Emulsified liquid mixing device for coal mine

A technology of emulsion and emulsion pump, which is applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of difficulty in mastering, poor emulsion precision, etc., and achieve the effect of improving automation level, ensuring concentration, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

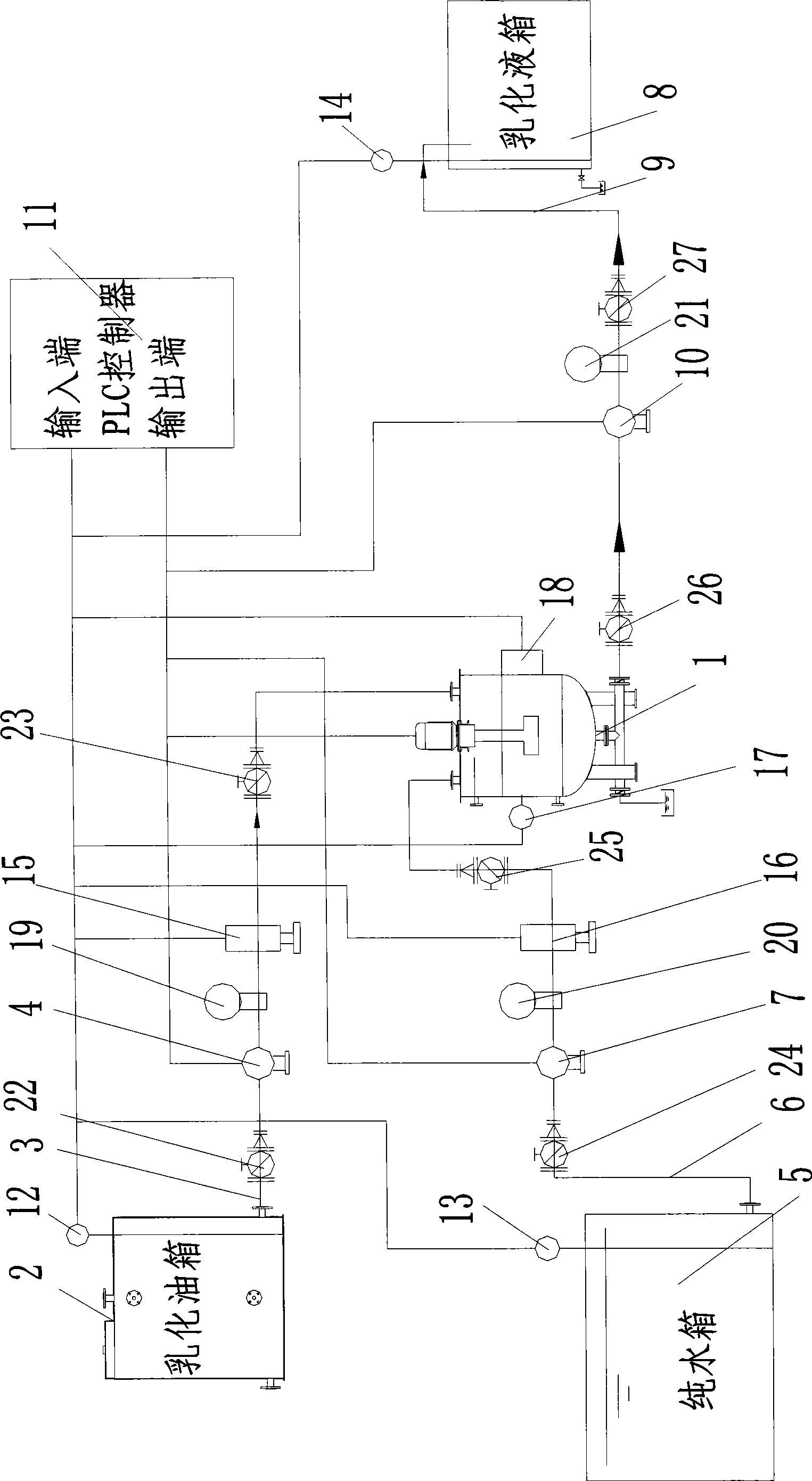

[0020] As shown in the figure, the present invention discloses an emulsion proportioning device for coal mines, which includes the following parts: emulsified oil distribution part, pure water distribution part, emulsifier 1, emulsion treatment part and PLC control part; the emulsified oil The distribution part and the pure water distribution part are communicated with the emulsifier input port for oil-water emulsification, and the output port of the emulsifier is communicated with the emulsion treatment part; the emulsified oil distribution part includes an emulsified oil tank 2, an emulsified oil delivery pipe 3 and Emulsified oil pump 4; the emulsified oil delivery pipe 3 communicates with the emulsified oil tank 2 and the emulsifier input port, and the emulsified oil pump 4 is arranged on the emulsified oil delivery pipe 3; the pure water distribution part includes a pure water tank 5, a pure water delivery Pipe 6 and pure water pump 7; the pure water delivery pipe 6 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com