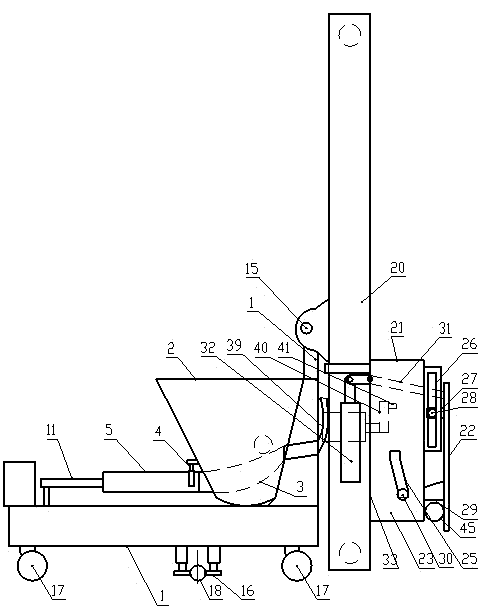

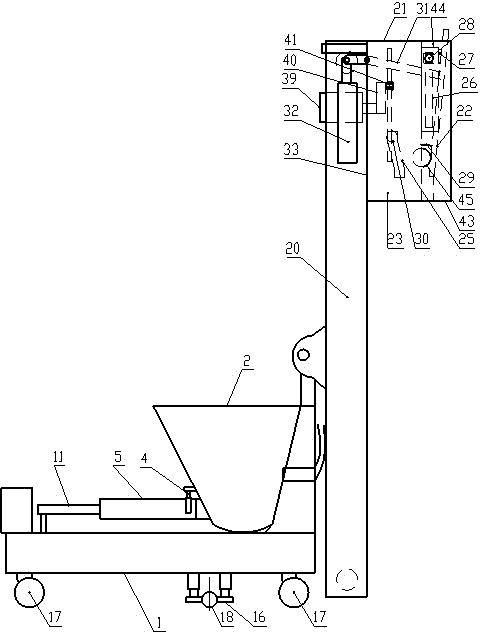

Automatic wall plastering machine

A wall plastering machine, automatic technology, applied in the direction of construction, building construction, etc., can solve the problems of plastering quality influence, the distance between the wiper and the wall, time-consuming and labor-intensive problems, etc., to achieve the guarantee effect, wall flatness and wall surface The effect of quality improvement, quality assurance and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

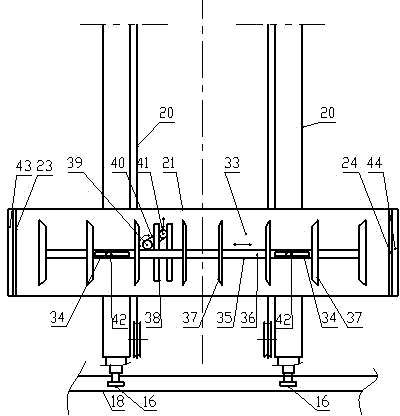

[0046] Such as Figure 7 As shown, the swing cylinder inlet 6 is connected with the swing mechanism 4, the swing mechanism 4 includes a swing rod 12 and two second hydraulic cylinders 13, the rear side of the hopper 2 is connected with a swing shaft 46, and the upper end of the swing rod 12 is connected with the swing shaft 46. The hopper 2 is rotatably connected, and the lower end of the swing rod 12 is fixedly connected with the swing cylinder inlet 7 . The swing cylinder outlet 7 and the swing shaft 46 are rotatably connected to the front and rear sides of the hopper 2, and the centerlines of the swing cylinder outlet 7 and the swing shaft 46 coincide. The swing shaft 46 and the connection between the swing cylinder outlet 7 and the hopper 2 are all provided with bearings.

[0047] The upper end of the swing lever 12 is integrally connected with a push rod 51, the push rod 51 coincides with the center line of the swing rod 12, and the both sides of the push rod 51 are resp...

Embodiment approach 2

[0050] Since the swing rod 12 adopted in the first embodiment initially has an included angle when it swings to both ends, and the force is not good, the second embodiment can be adopted.

[0051] Such as Figure 8 As shown, the swing mechanism 4 cancels the two second hydraulic cylinders 13, the hydraulic motor 47 replaces the second hydraulic cylinder 13 to provide power, the swing shaft 46 is reserved, the swing rod 12 retains a section connected to the swing cylinder 3, and the lower end of the swing rod 12 It is connected to the end of the swing cylinder 3, and the upper end of the swing rod 12 is rotationally connected to the swing shaft 46. The difference is that the swing mechanism 4 includes a hydraulic motor 47, an active reversing wheel 48, a passive reversing wheel 49, and two traction ropes 50. The hydraulic motor 47 is equipped with an active reversing wheel 48, the upper end of the swing lever 12 is coaxially connected with the passive reversing wheel 49, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com