed at 100 °C for 12 h to obtain the desolvated adsorbent, followed by gas adsorption.

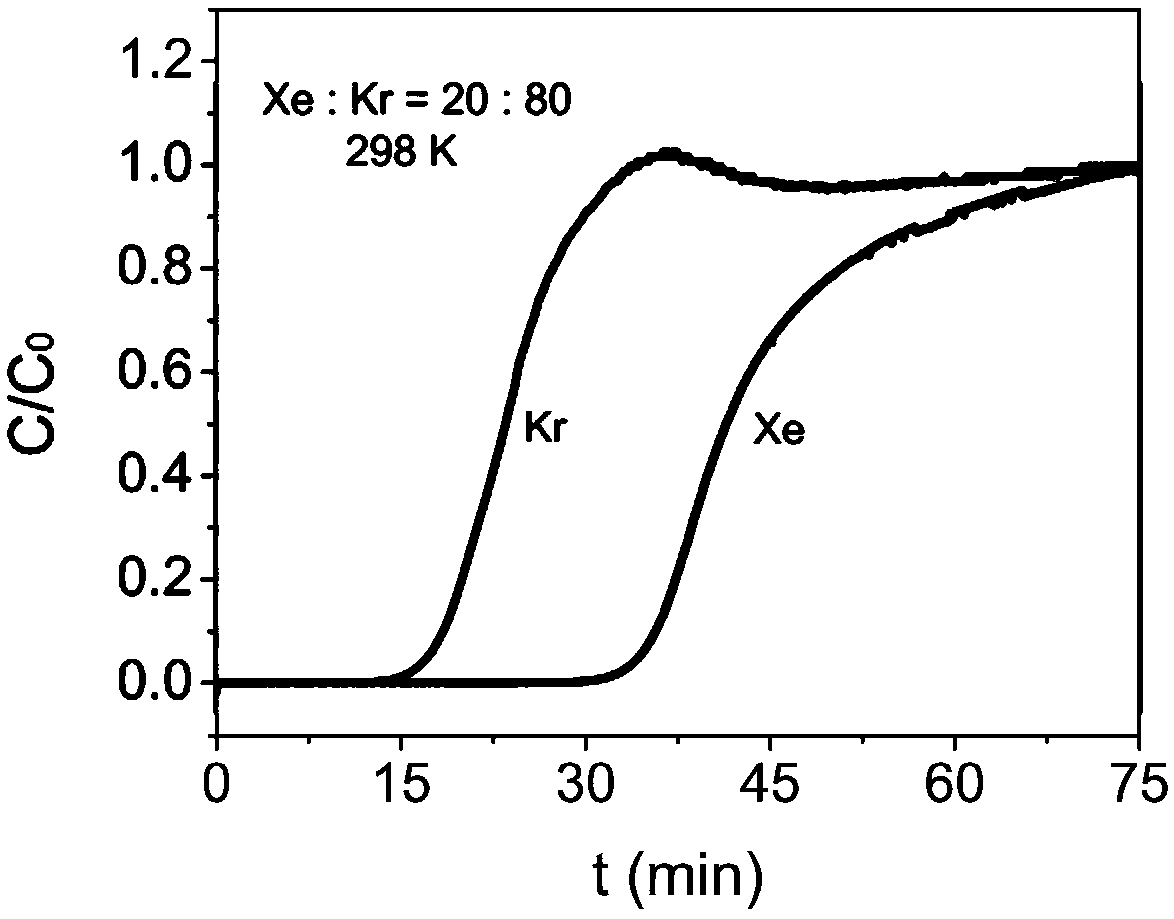

[0056] In order to test the adsorption-separation performance of the above-synthesized MOFs, single-component adsorption isotherms of xenon and krypton were carried out using the above-mentioned adsorbents. Take 100mg of adsorbent and set the adsorption temperature at 0°C and 25°C. After testing, at 0°C and 1 bar, the adsorption amount of xenon reaches 2.96mmol / g, and the adsorption amount of krypton is only 1.97mmol / g; at 25°C and 1bar, the adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com