Technology for extracting Gallium metal from lead-zine tail ore slug smelting by extracting-electrolytic method

A technology for metal extraction and electrolysis, which is used in the improvement of process efficiency, photography technology, instruments, etc., can solve problems such as non-recycling and loss, and achieve the effects of environmental protection, low price and reduction of processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

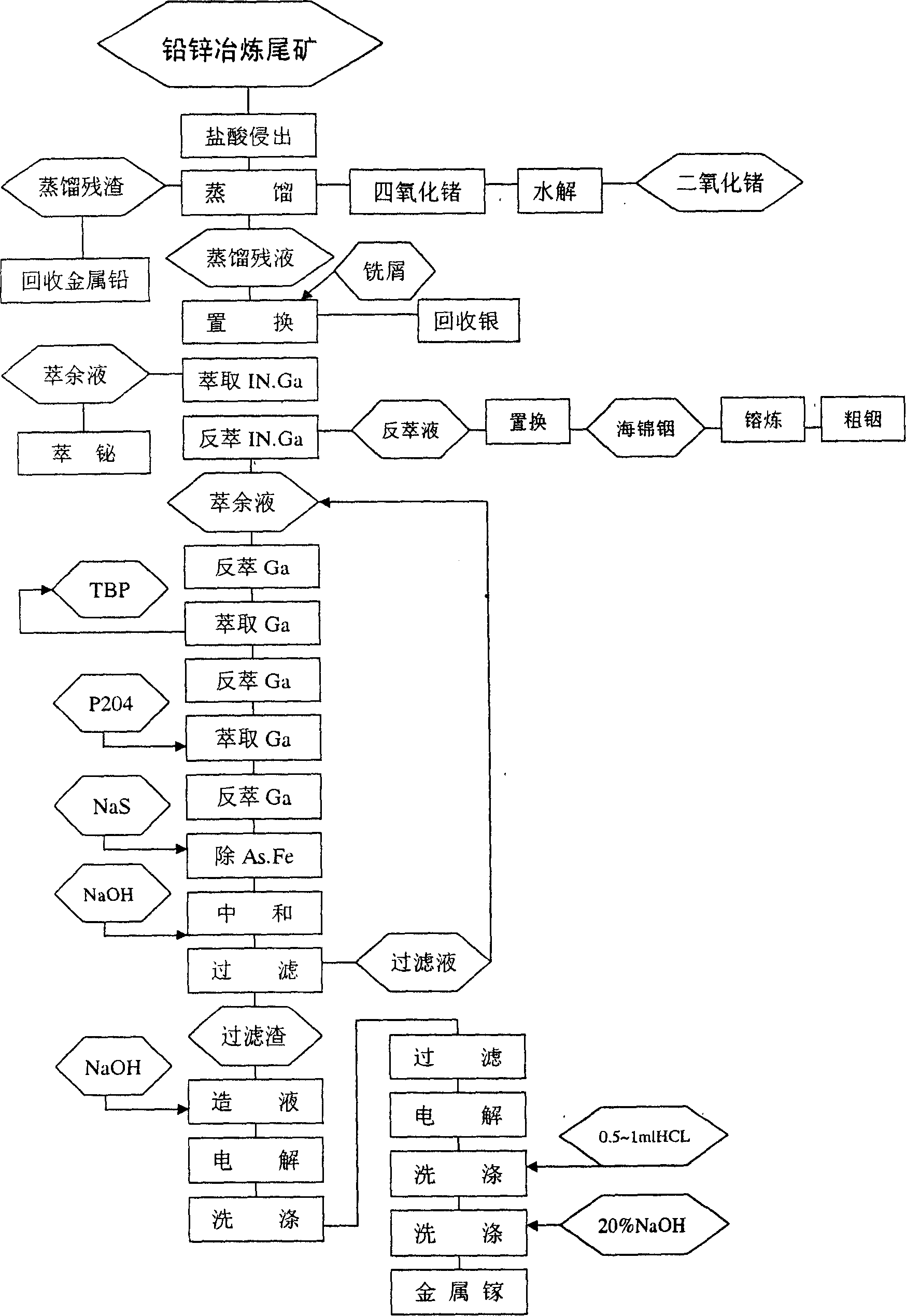

[0018] See figure 1 This specific embodiment uses lead-zinc smelting tailings in Shaoguan, Guangdong Province as raw materials. The lead-zinc ore produced in Shaoguan is generally accompanied by germanium, indium, and gallium. The final vacuum of pyrometallurgical smelting in lead-zinc smelting Both the slag and the replacement slag of the hydrometallurgical process enrich the germanium, indium, and gallium in the original ore. The general grade reaches: Ge: 0.6-3%, In: 0.2-0.6%, Ga: 0.1-0.4%. These materials are crushed, dried, leached with concentrated hydrochloric acid, and then chlorinated and distilled in a reactor. The distilled gas is collected and condensed into liquid germanium tetroxide. After germanium tetroxide is hydrolyzed, crude germanium dioxide is obtained. Germanium is further processed into metal germanium; after distillation and filtration, the filter cake is a material containing lead, which can be sent to lead refinery for lead smelting. The indium and galliu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com