Cassiterite ore separation method

A beneficiation method and ore technology, which are used in flotation, solid separation and other directions to achieve the effect of improving the total recovery rate of tin metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

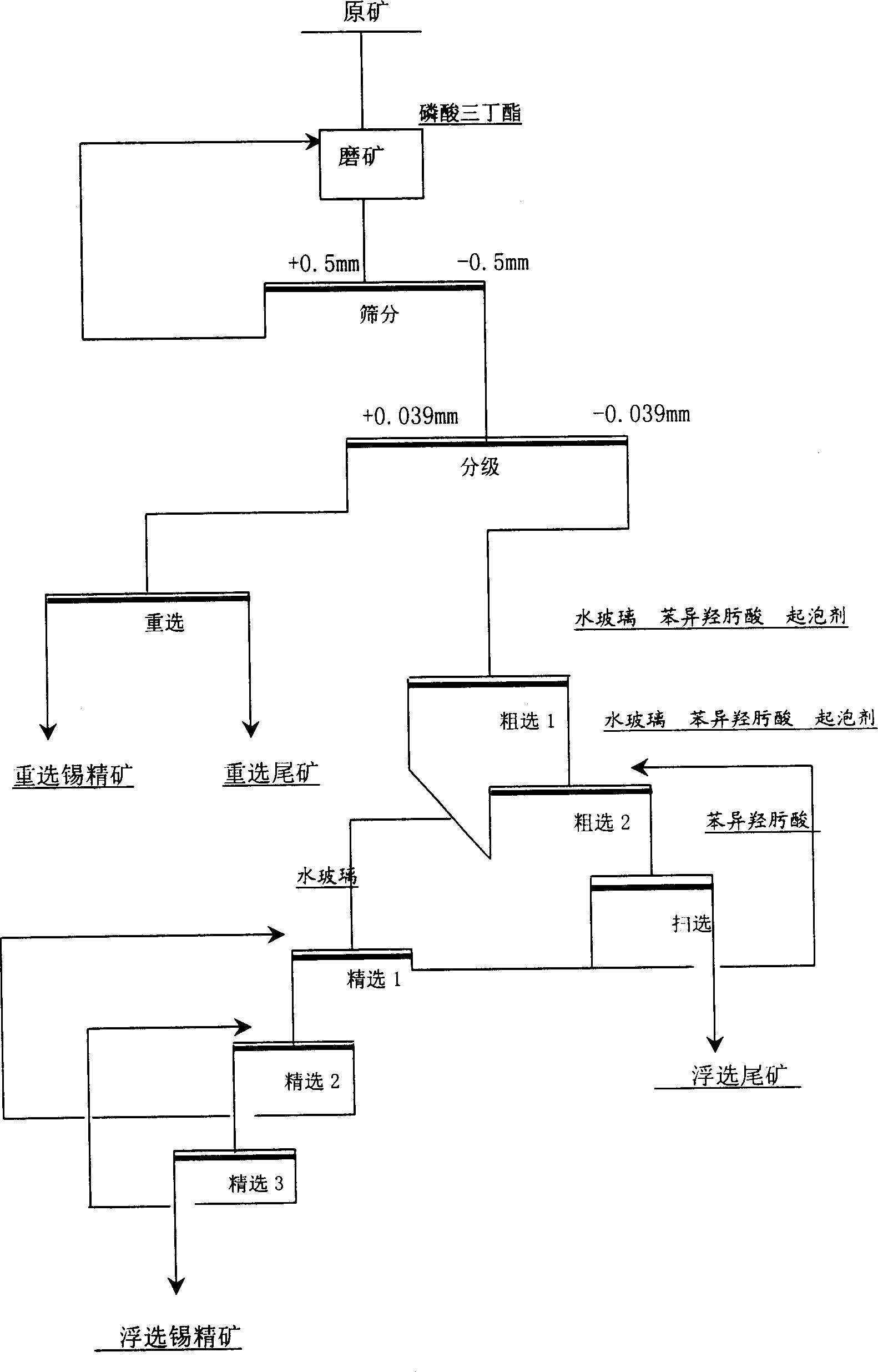

Image

Examples

Embodiment 1

[0015] Treatment containing Sn 1.1%, SiO 2 31.3%, CaCO 3 11.2% cassiterite-quartz vein type ore, the process system is: the particle size of the incoming grinding ore is less than 20mm, the grinding condition is a grinding concentration of 55%, the pH of the grinding system is controlled at pH 6.8; the ore and the flotation reagent triphosphate The butyl ester is added into the ore grinding machine for grinding, and the dosage is 60 grams per ton of raw ore. The part larger than 0.5mm returns to the grinding machine, the part larger than 0.5mm enters the cyclone for classification, and the part larger than 0.039mm adopts gravity separation (generally shaker equipment) to recover cassiterite, and the obtained tin concentrate grade (Sn ) is 54%, and the recovery rate of this part of tin is 80.3%.

[0016] For the fine particle fraction less than 0.039mm, the flotation method is used for recovery without desliming in advance. The flotation concentration is 28%. The process o...

Embodiment 2

[0018] Treatment containing Sn 0.9%, SiO 2 21.3%, CaCO 3 16.8% placer-type ore, the process system is: the particle size of the ore to be ground is less than 20mm, the grinding condition is a grinding concentration of 50%, the pH of the grinding system is controlled at pH 6.8; the ore and the flotation reagent tributyl phosphate Join the ore grinding machine together to grind ore, and the dosage is 90 grams / ton of raw ore. The part larger than 0.5mm returns to the grinding machine, the part larger than 0.5mm enters the cyclone for classification, and the part larger than 0.039mm adopts gravity separation (generally shaker equipment) to recover cassiterite, and the obtained tin concentrate grade (Sn ) is 58%, and the recovery rate of this part of tin is 84.3%.

[0019] As for the fine-grained part smaller than 0.039mm, it is directly recovered by flotation without desliming in advance. The flotation concentration is 26%, and the process of two roughing, one sweeping and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com