Laser cutting method

A laser cutting and cutting head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of rising management costs, low cutting efficiency, high requirements for operating skills, etc., and achieve high positioning accuracy and motion positioning accuracy , Guarantee cutting efficiency and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be made below in conjunction with the preferred embodiment shown in each accompanying drawing.

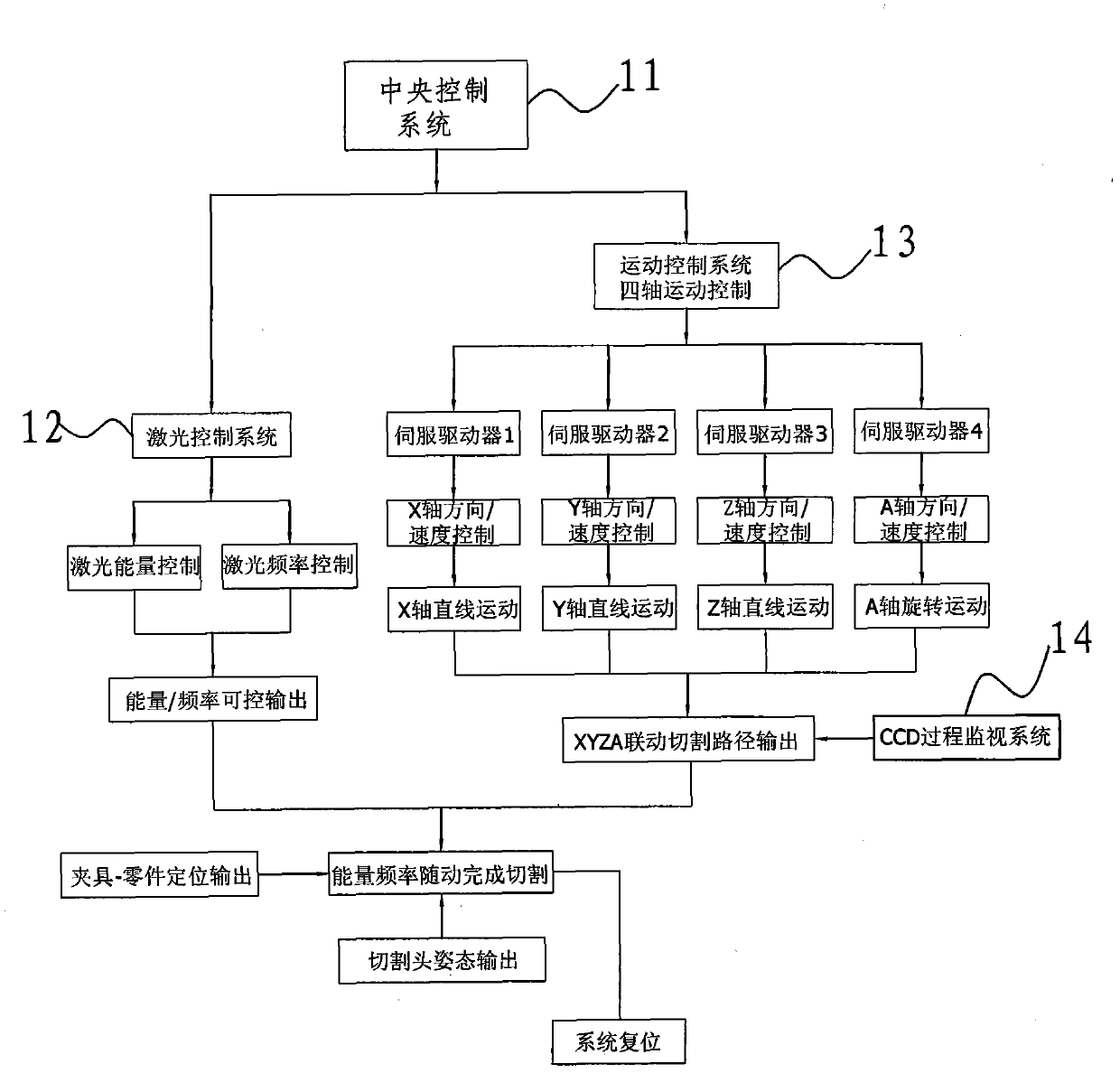

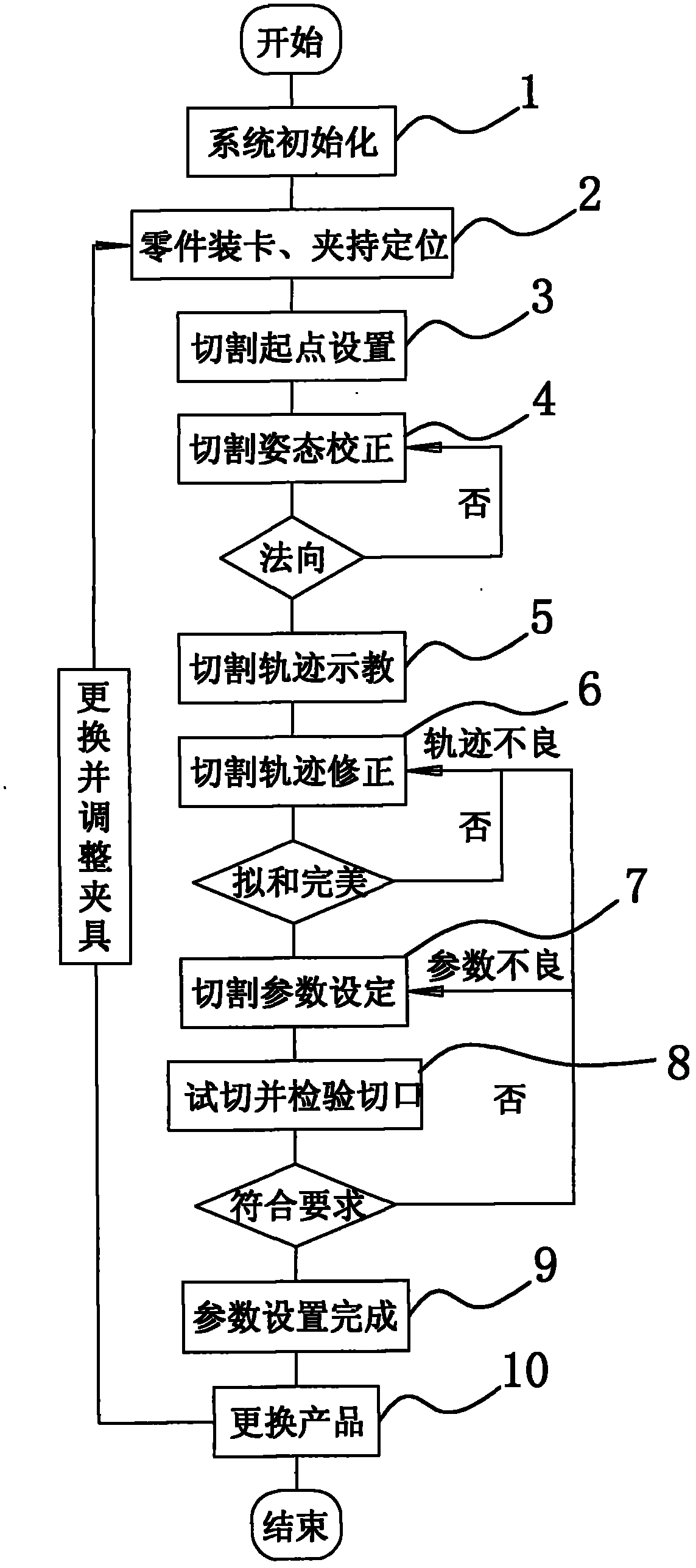

[0030] The present invention relates to a kind of laser cutting method, the implementation of this method needs to mention a kind of system combination, such as figure 1 , the system combination includes: a multi-axis linkage workbench, a laser cutting machine, and a CCD process monitoring system 14, wherein the process of the entire method requires a central control system 11 to adjust and control the motion control system 13 of the cutting path of the workbench, and control the laser cutting machine. The energy and frequency laser control system 12 and the program control software for executing each system; in this embodiment, the laser cutting is a CO2 laser cutting machine.

[0031] like figure 1 In the described embodiment, the multi-axis linkage workbench is an XYZ-A four-axis linkage workbench, and the linear motion speeds in the X, Y, Z, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com