Automatic feeding machine for packaging box

An automatic feeding and carton technology, applied in the direction of transportation and packaging, thin material handling, object separation, etc., can solve the problems that affect processing, cannot guarantee the continuity of feeding, and waste labor, so as to save costs and ensure the continuity of feeding , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

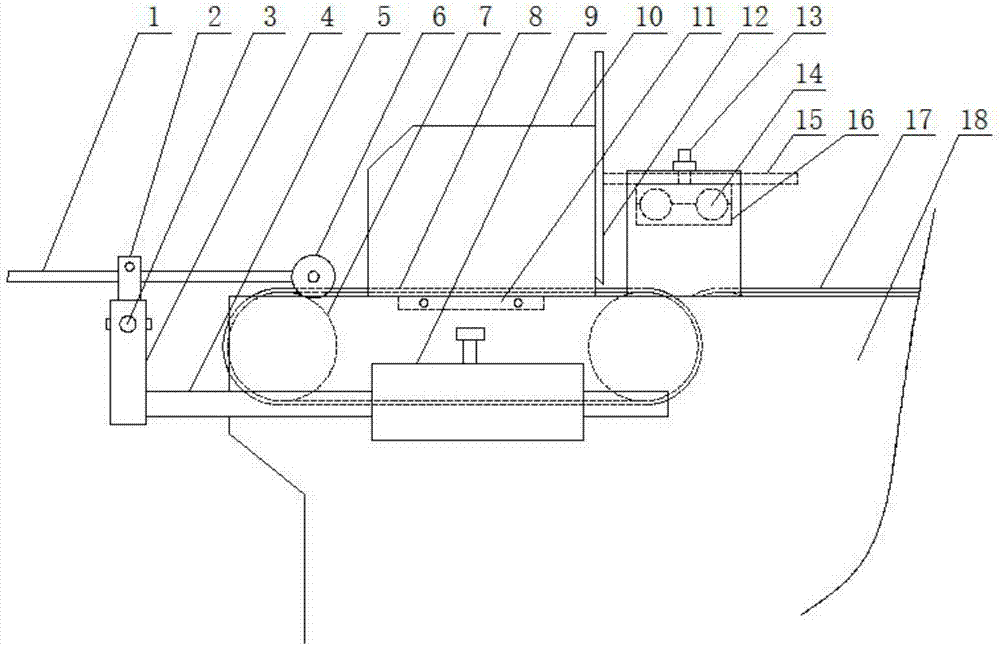

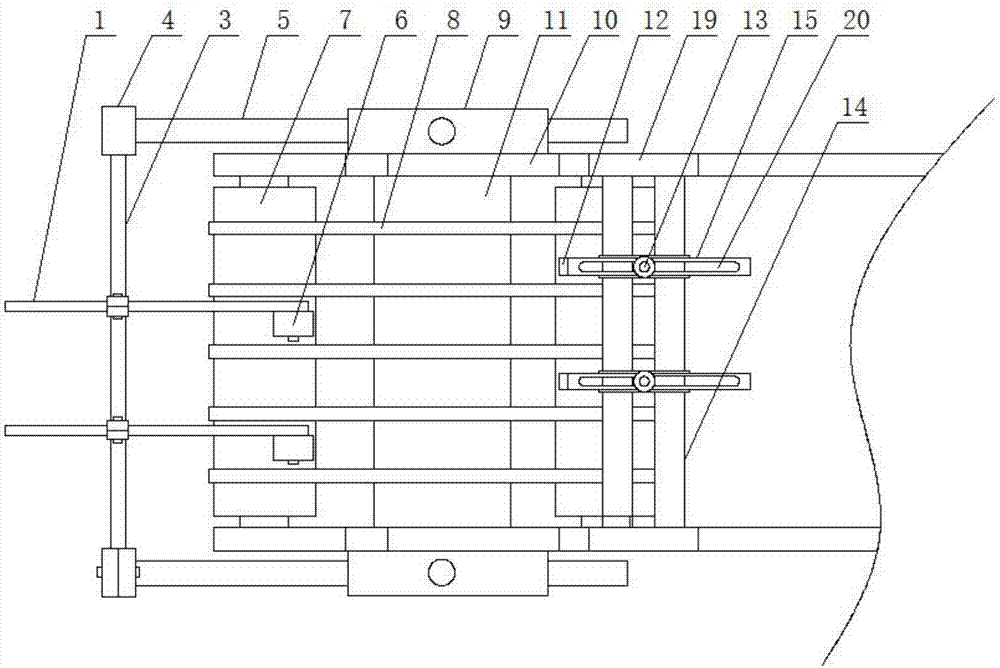

[0021] An automatic feeding machine for packaging cartons, the innovation of which is that it includes a frame 18, a motor, a drive roller 7, a conveyor belt 8, a stacking plate 11, an auxiliary feeding mechanism and a material blocking mechanism, and the frame is installed with There are two drive rollers driven by motors, and a stacking plate is installed on the frame between the two drive rollers, and a conveyor belt is wound on the two drive rollers and the stacking plate at intervals, and there are intervals on the drive roller at the front end of the frame. The linked auxiliary feeding mechanism is provided with a stopper mechanism at the rear of the drive roller at the rear end of the frame.

[0022] It also includes a baffle plate 10, and a baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com