Method and device for detecting and controlling acetoacetic ester continuous reaction system on line

A technology of acetoacetate and reaction system, applied in the directions of measuring device, self-adaptive control, general control system, etc., can solve the problems of cumbersome operation, small production scale of a single batch reaction device, and low yield of acetoacetate product. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

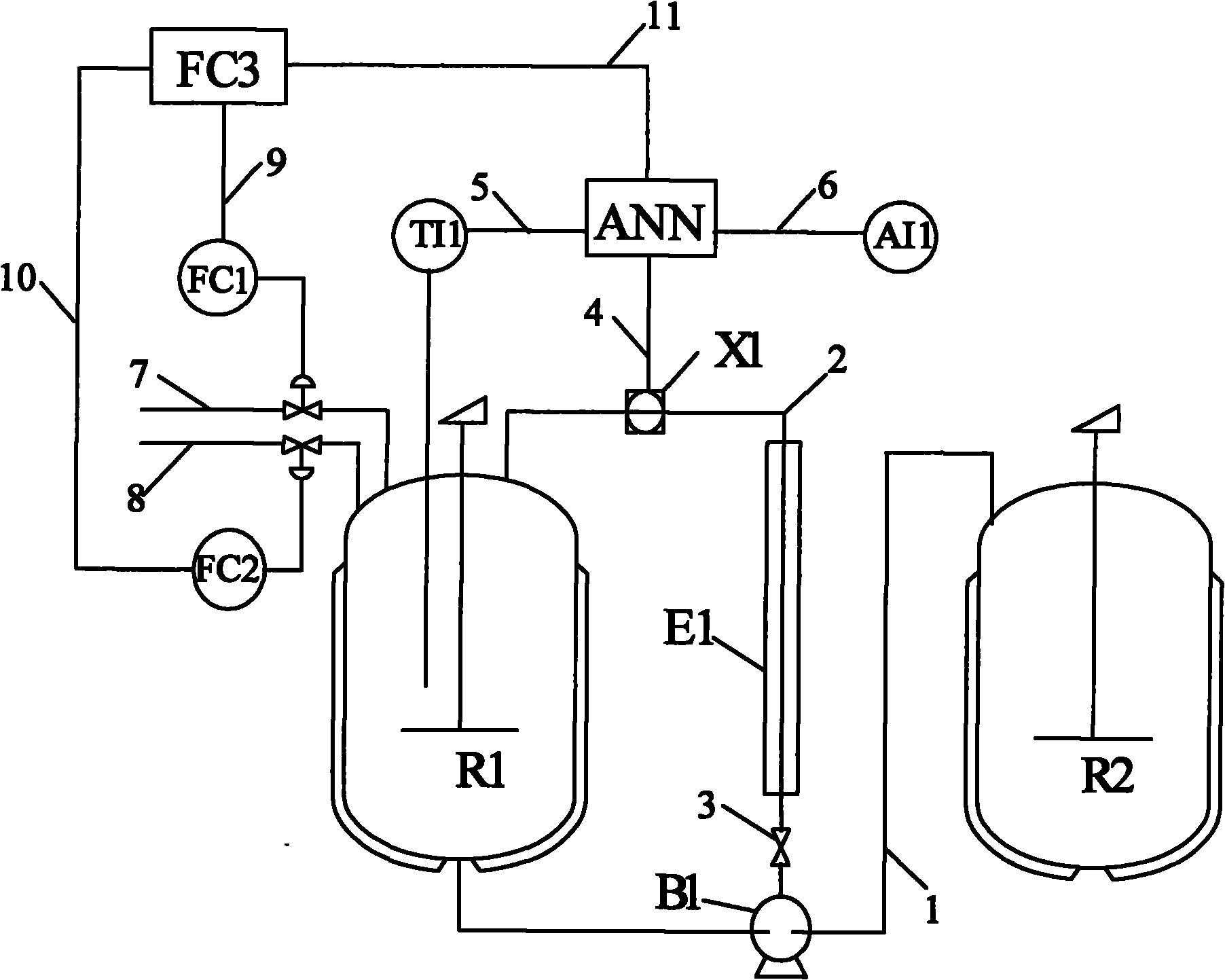

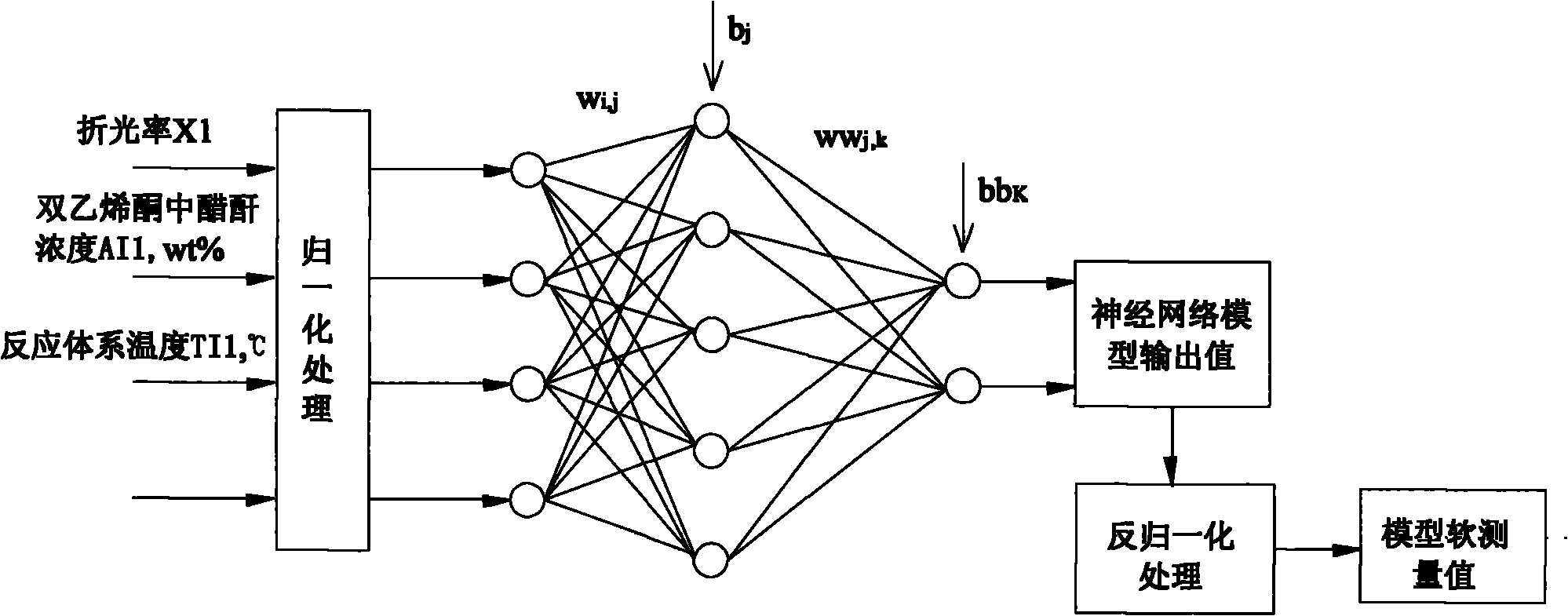

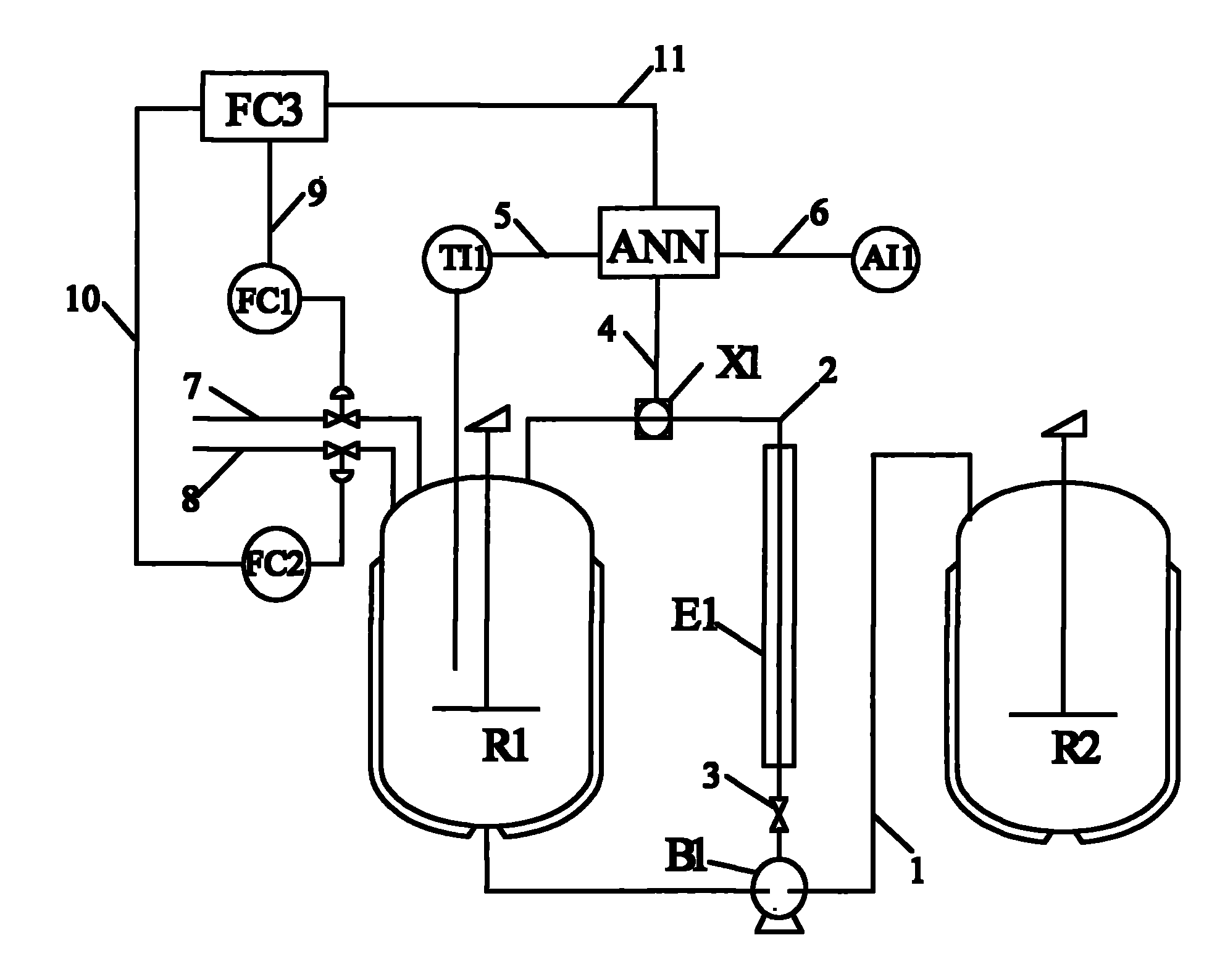

[0045] The on-line detection and control device of the acetoacetate continuous reaction system of the present invention, such as figure 1 As shown, it includes reactor R1, aging flash tank R2 and neural network soft sensor model controller ANN, the discharge port of reactor R1 is connected with the feed port of aging flash tank R2 through the first pipeline 1, the first A pipeline 1 is equipped with a circulation pump B1, and the circulation pump B1 is also equipped with a circulation pipeline 2 connected to the reactor R1. The circulation pipeline 2 is equipped with a valve 3, a cooler E1 and an online refractometer X1. The online refractometer X1 is connected with the neural network soft-sensing model controller ANN, and a temperature detector TI1 is also provided on the reactor R1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com