Filling machine and filling process thereof

A technology of filling machine and process, applied in the field of canned food, which can solve the problems of inaccurate measurement of filling products, failure to timely inspect defective products, and insufficient weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

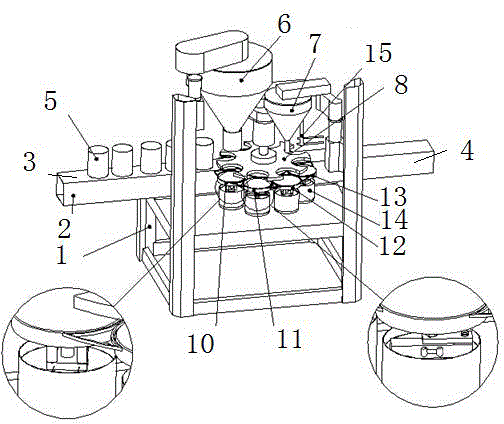

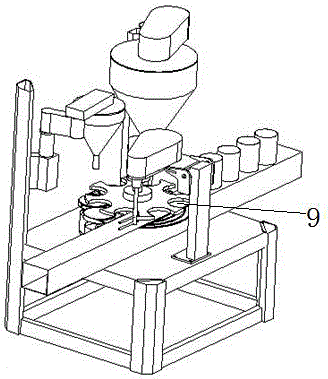

Image

Examples

Embodiment 1

[0021] The star-shaped turntable is circular, and there are 8 arc-shaped can card slots around the turntable body. The empty cans are transported to the star-shaped turntable through the conveying device, and the empty cans are inserted into the arc-shaped space of the star-shaped turntable. The tank body is stuck in the slot, and then rotates following the rotation of the star-shaped turntable. The empty tank is first filled with materials at the pre-filling station, and then weighed at the next station. Load-bearing, the weight ratio of the detection sensor, if there is an error between the weight of the tank body and the set filling material weight, it needs to be filled, then the supplementary filling will be carried out at the next station, and finally enter the secondary weighing station, if the product meets the set If the weight of the tank reaches the specified weight requirement, it is deemed to be a genuine product, and the tank body enters the conveying device and i...

Embodiment 2

[0023] Empty cans pass through the conveyor belt and enter the photoelectric detection station, and the arrival of empty cans is detected. If no empty cans arrive within 5 minutes, the machine enters the standby state. In the standby state, the star-shaped turntable stops rotating and the filling stops. When the cans arrive and start, if the empty cans accumulate within a certain period of time, the machine will automatically control the incoming cans to stop, by controlling the power output of the incoming cans facilities. The empty can enters the star-shaped turntable from the conveying device into the can-in station (that is, snaps into the arc-shaped tank body slot), and the star-shaped turntable spirally fills the empty can along the pre-filled hopper, and at the same time, the tray of this station is raised And vibrate, the vacuum cleaner will suck away the sprayed dust, after the filling stops, the tray will fall back to the position and the vibration will stop, the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com