Device for oxidized adjusting plutonium valence by N2O4

A valence state, oxidation column technology, applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., can solve the problem of reduced utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

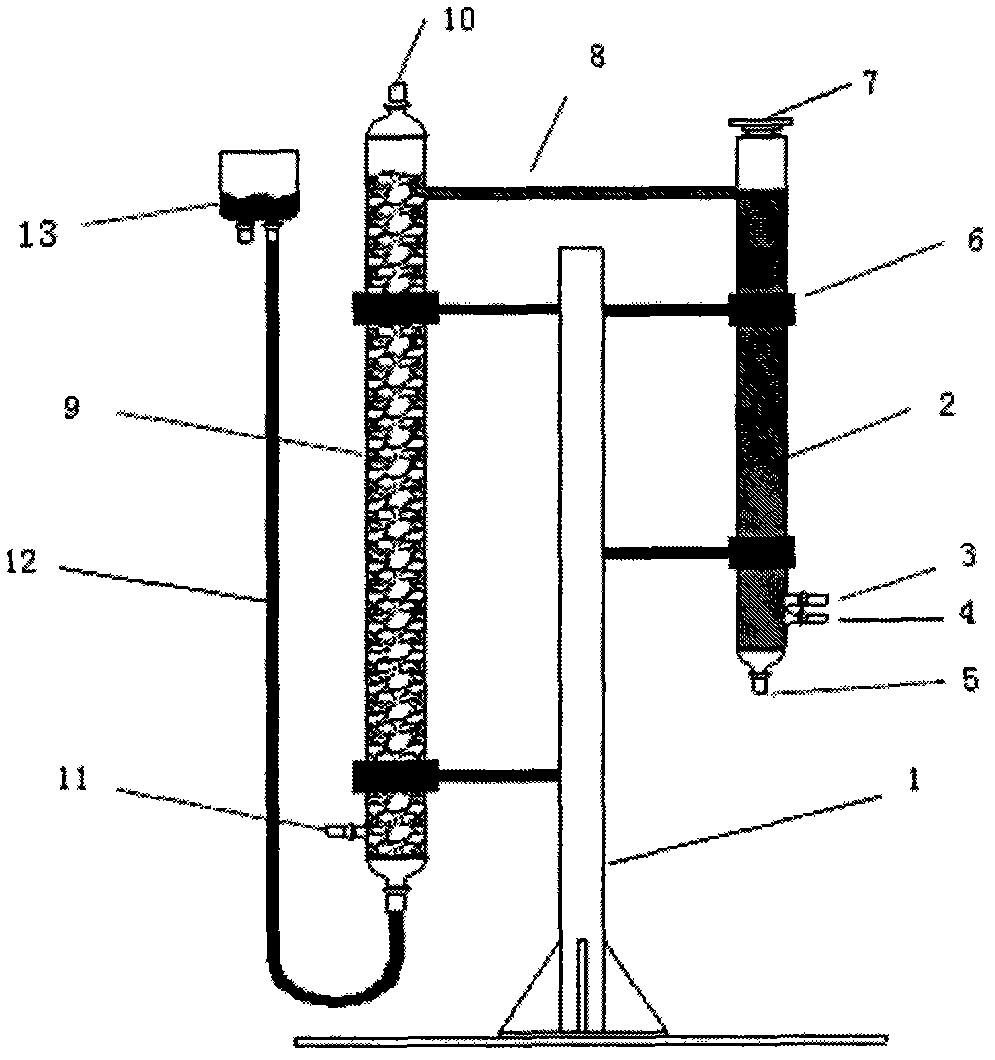

[0011] figure 1 It is the seasoning device provided by this embodiment. Among them, the Pu(III) oxidation column (2) is made of nitric acid corrosion-resistant materials such as glass or stainless steel, with a height of 400mm and a diameter of 20mm, and an inert ceramic ball filler with a diameter of 2mm is placed inside. bottom with liquid N 2 o 4 Inlet (3) and 1BP feed liquid inlet (4), wherein liquid N 2 o 4 The inlet (3) is located 10 mm above the 1BP feed liquid inlet (4). The feed liquid outlet at the upper end is 200mm in length, and the feed liquid delivery pipe (8) with a diameter of 4mm is connected with the nitrous acid removal column (9). Nitrous acid is driven out column (9) material is nitric acid corrosion resistant material such as glass or stainless steel, and height is 600mm, and diameter is 30mm, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com