650V high-voltage aluminium electrolytic capacitor working electrolyte and preparation method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve problems such as low solubility, large product loss, and unsuitable production, and achieve low viscosity, high conductivity, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a working electrolyte for a 650V high-voltage aluminum electrolytic capacitor, comprising the following steps: 1) uniformly mixing a main solvent and an auxiliary solvent;

[0023] 2) Add 30%-40% solute at a temperature of 40-70 degrees Celsius, stir and heat up to 120-13-degrees Celsius;

[0024] 3) Raise the temperature to 130-150 degrees Celsius and add the flash voltage booster, and continue to heat up until the flash voltage booster dissolves;

[0025] 4) After the flash voltage is completely dissolved, cool to 125-135 degrees Celsius, add the remaining solute, and keep warm for 60-90 minutes;

[0026] 5) Cool to 100-105 degrees Celsius and add other additives.

Embodiment 1

[0028] As shown in Table 1, the working electrolyte of the 650V high-voltage aluminum electrolytic capacitor of this embodiment includes 75% ethylene glycol, 5% nano-silica solution, 5% glycerin, 6.5% ammonium sebacate, 2% Mannitol, 0.5% ammonium 1,7-dodecanoate, 3% boric acid polyethylene glycol polyester, 2% polyvinyl alcohol, 0.5% ammonium hypophosphite and 0.5% p-nitrobenzyl alcohol , the above is the mass percentage. When preparing, mix and heat 75% ethylene glycol, 5% nano-silica solution, and 5% glycerin to 40-50°C by mass percentage, add 3% ammonium sebacate, 2% mannitol and 0.5% 1,7 - Ammonium dodecanoate. Continue heating to 130-135°C, add boric acid polyethylene glycol polyester 3%, polyvinyl alcohol 2%, add until dissolved, then cool down to 125-135°C, add 3.5% ammonium sebacate, and keep warm for 60min. Cool to 100-105°C, add 0.5% each of ammonium hypophosphite and p-nitrobenzyl alcohol, and the configuration is complete.

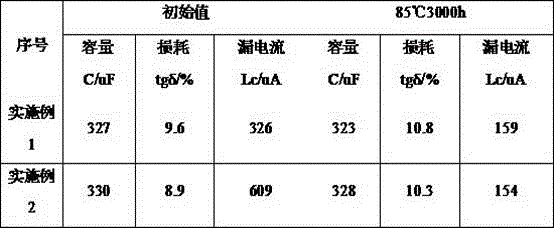

[0029] The parameters and performance...

Embodiment 2

[0031]As shown in Table 1, the working electrolyte of the 650V high-voltage aluminum electrolytic capacitor of this embodiment includes 55% ethylene glycol, 10% polyethylene glycol, 5% diethylene glycol monobutyl ether, and 6% nano Silica solution, 7% ammonium sebacate, 3% sebacic acid, 1% mannitol, 3% citric acid, 1% ammonium 1,7-dodecanoate, 2% boric acid, 3% polyvinyl alcohol, 2% sodium tetraborate, 1% ammonium hypophosphite and 1% p-nitrobenzyl alcohol; the above are mass percentages. When preparing, mix and heat 55% ethylene glycol, 10% polyethylene glycol 400, 5% diethylene glycol monobutyl ether, and 6% nano-silica solution to 40-50 °C, and add 3 % ammonium sebacate, 3% sebacic acid, 1% mannitol and 1% ammonium 1,7-dodecanedioate. Continue heating to 130-135°C, add 2% boric acid, 3% polyvinyl alcohol, 2% sodium tetraborate, add until dissolved, then cool down to 125-135°C, add 4% ammonium sebacate, 3% citric acid , and keep warm for 70min. Cool to 100-105°C, add 1% e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com