Slab ballastless track self-compacting concrete pouring construction method

A self-compacting concrete, slab ballastless track technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of air bubbles being difficult to discharge, and the quality of concrete pouring cannot be guaranteed, so as to ensure construction quality, high construction efficiency, and guarantee The effect of perfusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

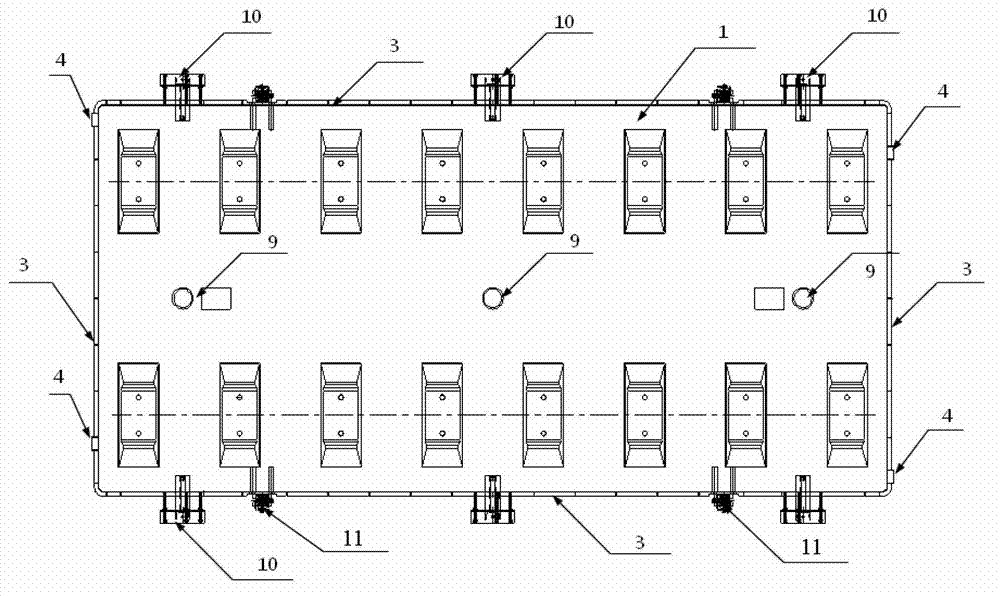

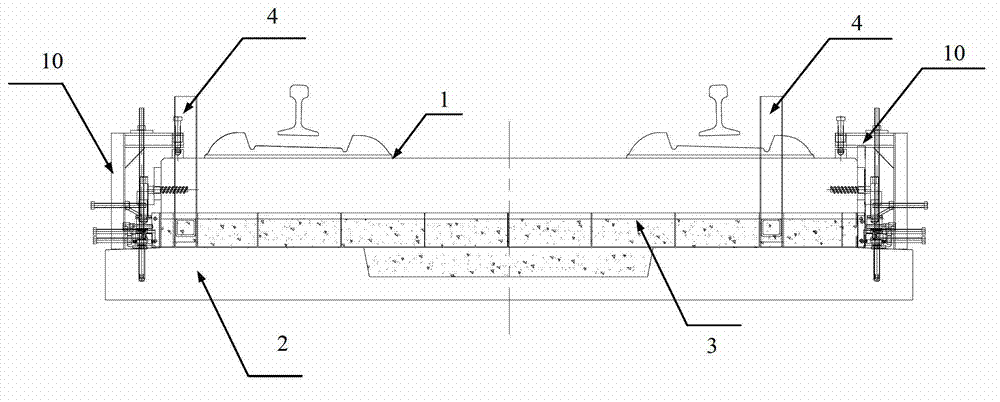

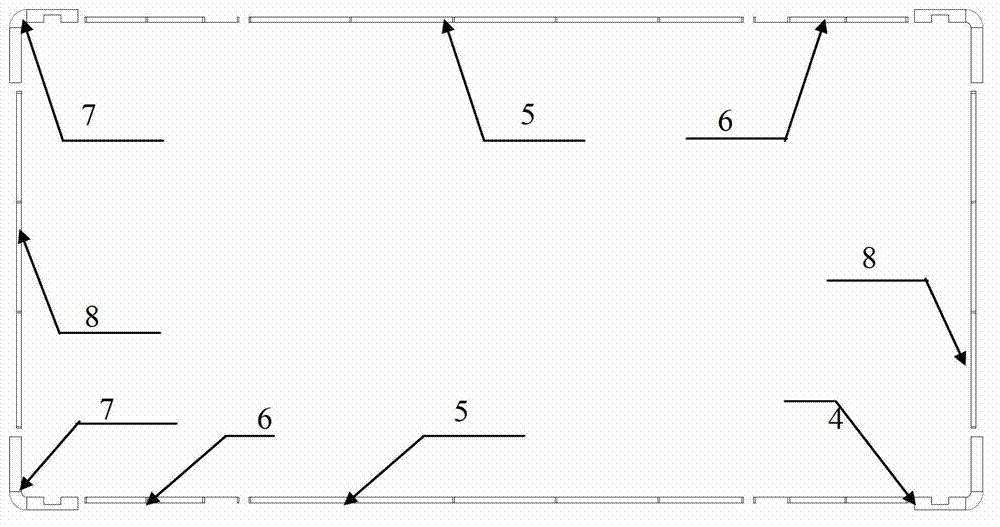

[0032] This example proposes a self-compacting concrete pouring method for CRTSIII slab ballastless track, and the tooling used mainly includes pouring hoppers, composite formwork, track slab bidirectional limit devices, and track slab fine adjusters. Fill the self-compacting concrete from the pouring hole 9 reserved in the middle of the CRTS III track plate 1, observe the flow velocity of the self-compacting concrete from the reserved holes on both sides, and control the pouring speed of the pouring hopper. When the self-compacting concrete is poured into the plate cavity from the reserved hole in the middle of the track slab and spreads around, because the composite formwork has four special vent holes, the air in the track slab can be effectively removed, and at the same time Observe whether the self-compacting concrete reaches the four corners through the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com