Multi-station rhinestone slant grinding and polishing machine

A grinding and polishing machine, multi-station technology, applied to grinding/polishing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve problems such as unfavorable transportation and use, large volume, and reduced operating time, and achieve Ensure equipment utilization and processing efficiency, reduce machine volume and occupied space, facilitate transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

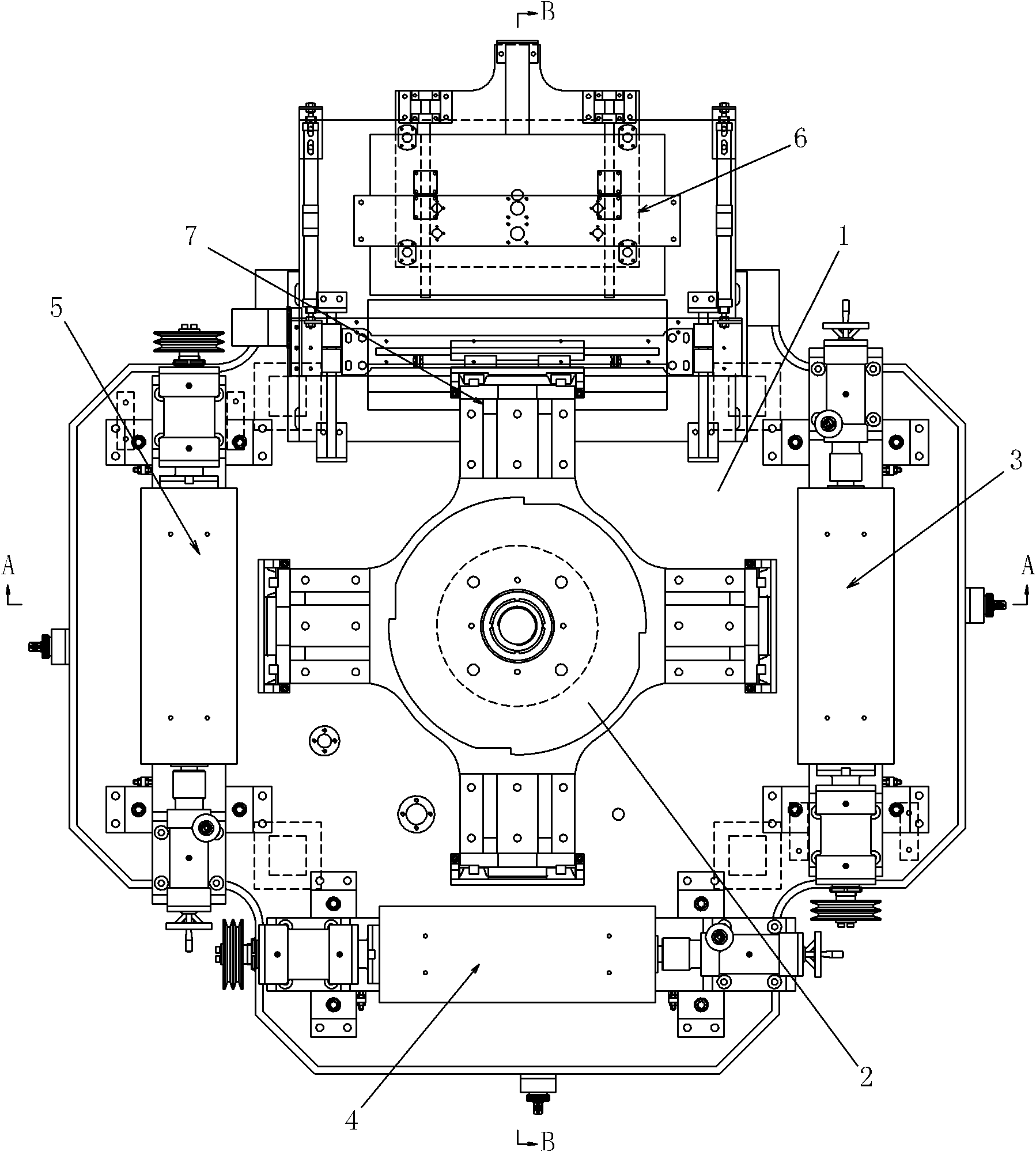

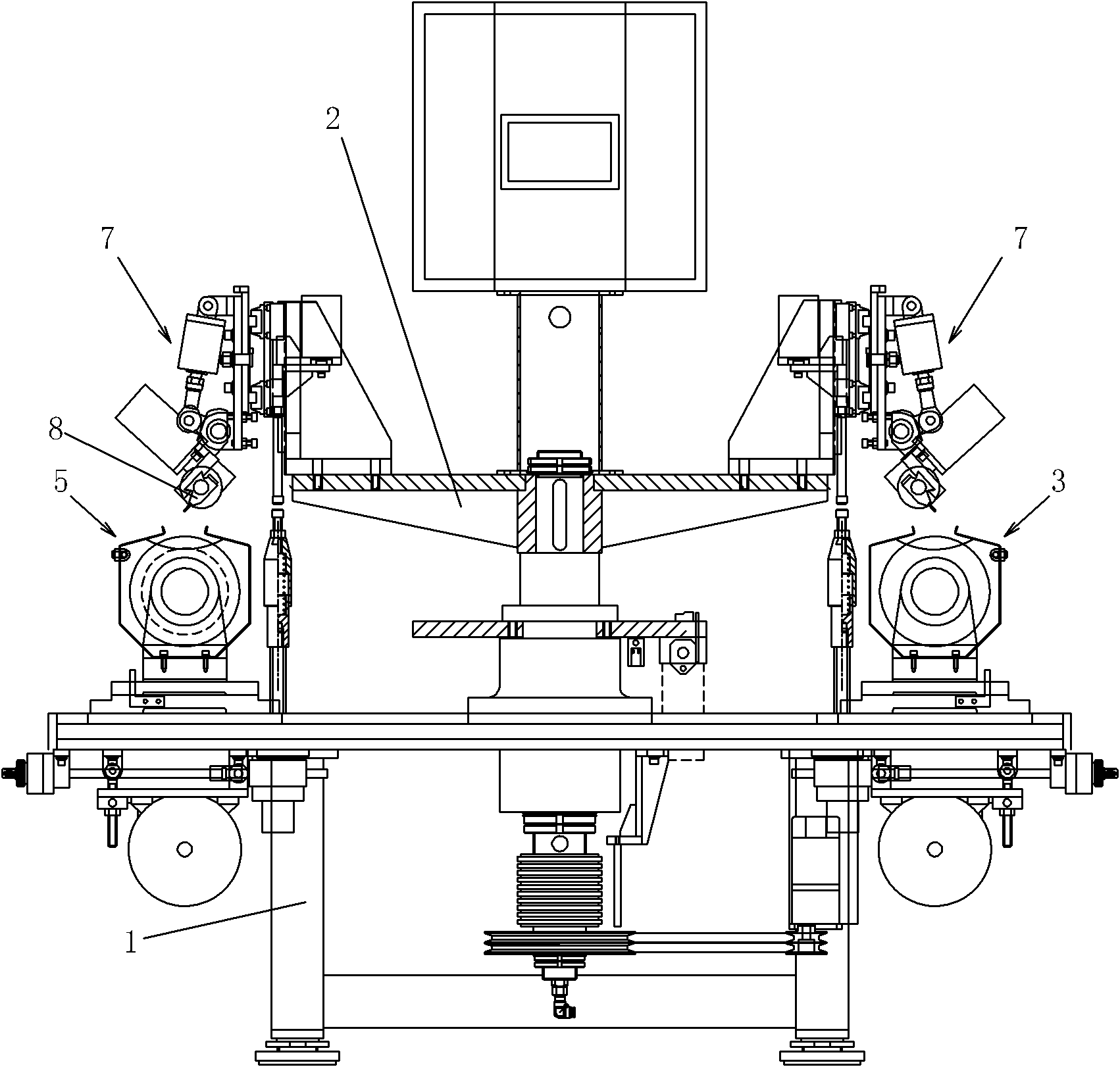

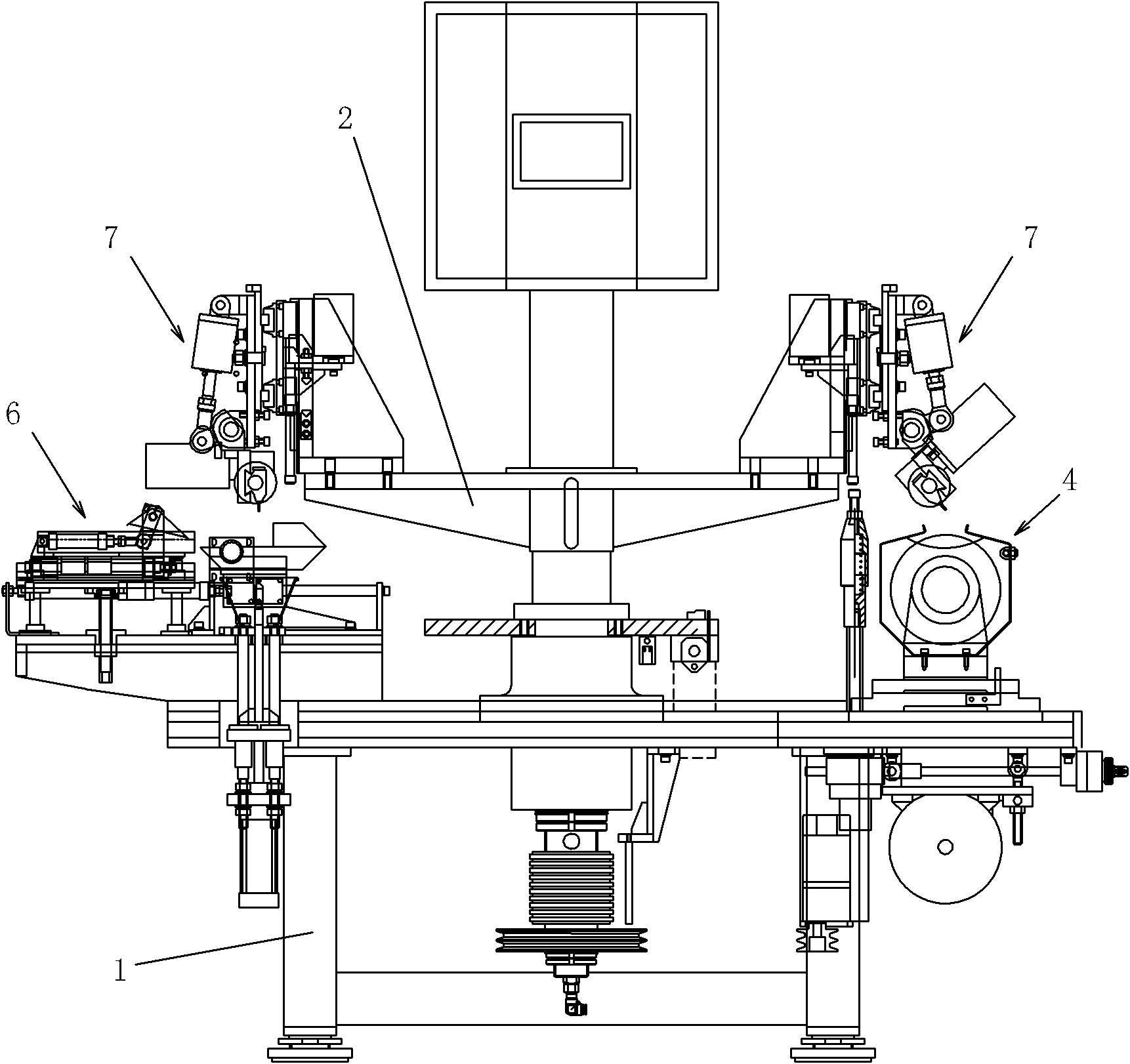

[0022] Such as figure 1 , figure 2 , image 3 The shown multi-station rhinestone end face grinding and polishing machine includes a frame 1, a rotating frame 2 is arranged on the frame 1, a plurality of machine heads 7 are arranged on the rotating frame 2, and a rhinestone fixture is arranged on the machine head 7 8. The frame 1 is provided with a loading and unloading station 6, a grinding station 5 and a polishing station 3, 4 corresponding to the plurality of machine heads 7, and the loading and unloading station 6 is provided with There is an automatic loading and unloading mechanism, the grinding station 5 is provided with a grinding mechanism, and the polishing stations 3 and 4 are provided with a polishing mechanism.

[0023] Such as Figure 4 , Figure 5 As shown, the automatic loading and unloading mechanism includes a mounting seat 606 installed on the frame 1, and the mounting seat 606 is provided with a pushing device, a powder feeding device, a material recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com