Improvement of the purex method and uses thereof

A solvent phase and extraction technology, applied in the direction of reactors, recycling technology, reactor fuel elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

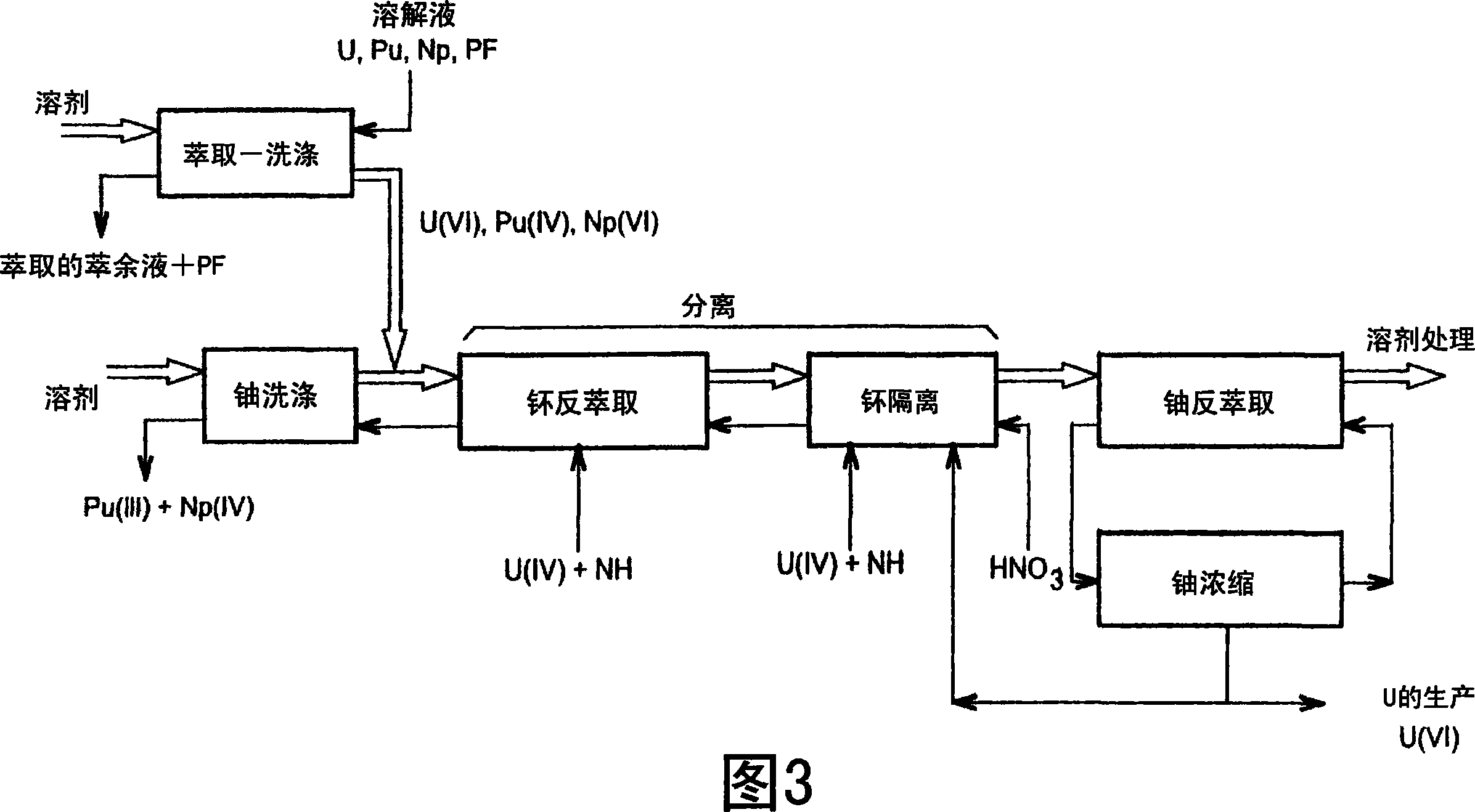

[0067] Reference is first made to FIG. 3 which shows a block diagram of a first exemplary embodiment of the method of the present invention, designed to allow stripping of neptunium(IV) during uranium / plutonium separation.

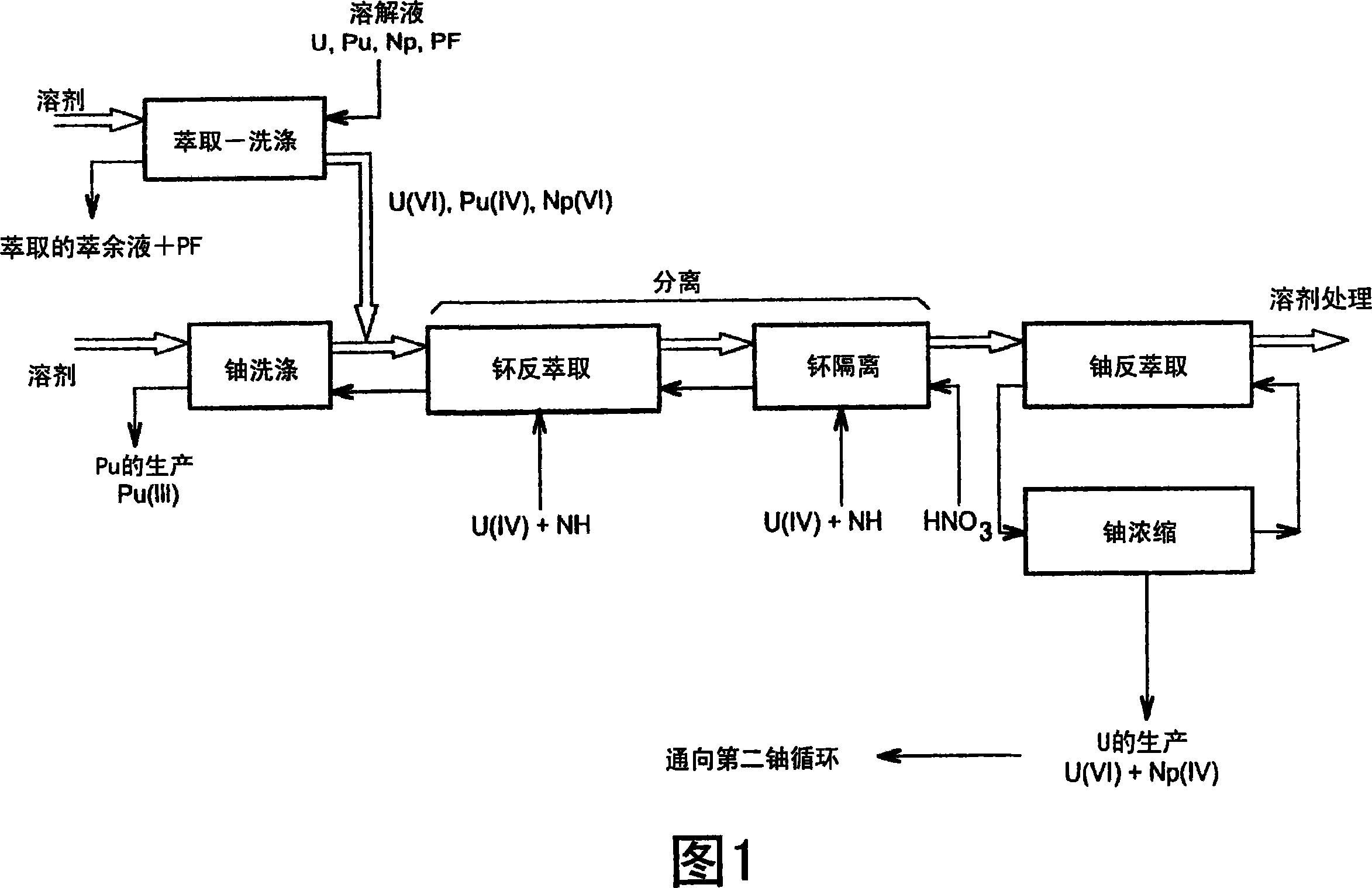

[0068] In this example, like the first purification cycle of the plutonium Rex process illustrated in Figure 1, the process of the present invention includes the following operations:

[0069] Co-extraction of uranium, plutonium and neptunium with oxidation state (VI), (IV) and (VI) respectively from the solution, the solution adopts the solvent composed of TBP in TPH with a concentration of 30% (v / v), The co-extracted solvent phase is then washed with aqueous nitric acid in order to complete the purification of uranium, plutonium and neptunium from fission products (“extraction-washing”);

[0070] ● Uranium / plutonium separation, which includes:

[0071] - reverse extraction of plutonium in oxidation state (III) from a solvent loaded with uranium, plutoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com