Recovery method for trace of uranium and/or plutonium in radioactive organic liquid waste

An organic waste liquid, radioactive technology, applied in the direction of radioactive purification, nuclear engineering, etc., to achieve the effect of recycling and reducing the amount of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

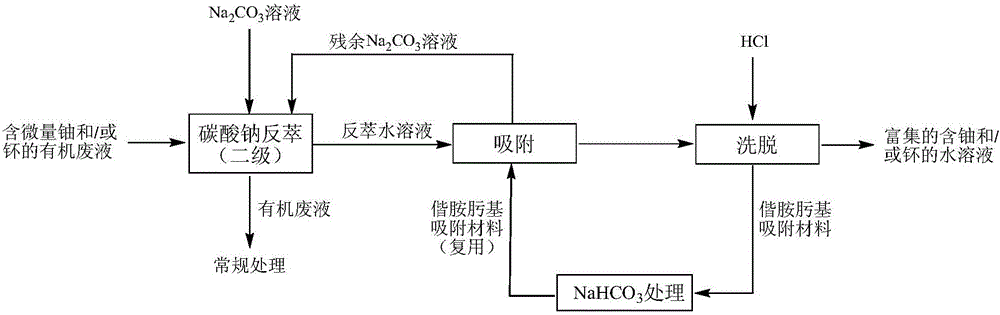

Method used

Image

Examples

Embodiment 1

[0033] (1) Materials and methods

[0034] 1. Experimental materials

[0035] Uranyl nitrate (UO 2 (NO 3 ) 2 ·6H 2 O, G.R.), ammonium uranyl carbonate ((NH 4 ) 4 [UO 2 (CO 3 ) 3 ], prepared according to the literature: Wu Keming, Solubility of Ammonium Uranyl Carbonate [J]. Atomic Energy Science and Technology, 1961,3(3):148-156. Sodium carbonate (Na 2 CO 3 ), tributyl phosphate (TBP), dodecane, ferrous ammonium sulfate, and hydroxylamine hydrochloride are commercially available reagents of analytical grade and used directly. Acrylic acid (AA) and acrylonitrile (AN) were commercially available reagents of analytical grade and were purified by vacuum distillation before use. Acrylamide (AAm) is a commercially available reagent of analytical grade and was purified by recrystallization before use. Polypropylene (PP, 20 mesh) powder was provided by Beijing Research Institute of Chemical Industry. Before use, it was extracted with acetone in a Soxhlet extractor for 24 h...

Embodiment 2

[0078]According to the literature (H.J.Zhang, H.L.Liang, Q.D.Chen, X.H.Shen.Synthesis of a new ionic imprinted polymer for the extraction of uranium from seawater[J].J.Radioanal.Nucl.Chem.,2013,298:1705-1712. ) to synthesize (2,4-dicarbonyl)-3-pentyl methacrylate, and use it as a functional monomer, ethylene glycol dimethacrylate as a crosslinking agent, and 1,4-dioxane as a solvent Preparation of imprinted polymers targeting uranyl ions. The screened 100-200 mesh polymer particles are packed into a column with a diameter of 10 mm, and the polymer filling height is 100 mm. The concentration of uranium is 35mg·L -1 The aqueous ammonium uranyl carbonate solution was used for column chromatography, and the flow rate was controlled at 10mL min -1 , every outflow 10mL sampling monitoring U(VI) concentration. When the presence of U(VI) is detected in the effluent, the total volume of the previous effluent is the breakthrough volume of the chromatographic column. The breakthrough...

Embodiment 3

[0082] According to literature (S.Das, A.K.Pandey, A.A.Athawale, V.Natarajan, V.K.Manchanda.Uranium preconcentration from seawater using phosphate functionalized poly(propylene) fibrous membrane [J].Desalin.Water Treat.,2012,38:114-120 .), grafted 2-(phosphoryloxy)ethanol methacrylate (PP-g-PEGMP) on the porous polypropylene membrane by gamma-ray irradiation method, the grafting rate was 93.5%, and in the grafted product The density of phosphoryloxy is 2.3mmol·g -1 . Cut into a circular membrane with a diameter of 55mm, as a filter membrane, the concentration of uranium is 35mg L -1 The aqueous solution of ammonium uranyl carbonate was filtered under pressure (the effective diameter of the membrane was 50mm), and the flow rate was controlled at 5mL·min -1 , monitor the concentration of U(VI) by sampling every 5mL outflow. When the presence of U(VI) is detected in the effluent, the total volume of the previous effluent is the breakthrough volume of the chromatographic column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com