Double-station and full-automatic rhinestone grinding and polishing machine

A fully automatic, double-station technology, applied in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

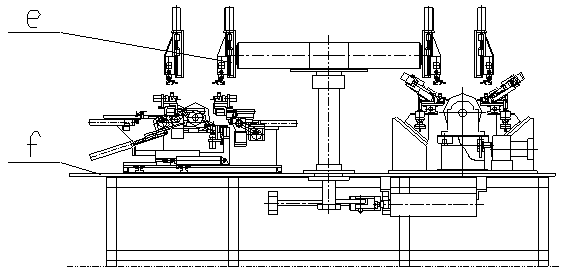

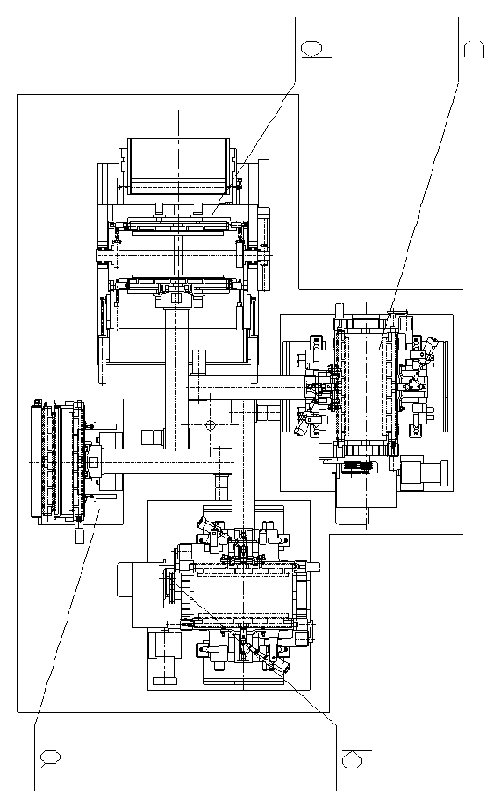

[0077] Embodiment one: see figure 1 with figure 2 , this double-station rhinestone automatic grinding and polishing machine includes a workbench (f), a beading station part (a), a grinding station part (b), a polishing station part (c), A docking and unloading station part (d) and a transfer manipulator part (e), characterized in that: the four directions of the worktable (f) are respectively arranged counterclockwise with the bead loading station part (a) , grinding station part (b), polishing station part (c) and docking and blanking station part (d), forming two circular grinding and polishing stations of the inner ring and the outer ring; The transfer manipulator part (e) is arranged in the middle of (f), which rotates back and forth within a range of 90 degrees around the main shaft of the manipulator, and can grasp the working needle row of the inner ring and the outer ring respectively.

Embodiment 2

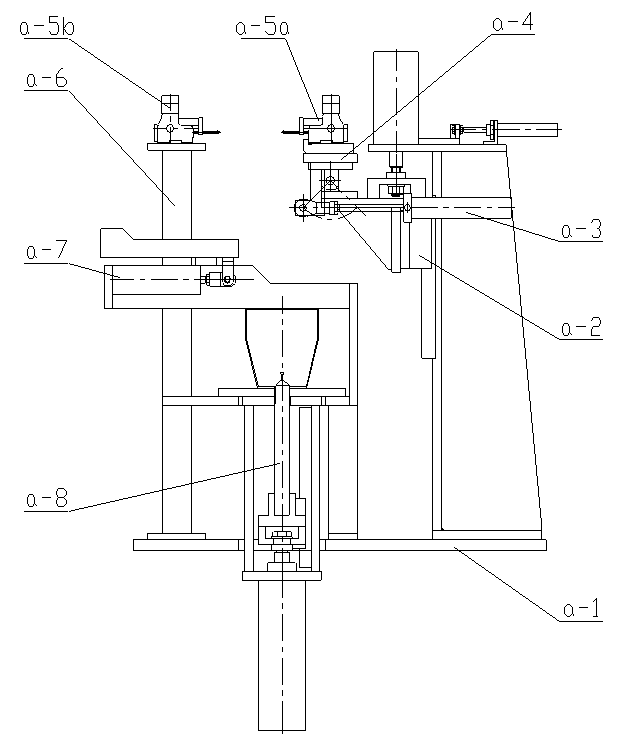

[0078] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: see image 3 , the bead loading station component (a) includes a large bottom plate (a-1) of the bead loading station, a needle row positioning keel assembly (a-4) and two needle rows (a-5a, a- 5b), on the large bottom plate (a-1), a set of lifting device (a-2) is fixedly installed on the inner ring, and the needle row positioning keel assembly is hingedly installed on the lifting device (a-2) ( a-4), the needle row positioning keel assembly (a-4) is placed on the needle row armor (a-5a) for inner ring work; two fixed installations are installed on both sides of the lifting device (a-2) An overturning component (a-3), under the action of the overturning component, the needle row positioning keel component (a-4) can be turned counterclockwise from the horizontal position to the vertical position; the upper outer ring of the large bottom plate (a-1) A rack assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com