Method for controlling suction and abutment system for fully-automatic cutting machine of radial tyre fiber cord fabric

A control method and technology of radial tires, applied to tires, metal processing, and other household appliances, can solve problems such as absolute coordinate value deviation, deviation, and large running deviation of the main conveyor belt, and achieve simple maintenance and repair, and accurate absorption The effect of docking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

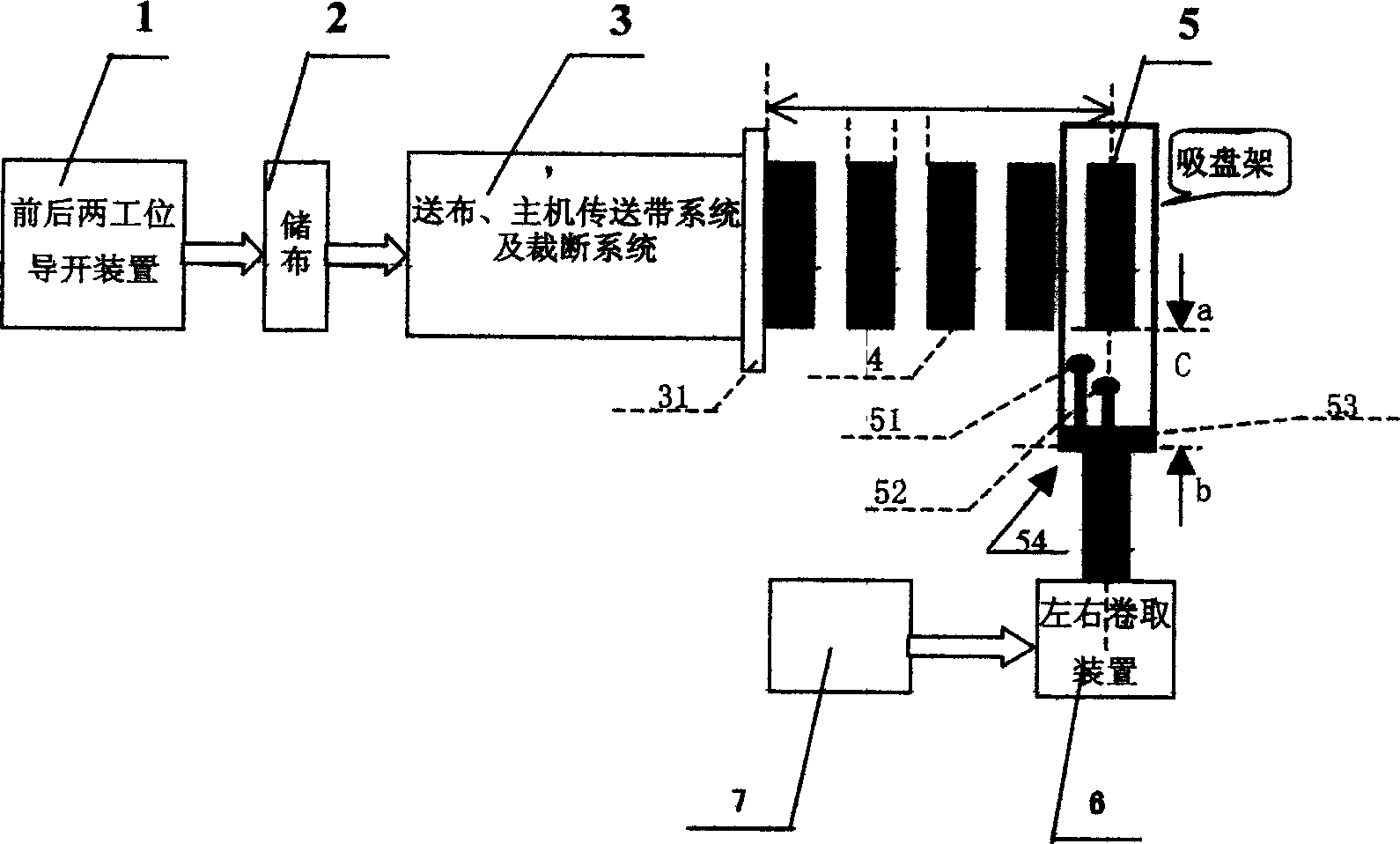

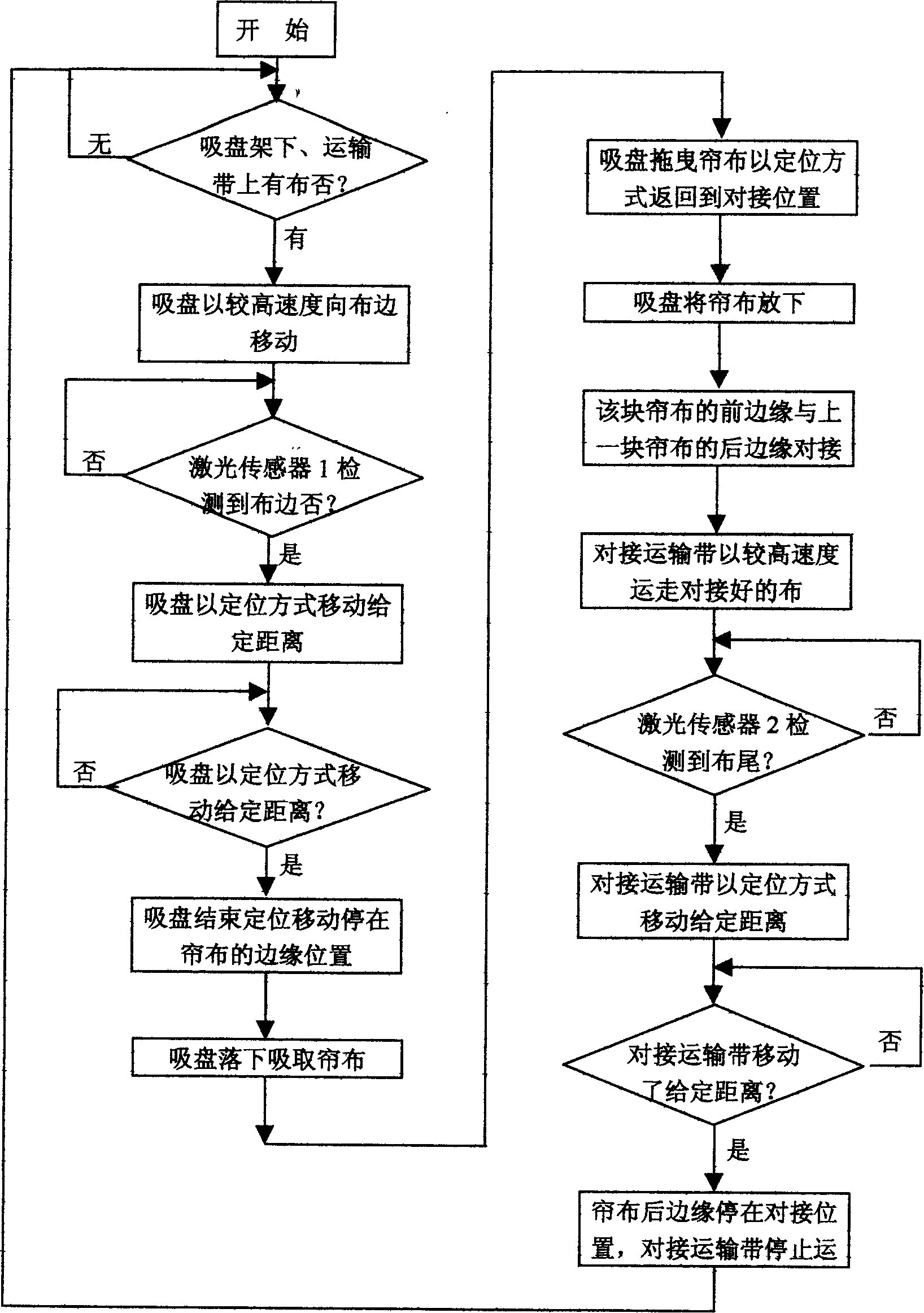

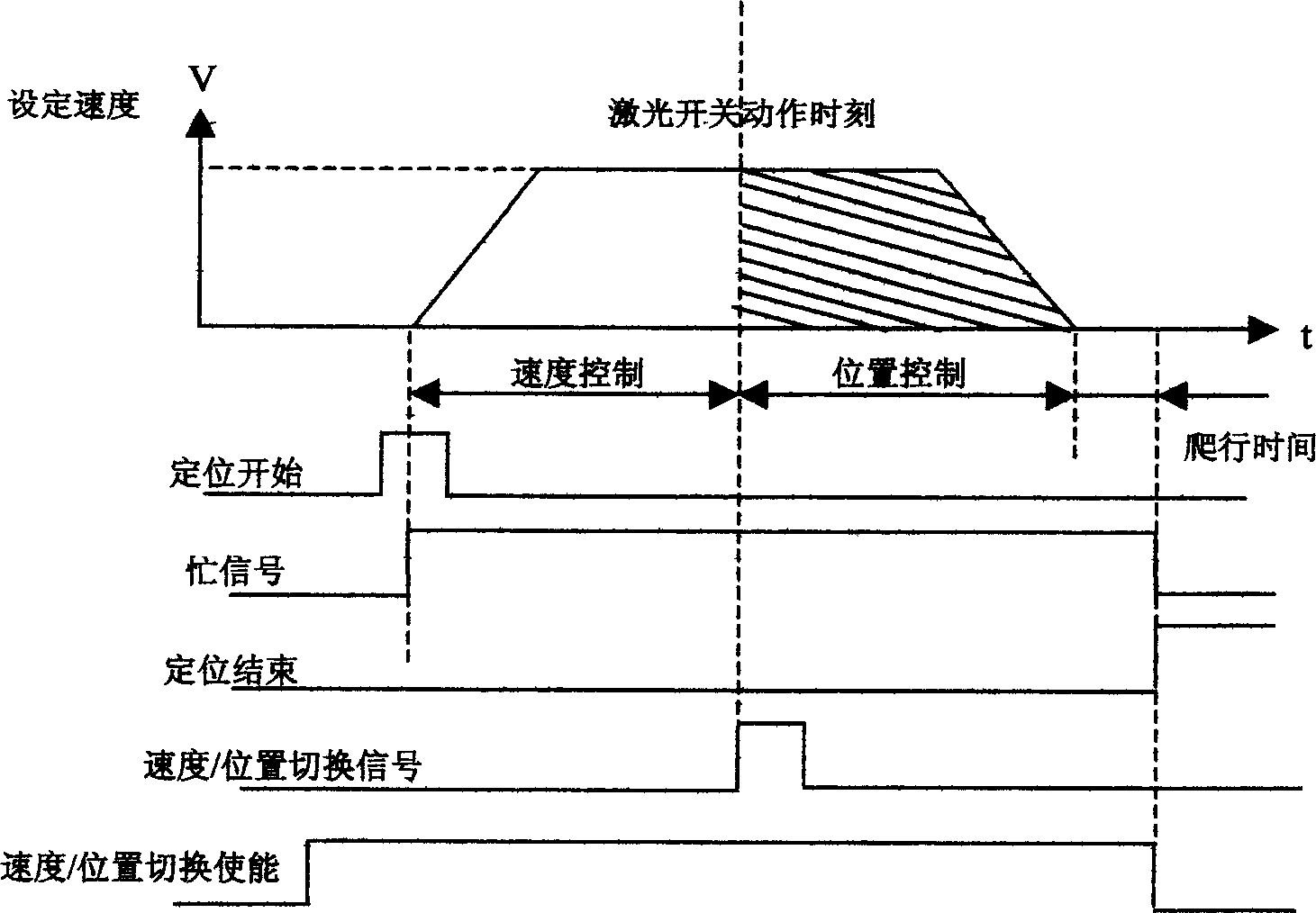

[0016] Depend on Figure 1A , Figure 1B It shows the main components of the suction and docking system of the present invention and the key points of its control method, that is, a control method for the suction and docking system of a radial tire fiber cord automatic cutting machine. The system is mainly composed of a guide device 1, storage The cloth device 2, the conveying and cutting device 3, the cord 4, the suction cup frame 5, the suction and docking dragging device 6, and the control equipment 7 of the suction and docking device, wherein: the control method of the suction and docking system is the suction cup frame 5 When there is a cord 4 on the main conveyor belt below, the photoelectric switch 51 acts, and the suction cup 53 and the laser sensor start to move toward the cord 4 at a speed from the butt line b; The servo motor runs to the appropriate position in the position mode and stops; the suction cup 53 absorbs the cord 4 and returns to the docking line b in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com