Method for treating high-concentration organic waste water in acroleic acid production

A wastewater treatment, acrylic technology, applied in natural water treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as corrosion of pipelines and blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An acrylic acid factory diverts high-concentration wastewater from the production process and uses supercritical water oxidation technology for treatment. Wastewater COD Cr The concentration is 10000mg / L, the salt is 3000mg / L, and the wastewater from acrylic acid production is treated under the following conditions, with a daily treatment capacity of 0.5m 3 / d:

[0025] (1) The electric heating method is adopted in the preheating stage, and the preheating temperature is 300°C;

[0026] (2) The main reactor adopts coil electric heating, and the temperature of the reactor is controlled at: 600°C;

[0027] (3) The oxidant uses 30% hydrogen peroxide, and the flow rate of waste water, clear water, and oxidant inflow is controlled at 10:5:1. A proper amount of catalyst MnO can be added into the water 2 / γAl 2 o 3 , the concentration is about 10mg / L.

[0028] (4) Reaction pressure: 25Mpa.

Embodiment 2

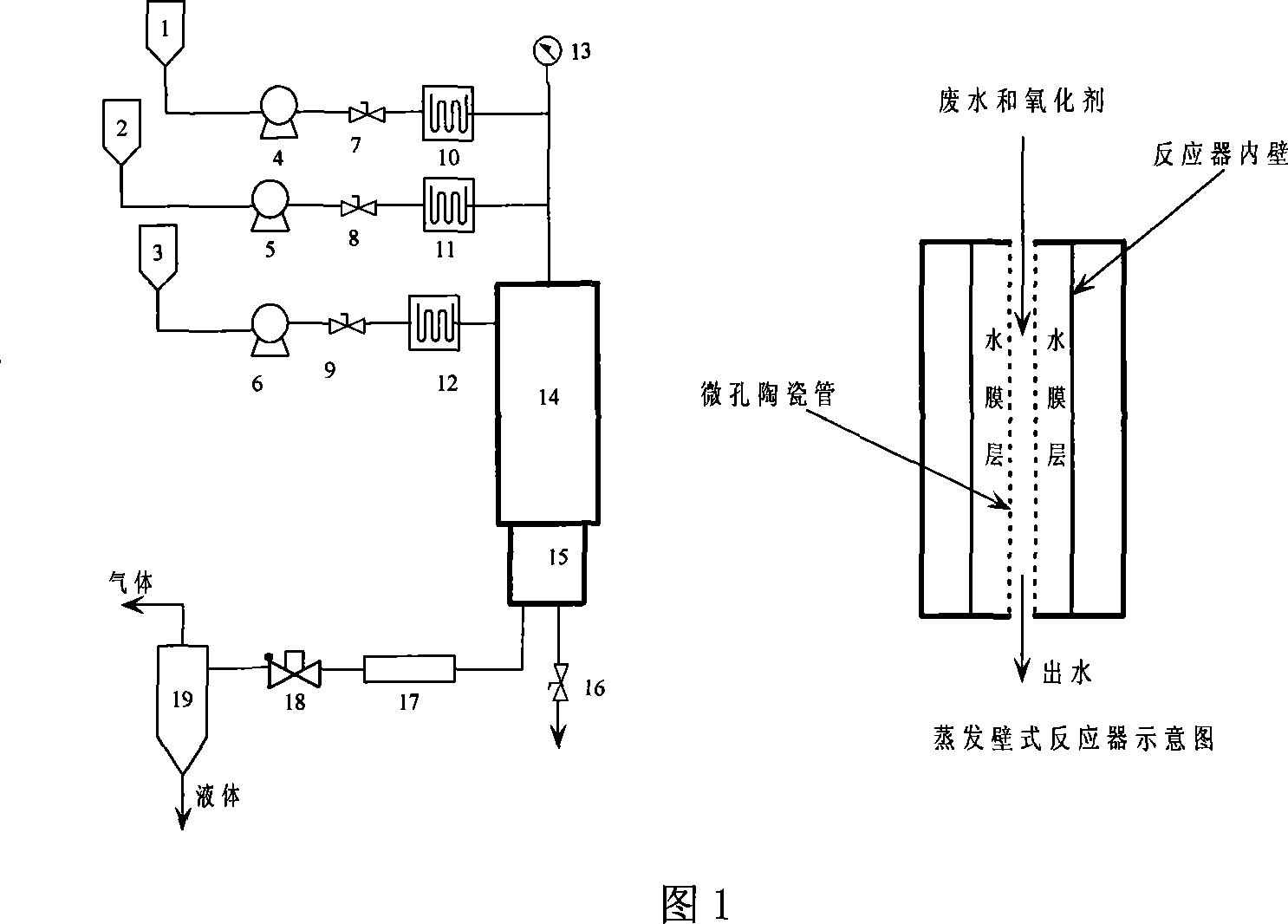

[0030] An acrylic acid factory treats the high-concentration part of the wastewater in the production process separately, with a daily treatment capacity of 0.5m 3 / d, waste water COD Cr Concentration is 50000mg / L, salt 3000mg / L, Cl-5000mg / L. The factory uses the SCWO process to treat this waste water. In order to reduce the corrosion of equipment during the treatment process, the evaporation wall supercritical water oxidation technology is adopted, including the following conditions:

[0031] (1) Place acrylic acid production wastewater, oxidant and clear water in the wastewater and clear water tanks respectively, and add MnO to the wastewater 2 / γAl 2 o 3 As a catalyst, the concentration is 10-20mg / L;

[0032] (2) Electric heating is used in the preheating stage, and the preheating temperature is 300°C;

[0033] (3) The temperature of the main reactor is heated by electric coil, and the reaction temperature is kept at about 480°C;

[0034] (4) The oxidant uses 30% hydr...

Embodiment 3

[0037] An acrylic acid plant treats the high-concentration part of the wastewater in the production process separately, with a daily treatment capacity of 0.3m 3 / d, waste water COD Cr The concentration is 100000mg / L, and the salt is 30000mg / L. The factory uses the SCWO process to treat this waste water. In order to reduce the corrosion of equipment during the treatment process, the evaporation wall supercritical water oxidation technology is adopted, including the following conditions:

[0038] (1) Electric heating is used in the preheating stage, and the preheating temperature is 400°C;

[0039] (2) The temperature of the main reactor is heated by electric coil, and the reaction temperature is kept at 600°C;

[0040] (3) The oxidant uses 30% hydrogen peroxide, and the flow rate of waste water, clear water, and oxidant inflow is controlled at 1:1:1. A proper amount of catalyst MnO can be added into the water 2 / γAl 2 o 3 , the concentration is about 20mg / L;

[0041] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com