Functional composite liquid fertilizer and preparation method thereof

A compound liquid, functional technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as unreasonable nutrient components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

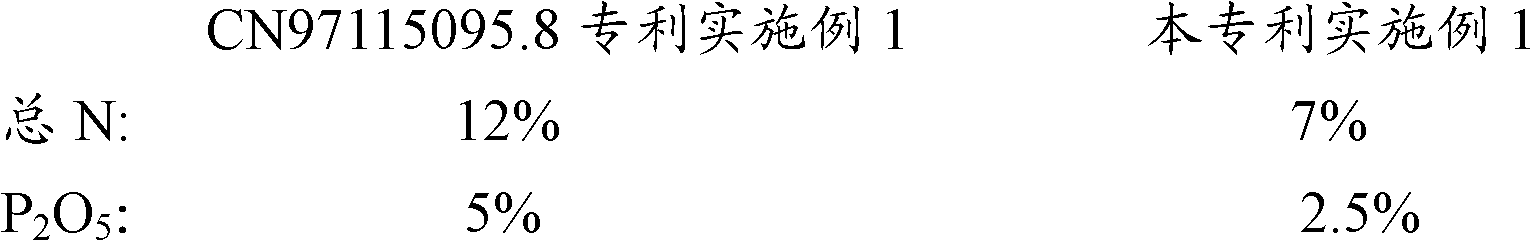

Embodiment 1

[0077] Embodiment 1: Preparation of functional compound liquid fertilizer of the present invention

[0078] After pulverizing 75 kilograms of hairtail and 75 kilograms of sea hemp shrimps with poor freshness, add 25 kilograms of sulfuric acid aqueous solution of 14% concentration, store for subsequent use after mixing.

[0079] Take the above mixture and put it into an acid-resistant pottery reaction kettle, put 134 kilograms of kelp after water has been pulverized into the kettle, add 30 kilograms of soybean meal powder, and slowly add citric acid, sulfuric acid, glacial acetic acid mixed aqueous solution (ratio 2:1:1) 250 kg, the total acid concentration (volume percentage) is 18%, react naturally for 30-50 minutes after stirring, then control the temperature to 80-90°C, and the hydrolysis time is 4-6 hours.

[0080] Cool the hydrolyzed solution to 40°C, then use 18 kg of potassium hydroxide to neutralize the pH value to 4, add 4.04 kg of activated carbon and 8.08 kg of pot...

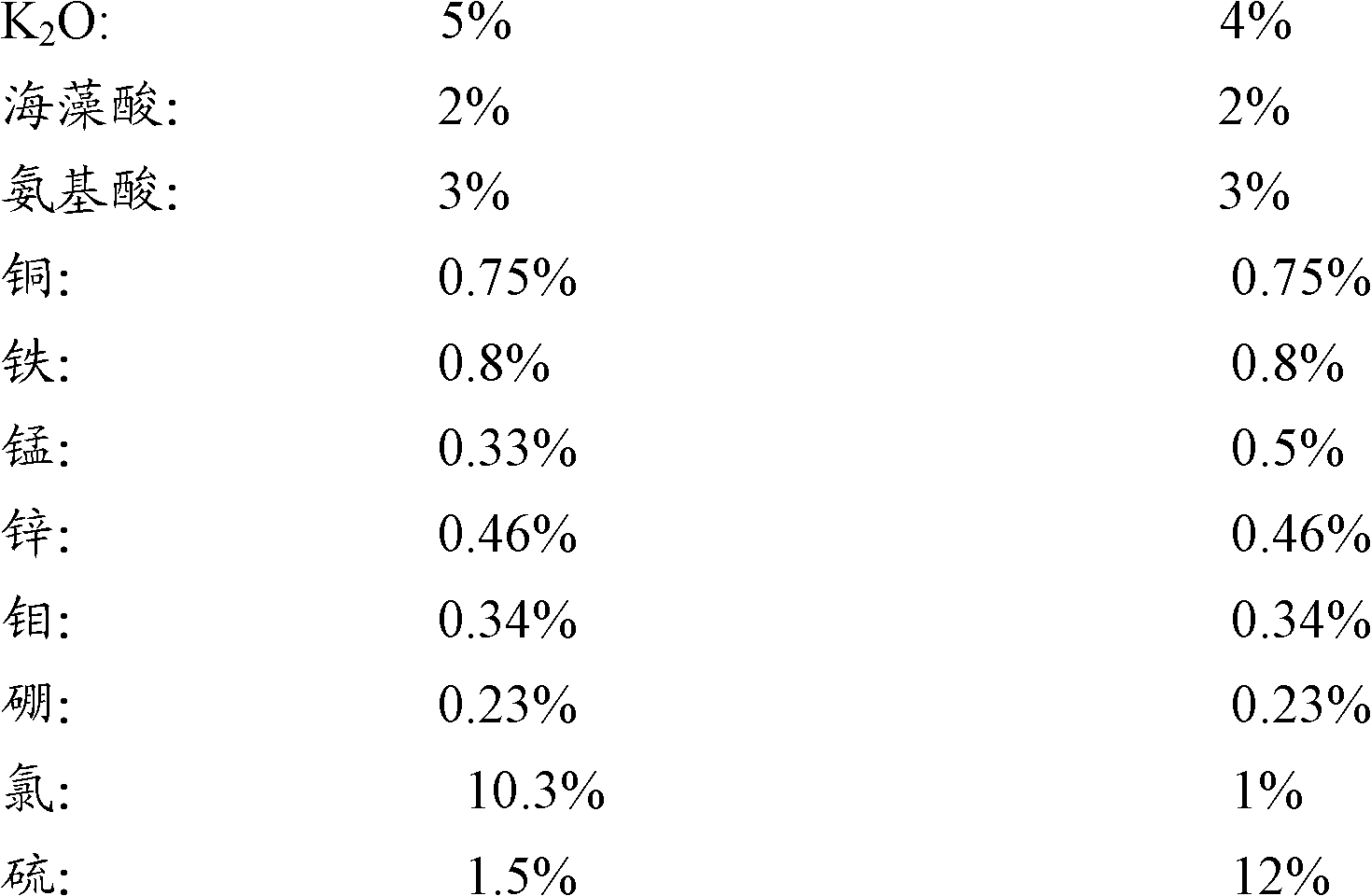

Embodiment 2

[0086] Embodiment 2: the preparation of functional compound liquid fertilizer of the present invention

[0087] After pulverizing 75 kilograms of hairtail and 75 kilograms of sea hemp shrimps with poor freshness, add 28 kilograms of sulfuric acid aqueous solution of 14% concentration, store for subsequent use after mixing.

[0088] Take the above mixture and put it into an acid-resistant pottery reaction kettle, put 134 kilograms of seaweed pulverized by water into the kettle, add 30 kilograms of rapeseed meal powder, and slowly add a mixed aqueous solution of citric acid, sulfuric acid, and glacial acetic acid (ratio 2:1:1 ) of 250 kilograms, the total acid concentration (volume percentage) is 18%, react naturally for 30-50 minutes after stirring, the temperature is controlled to 80-90 DEG C, and the hydrolysis time is 4-6 hours.

[0089] Cool the hydrolyzate to 40°C, then use 18 kg of potassium hydroxide to neutralize the pH value to 4, add 4.01 kg of activated carbon and 8....

Embodiment 3

[0094] Example 3: Verification of the effect of the functional compound liquid fertilizer of the present invention

[0095] This example verifies the fertilizer effect of the demonstration application of the functional compound liquid fertilizer of the present invention on tobacco.

[0096] 1. Test materials and methods

[0097] 1.1 Test time and place

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com