Large-sized glass fiber reinforced plastic shaping mold, as well as manufacturing equipment and manufacturing method thereof

A glass fiber reinforced plastic tank and manufacturing equipment technology, applied in the field of glass fiber reinforced plastic molding, can solve the problems of low connection strength between reinforcing ribs and tank body, affecting the overall strength of the glass fiber reinforced plastic tank body, complex molding process, etc., to achieve high strength and avoid extrusion deformation or damage. , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

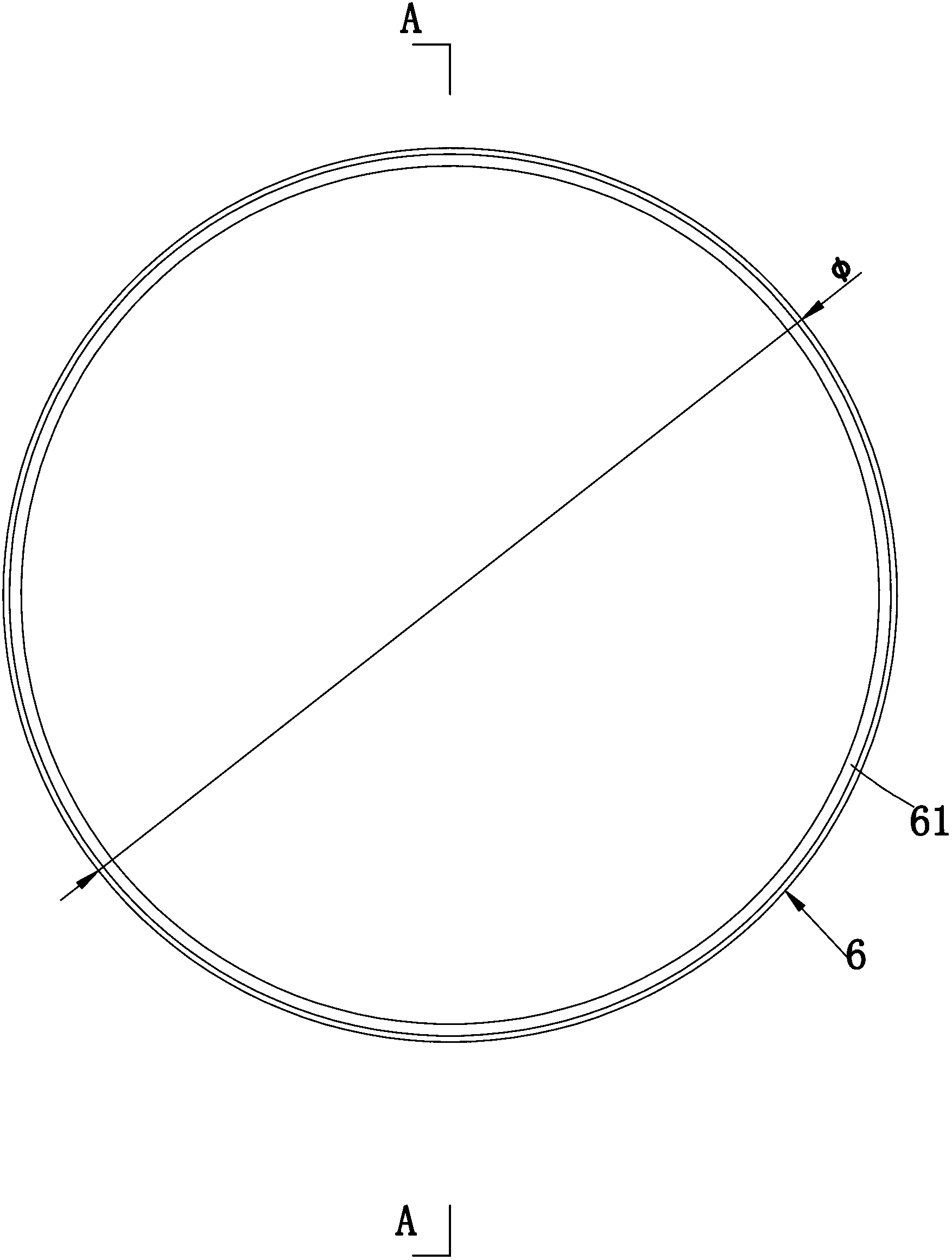

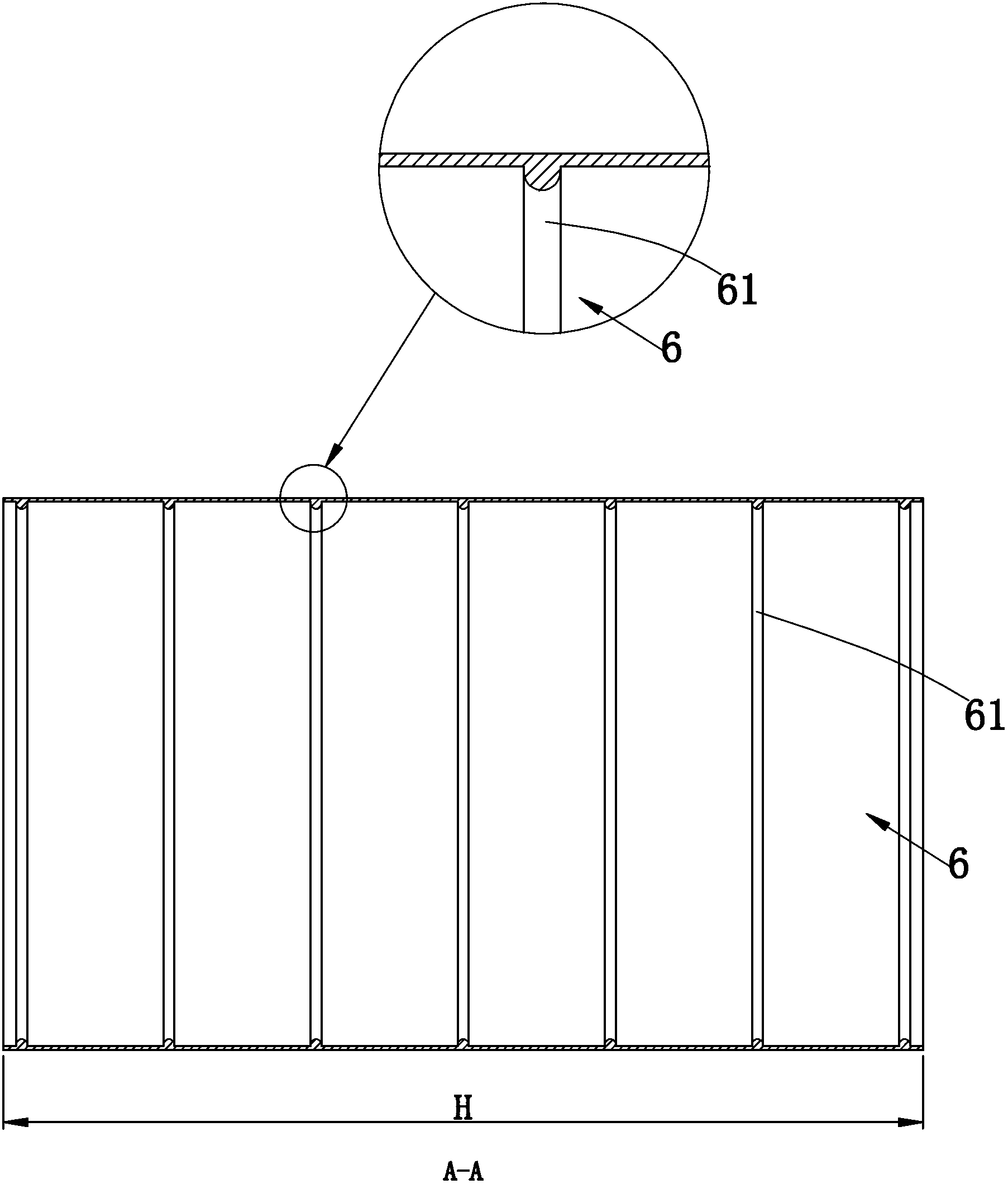

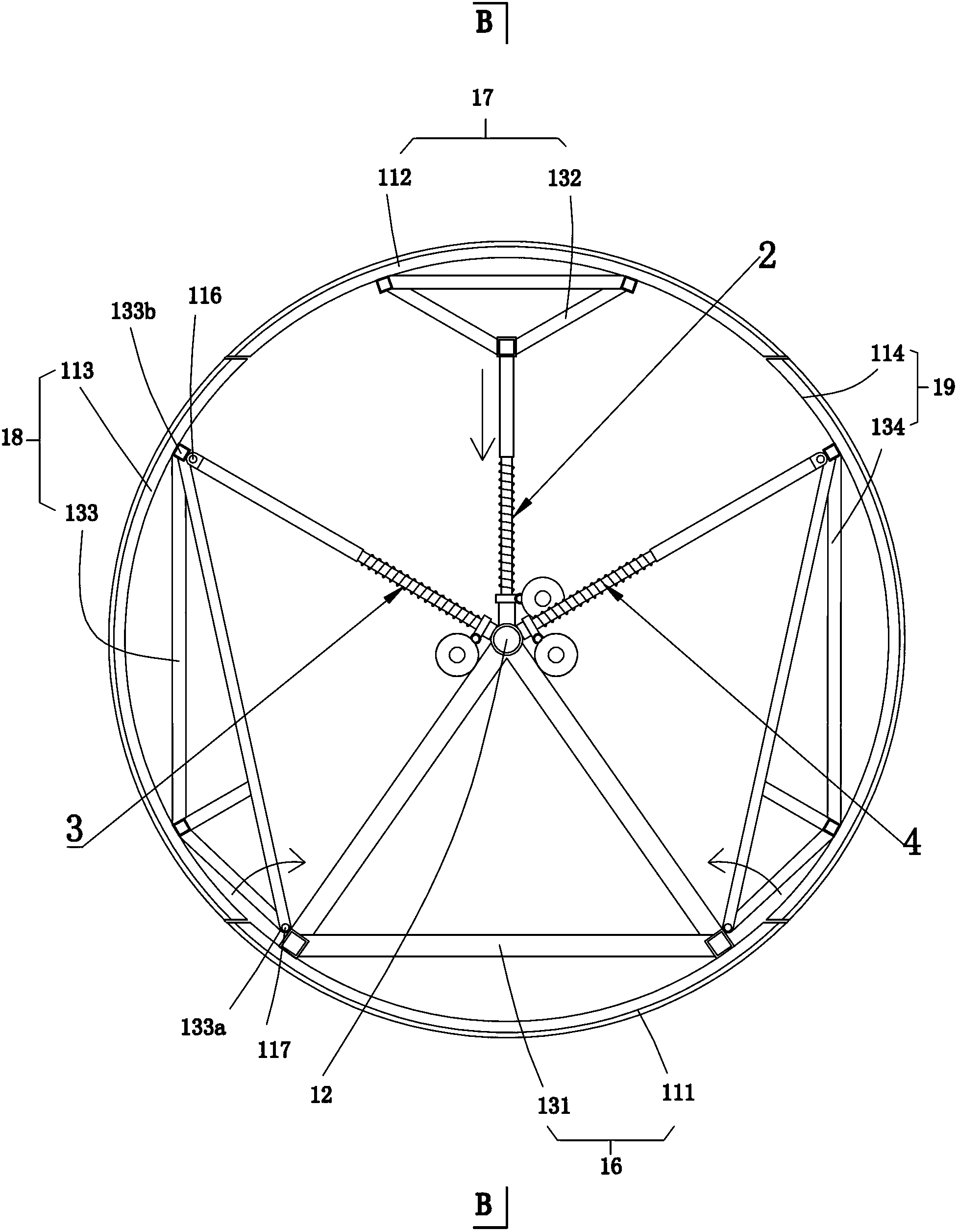

[0043] Such as Figure 3 to Figure 5 As shown, the mold 1 of the embodiment of the present invention is used to manufacture such as Figure 1 to Figure 2 The shown straight cylindrical large-scale glass-steel tank body 6 is in the shape of a cylinder but is not limited to a cylinder shape. The diameter Φ of the tank body 6 is generally greater than 1 meter, the maximum diameter can reach 5 meters, and the length H is generally The diameter of the tank body 6 produced by the mold 1 of the present embodiment is 3 meters, and the diameter of the tank body 6 changes accordingly, and the size of the mold 1 also changes accordingly. The inner wall of the tank body 6 is axially provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com