Optical fiber cutting device

A cutting equipment and optical fiber technology, applied in the field of optical communication, can solve problems such as low pass rate, inconvenient on-site use, and impact on the quality of on-site splicing, and achieve the effect of ensuring cutting efficiency and cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

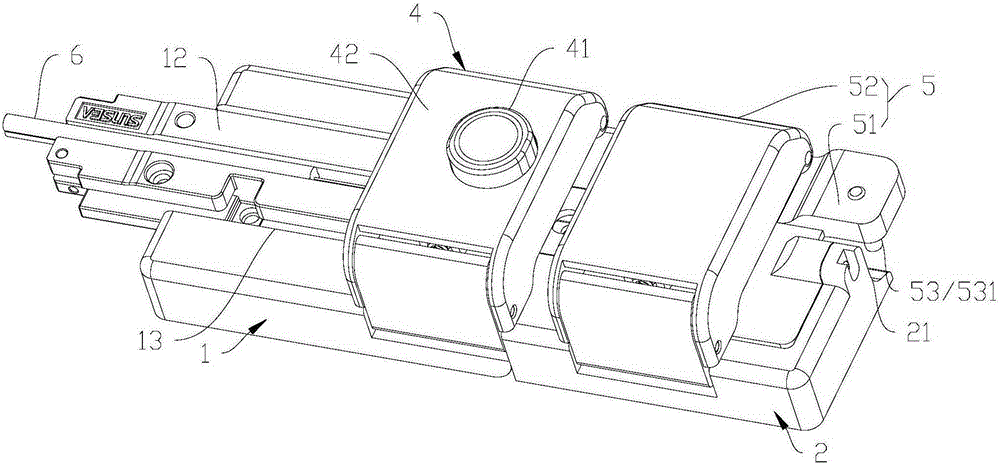

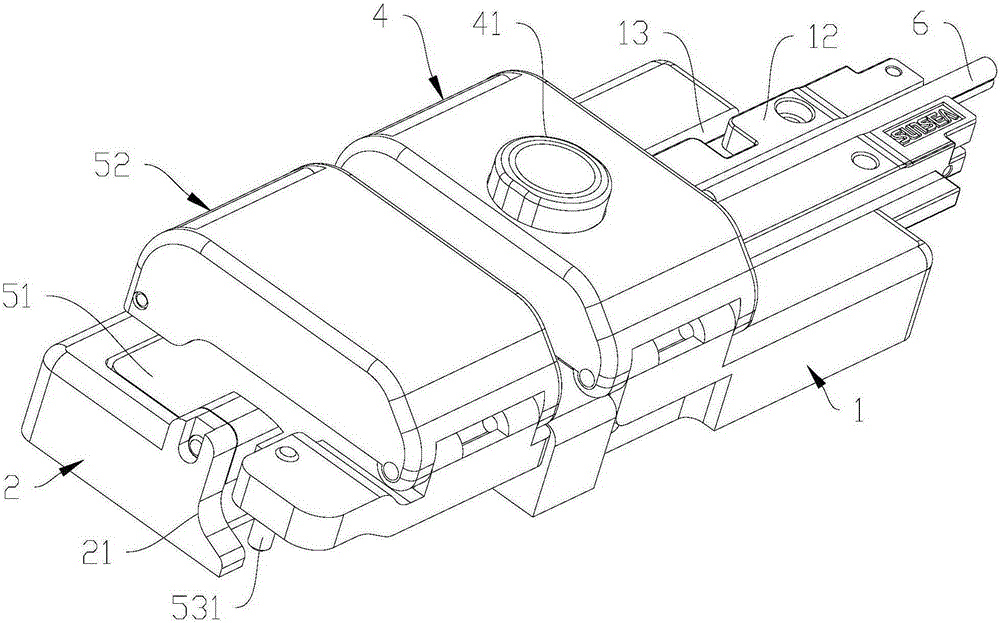

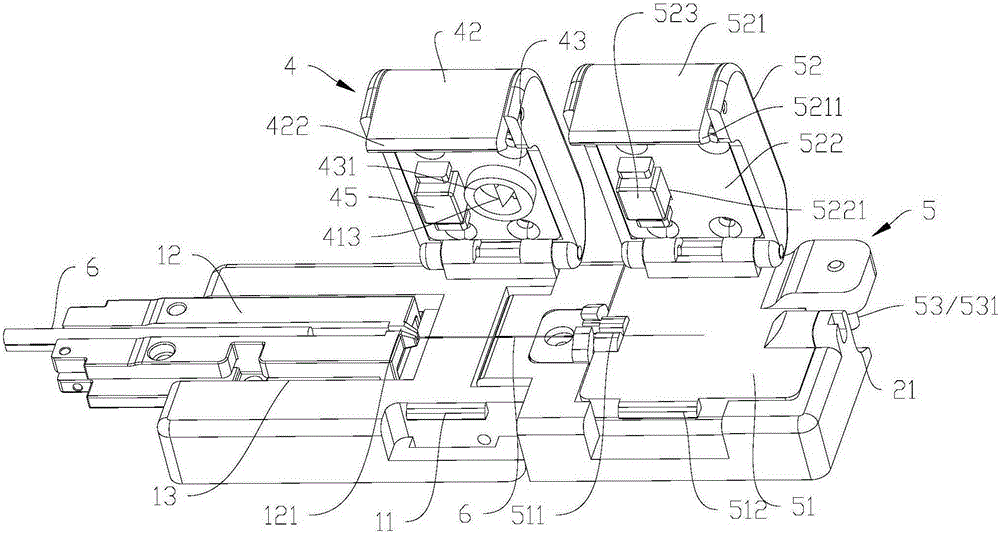

[0045] like Figure 1 to Figure 3 As shown, the optical fiber cutting device in a preferred embodiment of the present invention includes a base 1 , a rotating base 2 , a holding mechanism 3 , a first clamping unit 4 , a cutter assembly 41 and a second clamping unit 5 . One end of the base 1 and one end of the rotating base 2 are hinged to each other, so that the longitudinal ends of the optical fiber 6 to be cut are placed on the base 1 and the rotating base 2 respectively. The holding mechanism 3 is arranged between the base 1 and the rotating base 2 , and provides an active force to keep the rotating base 2 and the base 1 flush. The first clamping unit 4 is arranged on the base 1 to fix the corresponding position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com