Energy-saving glue preparation device for silica gel belt production

A silicone tape and glue dispensing technology, which is applied in the field of energy-saving glue dispensing devices for the production of silica gel belts, can solve the problems of poor tape molding quality, smooth glue distribution and application, and low environmental protection, so as to prevent the mixing of air bubbles and impurities, glue Uniform distribution of liquid and the effect of ensuring thermal fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be noted that the embodiments of the present invention and the features in the embodiments may be combined with each other under the condition of no conflict.

[0038] It is understood that these descriptions are exemplary only and are not intended to limit the scope of the invention.

[0039] The following describes an energy-saving glue dispensing device for producing a silicone tape provided by some embodiments of the present invention with reference to the accompanying drawings.

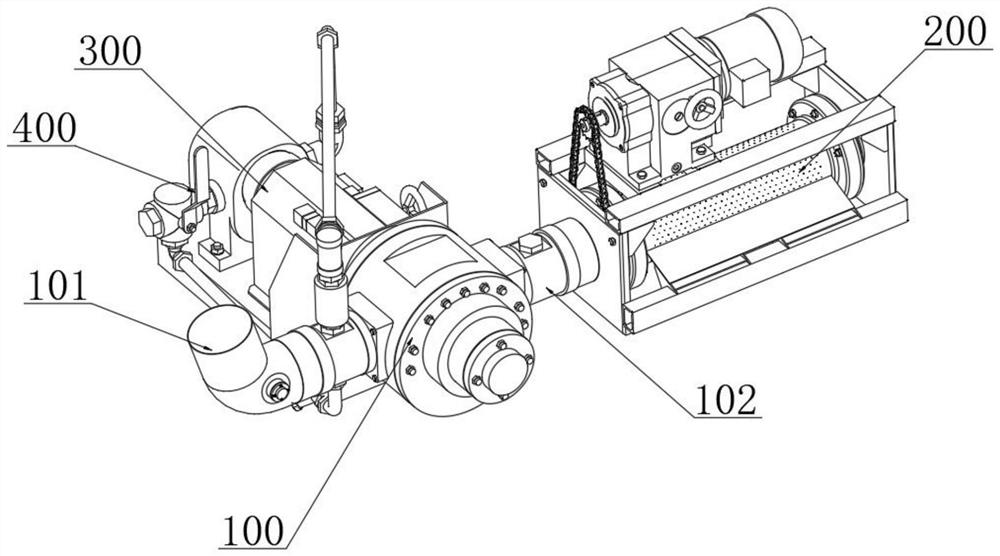

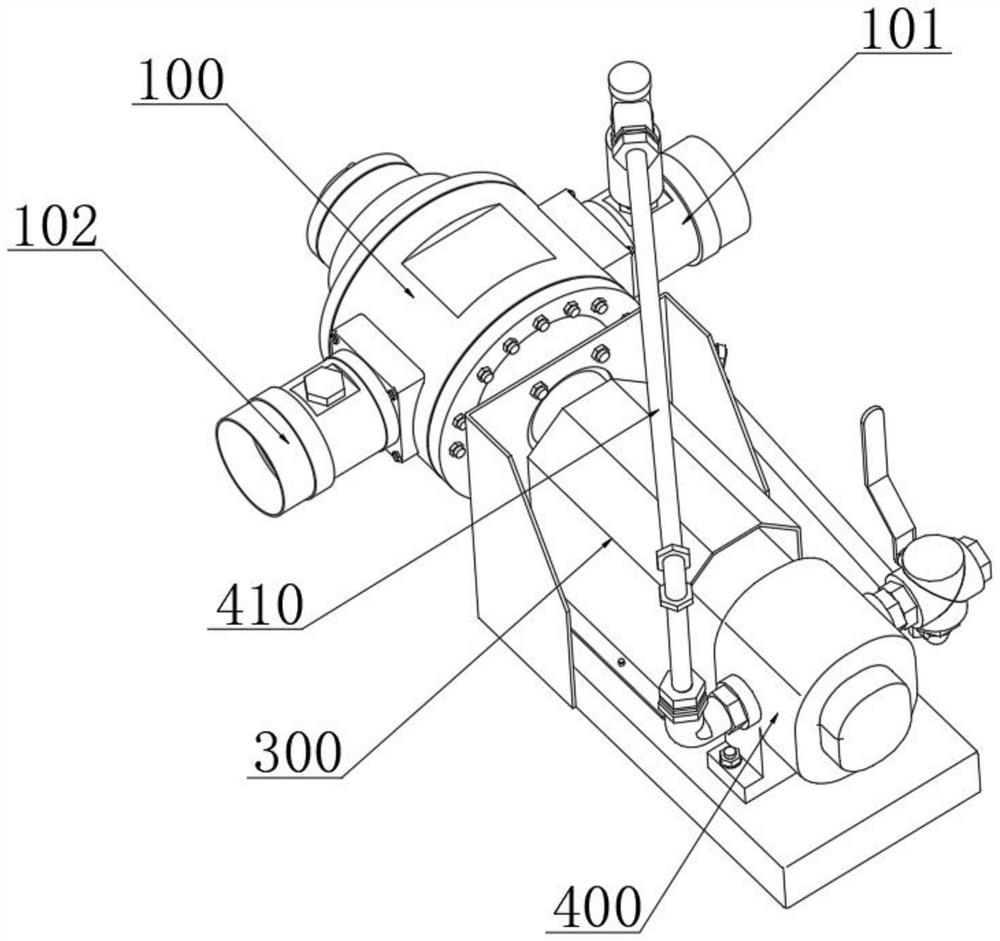

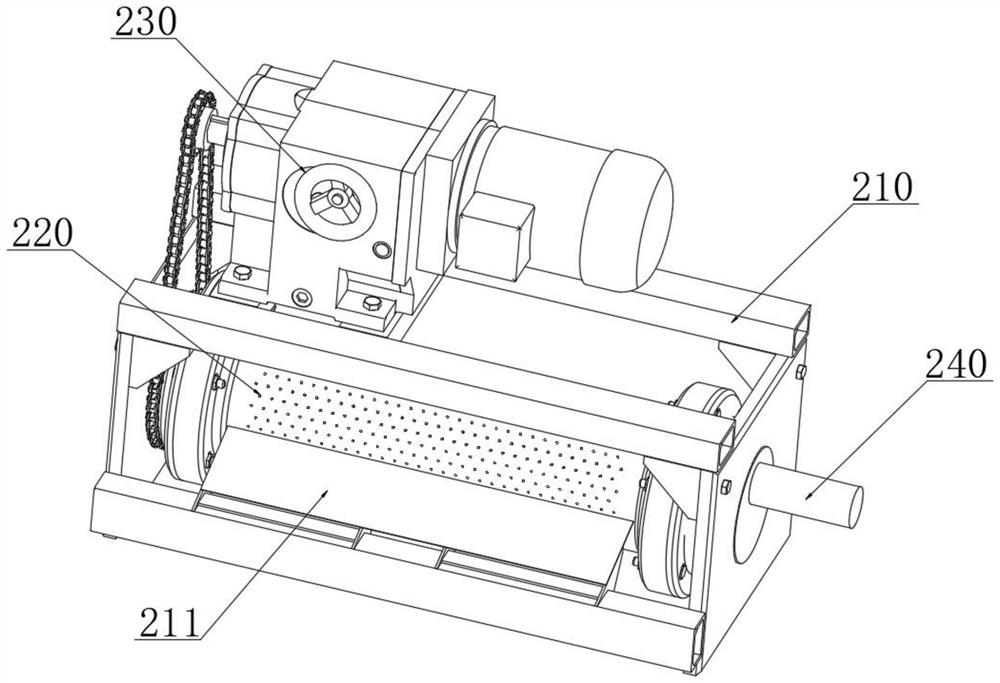

[0040] combine Figure 1-8 As shown in the figure, an energy-saving glue dispensing device for the production of silicone tape provided by the present invention includes: a preparation cabin 100, a coating mechanism 200, a dual-output motor 300,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com