Method for preventing corrosion and marine creature fouling on ship propeller

A technology of propellers and marine organisms, applied in chemical instruments and methods, hulls, ship construction, etc., can solve the problems of easy damage of organic paint coatings, short service life, and inability to provide long-term effective protection, and achieve the goal of solving the problems of marine organisms Fouling, low porosity, and the effect of solving propeller corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

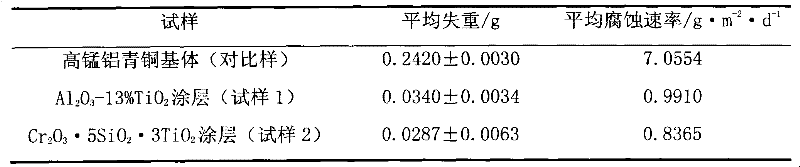

[0011] Using high manganese aluminum bronze (ZQA112-8-3-2) for propellers as the base material, sandblasting the surface of the base before spraying to remove scale and obtain a uniform and rough surface, and then adopt thermal spraying methods such as plasma spraying methods to prepare sequentially Bond coats, metal oxide ceramic insulating coatings and metal antifouling coatings on surfaces.

[0012] Preparation of bonding coating: self-bonding aluminum bronze powder is used, the powder particle size is 40-104 μm, and the weight percentage of main components is: Al: 10.4%; Fe: 0.52%; Cu: balance. Prepared by plasma spraying, the coating thickness is about 60μm.

[0013] Metal oxide ceramic insulating coating: Spray two ceramic insulating coatings on the bonding coating, one material is Al 2 o 3 -13%TiO 2 (Sample 1), the percentage by weight of coating powder composition is: TiO 2 : 13.2%; SiO 2 : O.5%; Al 2 o 3 : The balance, the powder particle size is 20-40μm; the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com